Radiator using double-sided high-efficient water-cooled spiral structure to improve efficiency

A technology of spiral structure and radiator, which is applied in the direction of cooling/ventilation/heating transformation, electrical equipment structural parts, electrical components, etc., can solve the problems of increased flow resistance of water channels, radiator failure, solder blockage, etc., to increase disturbance , Reduce thermal resistance and prevent corrosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

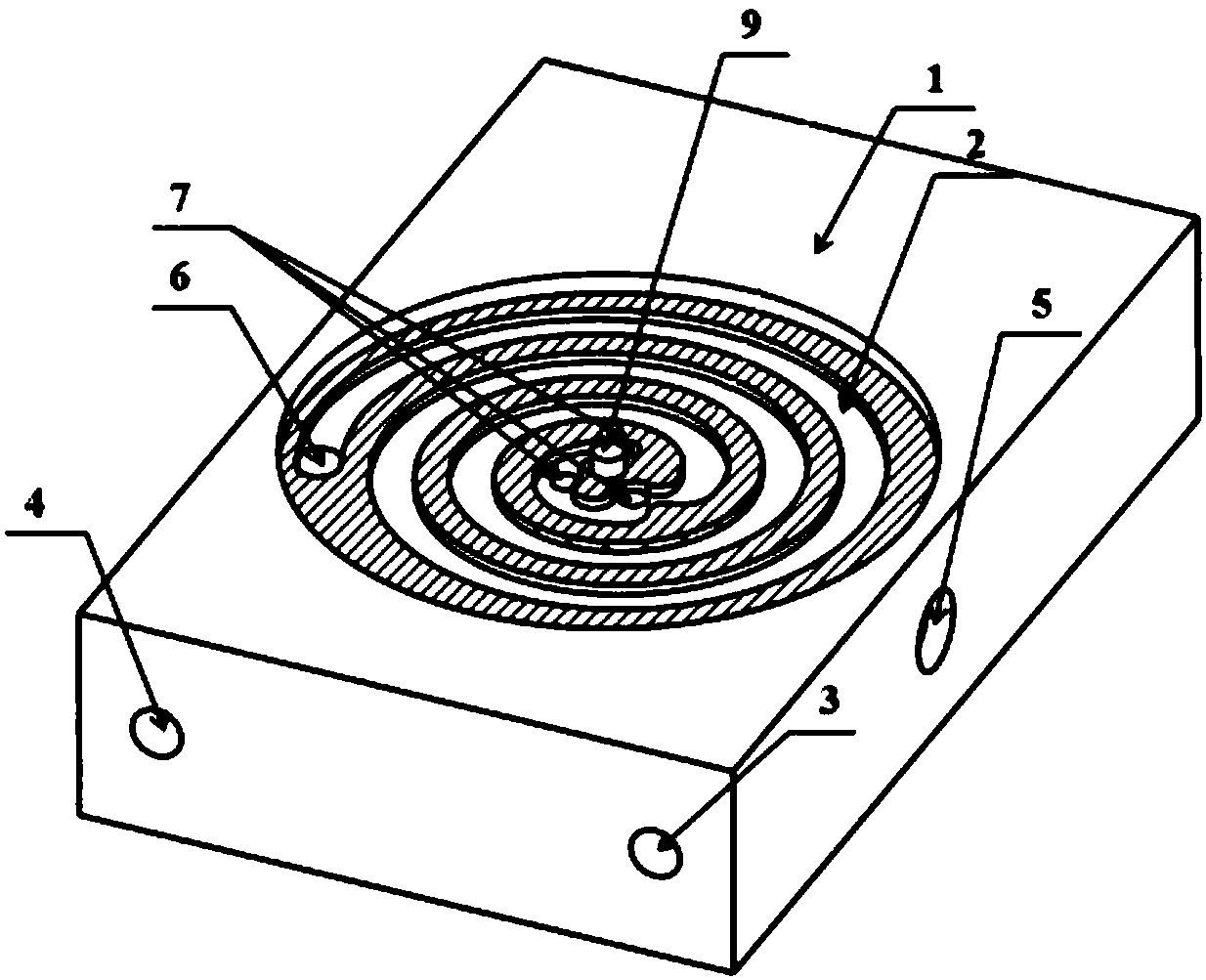

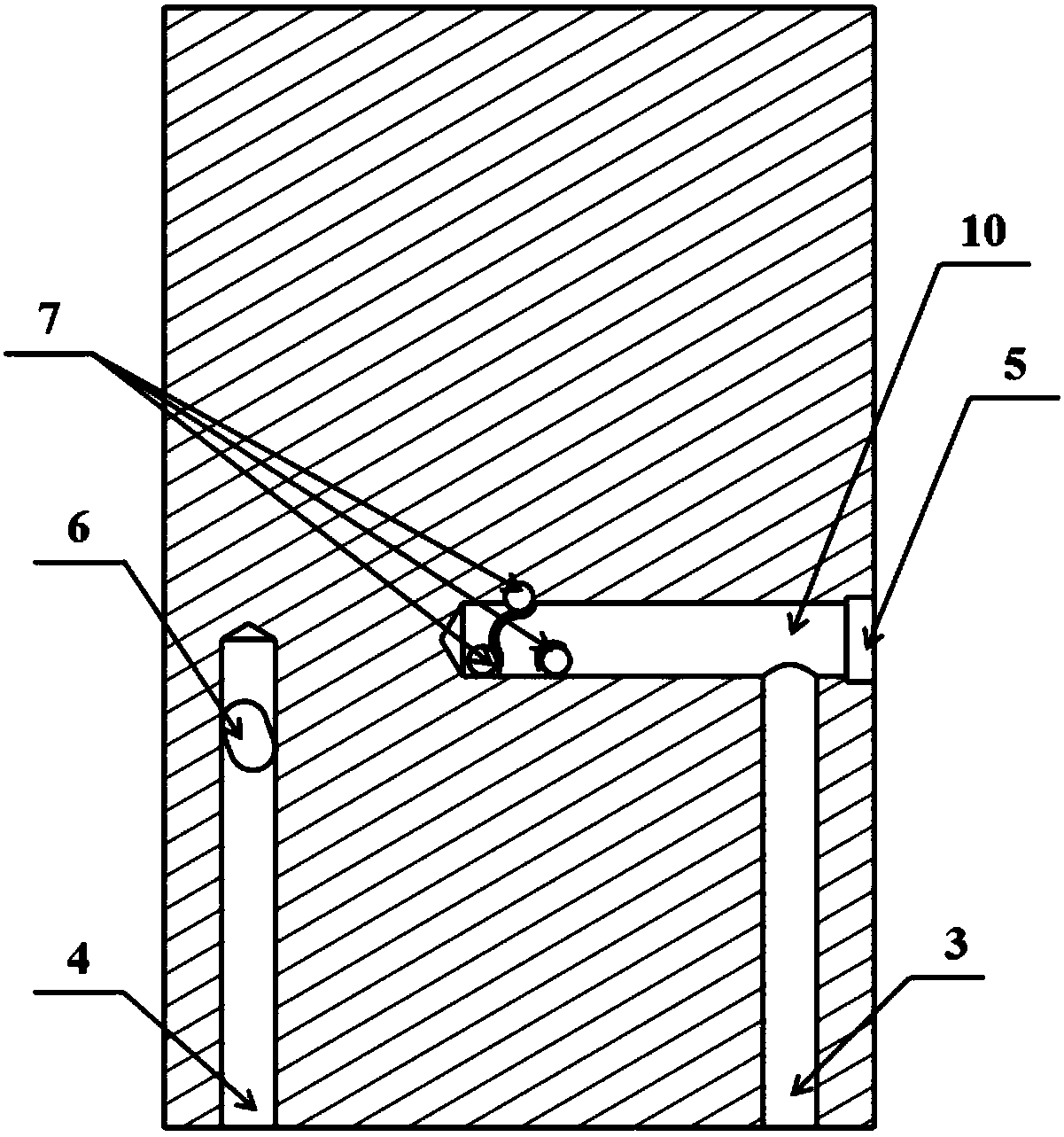

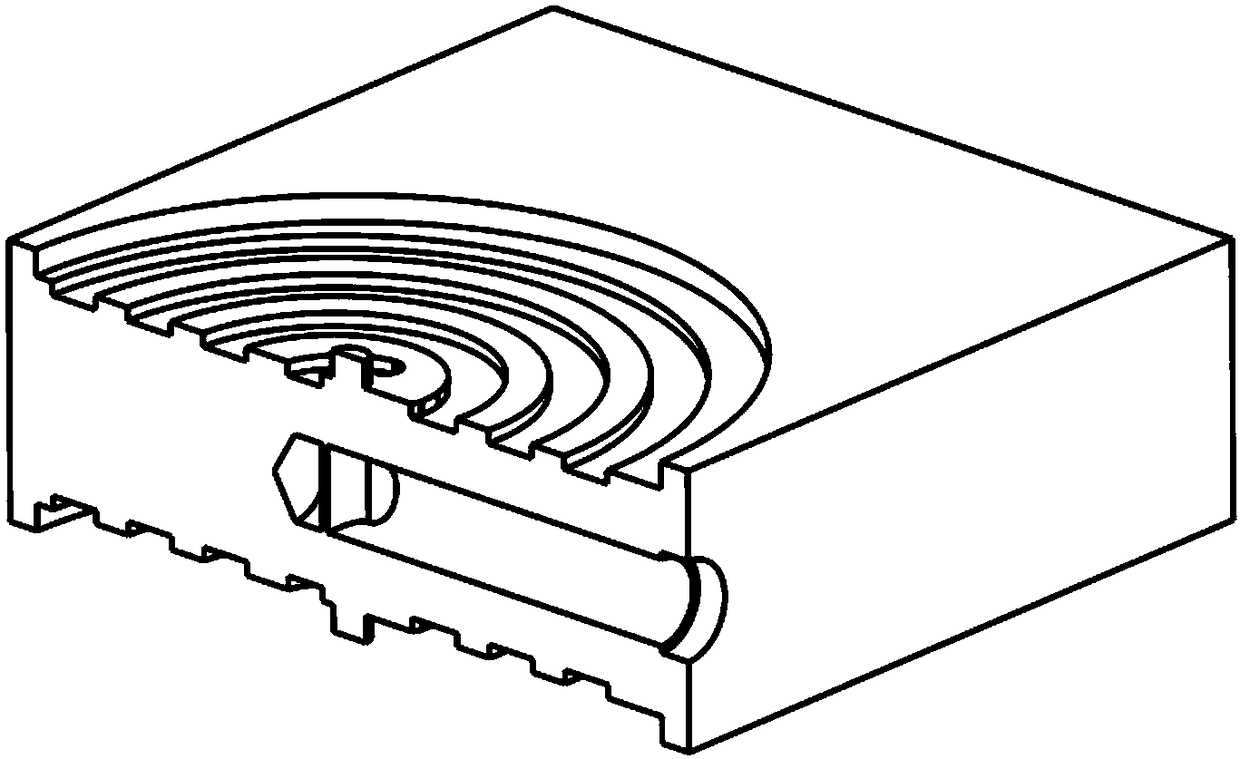

[0020] A heat sink that utilizes a double-sided high-efficiency water-cooled spiral structure to improve efficiency, including a base plate 1, a first cover plate 11 and a second cover plate 12, such as Figure 4 shown;

[0021] There are circular grooves on the surface of the substrate 1, preferably, circular grooves are formed on both opposite surfaces of the substrate 1, and the first cover plate 11 is fastened with the circular grooves, such as Figure 1-3 shown;

[0022] Preferably, the substrate 1 and the cover material 11 are made of aluminum alloy, which has good heat dissipation performance and low price, thereby improving performance while reducing production cost;

[0023] The bottom surface of the circular groove is provided with a water-cooling passage 2, and the water-cooling passage 2 is a spiral groove. One end of the water-cooling passage 2 is provided with a first diversion hole 7, and the other end is provided with a second diversion hole 6 to prevent adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com