Manufacturing process of braised chicken

A production process and grilled chicken technology, which is applied in food coating, the function of food ingredients, food ingredients as taste improvers, etc. It can solve the problems of taste reduction, reduced sales of grilled chicken, and destruction of original flavor, etc., to achieve a fresh taste , strong flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

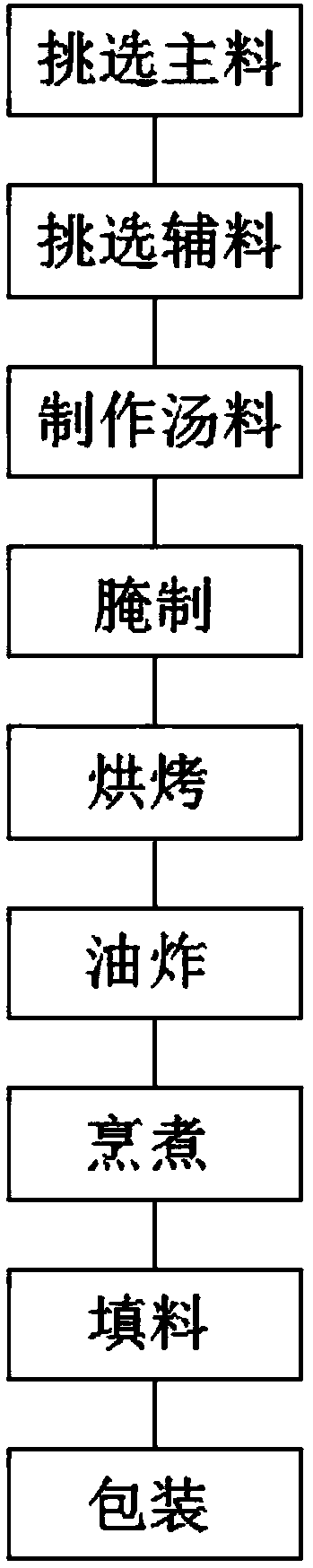

[0022] The present invention provides such figure 1 A kind of manufacture craft of braised chicken shown, its manufacture craft is as follows:

[0023] Step 1: Select the main ingredients: select the native chicken from the farm, enter the factory for inspection, then slaughter, depilate, open and eviscerate, and finally tie the whole body of the chicken with holes for later use;

[0024] Step 2: Select auxiliary materials: In terms of mass components, choose 2 parts of amomum, 3 parts of cloves, 1 part of jade fruit, 2.5 parts of cassia sticks, 3 parts of angelica dahurica, 2 parts of cinnamon, 1.5 parts of Luo Han Guo, 6 parts of ginger, reed rhizome 2 parts, 2.3 parts of honeysuckle, 1.5 parts of scallion, 30 parts of honey, and 600 parts of petals, including lily, osmanthus, acacia, rose, hibiscus, jasmine and day lily, and the petals can be fresh or dried ;

[0025] Step 3: Make the soup stock: in terms of mass components, choose 3 parts of Chinese prickly ash, 3 parts ...

Embodiment 2

[0033] The present invention provides such figure 1 A kind of manufacture craft of braised chicken shown, its manufacture craft is as follows:

[0034] Step 1: Select the main ingredients: select the native chicken from the farm, enter the factory for inspection, then slaughter, depilate, open and eviscerate, and finally tie the whole body of the chicken with holes for later use;

[0035] Step 2: Select auxiliary materials: In terms of mass components, choose 3 parts of amomum, 4 parts of cloves, 1.5 parts of jade fruit, 3 parts of cassia sticks, 4 parts of angelica dahurica, 3 parts of cinnamon, 2 parts of Luo Han Guo, 7 parts of ginger, reed rhizome 3 parts, 2.5 parts of honeysuckle, 2 parts of scallion, 40 parts of honey and 700 parts of petals, the petals include lily, osmanthus japonica, rose, hibiscus, jasmine and daylily, and the petals can be fresh or dried ;

[0036] Step 3: Make soup stock: in terms of mass components, choose 4 parts of peppercorns, 3.5 parts of an...

Embodiment 3

[0044] The present invention provides such figure 1 A kind of manufacture craft of braised chicken shown, its manufacture craft is as follows:

[0045] Step 1: Select the main ingredients: select the native chicken from the farm, enter the factory for inspection, then slaughter, depilate, open and eviscerate, and finally tie the whole body of the chicken with holes for later use;

[0046] Step 2: Select auxiliary materials: In terms of mass components, choose 4 parts of amomum, 5 parts of cloves, 2 parts of jade fruit, 3.5 parts of cassia sticks, 5 parts of angelica dahurica, 4 parts of cinnamon, 2.5 parts of Luo Han Guo, 8 parts of ginger, reed rhizome 4 parts, 2.7 parts of honeysuckle, 2.5 parts of scallion, 50 parts of honey and 800 parts of petals, including lily, osmanthus, rose, hibiscus, jasmine and day lily, and the petals can be fresh or dried ;

[0047] Step 3: Make soup stock: in terms of mass components, choose 5 parts of pepper, 4 parts of aniseed, 3.5 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com