Atress testing device for cycloid pin tooth meshing

A test device and cycloidal needle technology, applied in the direction of measuring device, machine gear/transmission mechanism test, mechanical component test, etc., can solve the problems of high cost of comprehensive test test bench, unsuitable for special test, complicated design, etc., to achieve Reduce the experimental steps and test cycle, good market prospects, reduce the effect of material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

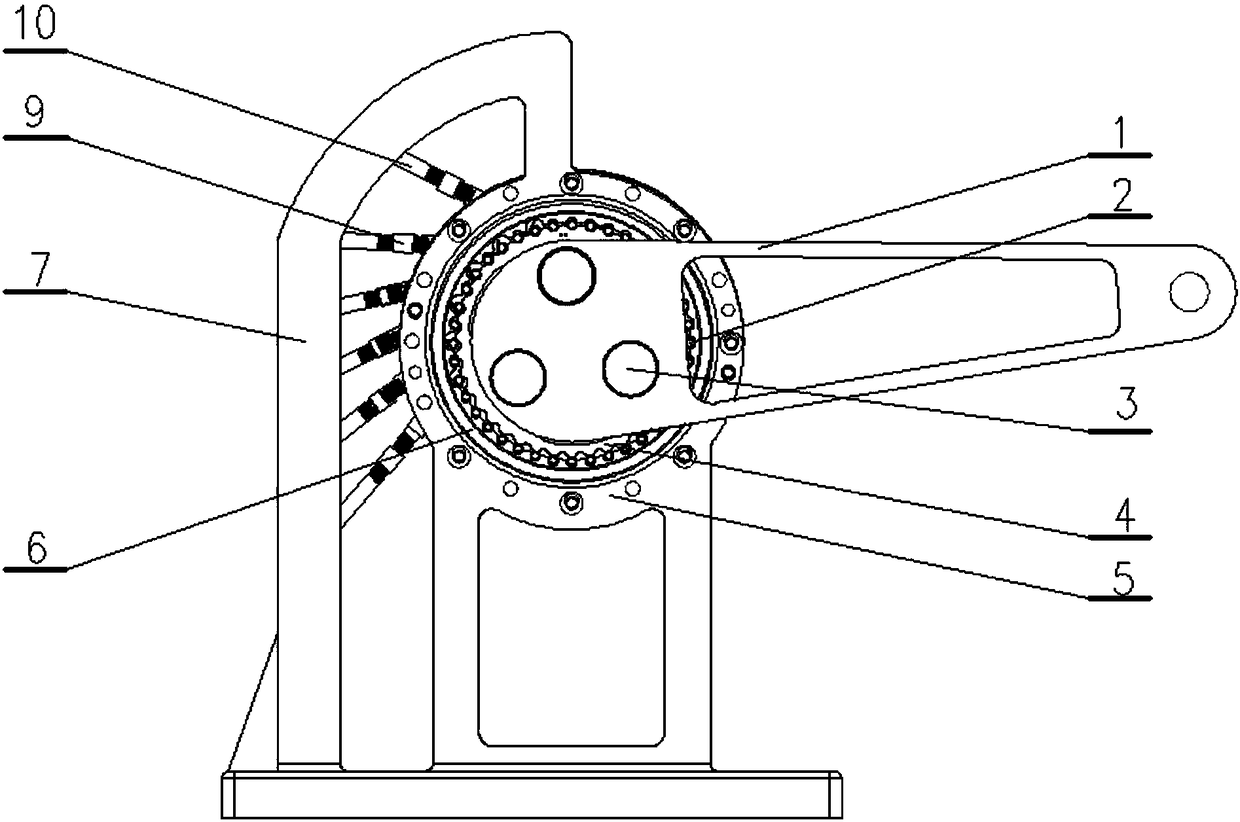

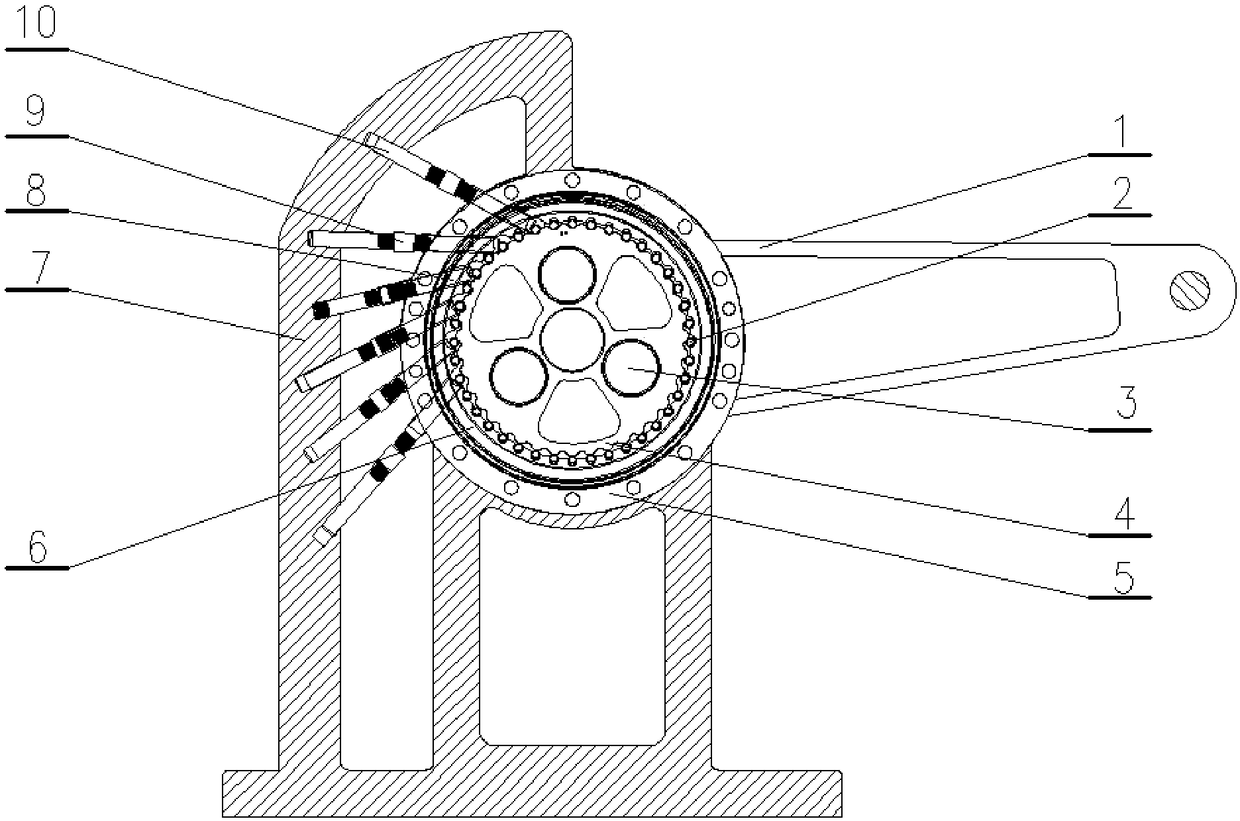

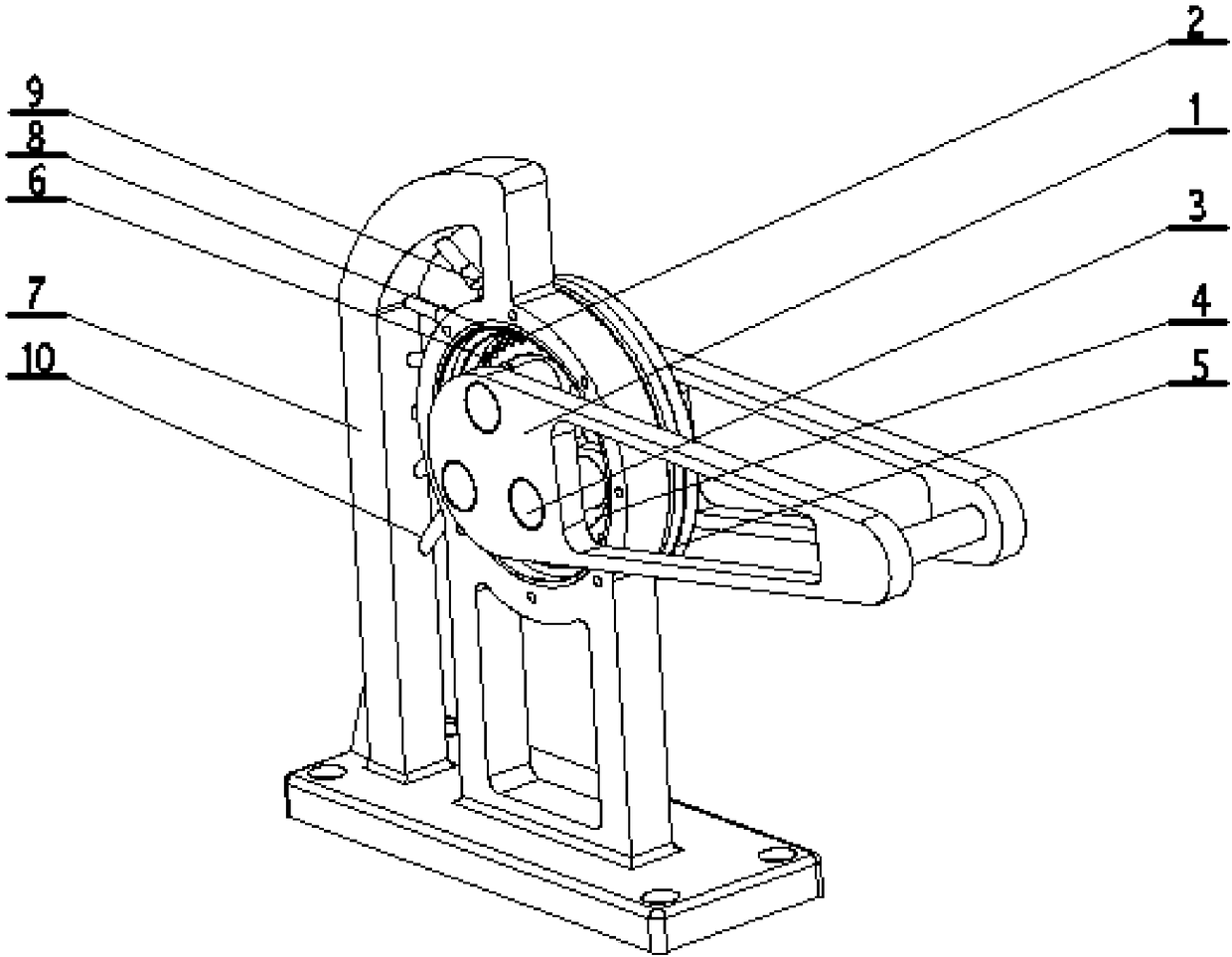

[0041] Such as Figure 1 to Figure 3 As shown, the precision reducer cycloidal pin gear dynamometer test bench includes a lever 1, a cycloidal pin gear mechanism, a test bench support 7, a force transmission pin 8, a force sensor 9, and a threaded rod 10; the cycloidal pin The gear mechanism includes pin teeth 2, cycloid wheel 4, flange 5 and pin gear housing 6, pin teeth 2 and cycloid wheel 4 are fixed inside the pin gear housing 6, and are assembled through flange 5 to form a cycloid needle gear mechanism; where:

[0042] The lever 1 and the cycloidal pin gear mechanism form the force-measuring input end, and the pin gear housing 6 of the cycloid pin gear mechanism is fixed on the test bench support 7 through threaded connection, and its installation position corresponds to the angle and position of the force sensor 9; The tooth 2 and the cycloidal wheel 4 are fixed inside the pin gear housing 6, and are fixed through the matching assembly of the flange plate 5, and the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com