Robot of modular structure and control method of robot

A control method and robot technology, applied in the field of robots, can solve problems such as single structure, cumbersome control methods, and increased difficulty for users to use, and achieve the effects of meeting multi-functional requirements, improving adaptability, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

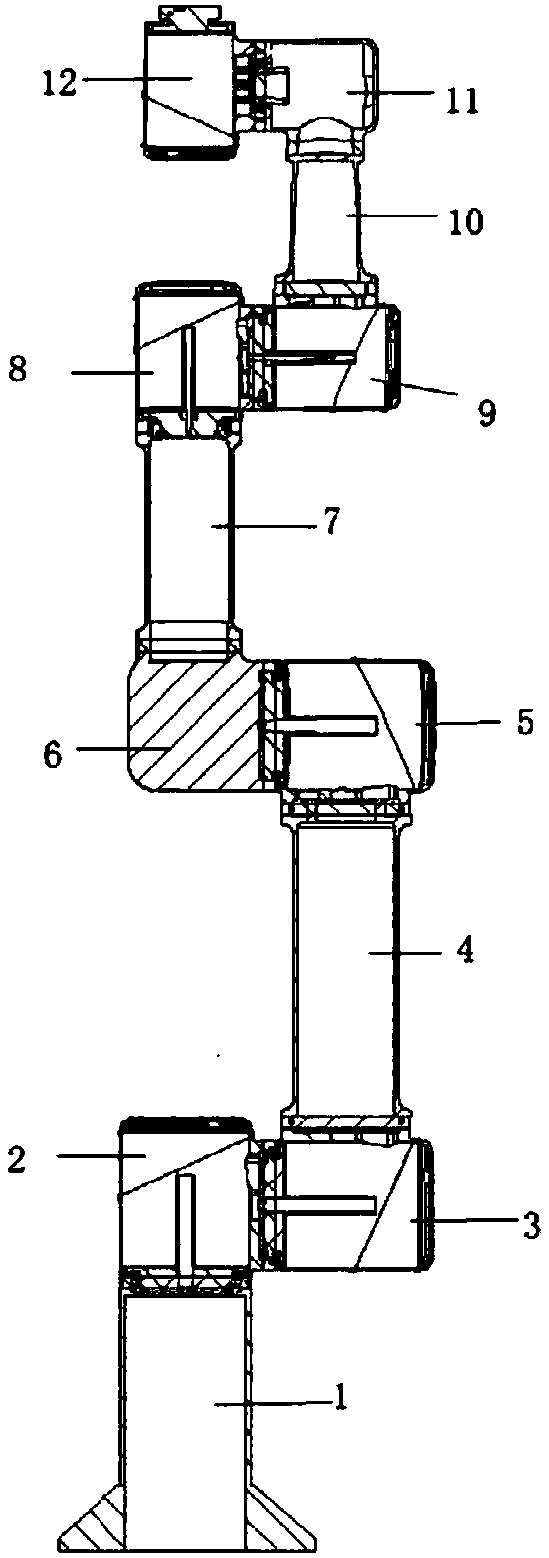

[0046] Such as figure 1As shown, a robot with a modular structure includes a controller and a robot. The robot includes a base, a multifunctional end-effector module, and a hollow joint module and a connection module that are alternately connected between the two. By adjusting the hollow joint module and the connection module to change the degree of freedom and output torque of the robot, the controller is sequentially connected in series with the hollow joint module and the end effector module through a connection line, the connection module is hollow inside, and the connection line runs through the hollow joint module and the connection module;

[0047] The hollow joint module is used to control the connection module or the end effector module to rotate within a range of 360° according to the control information;

[0048] The controller is used to transmit control information to the hollow joint module and the end effector module by using a serial EtherCAT communication meth...

Embodiment 2

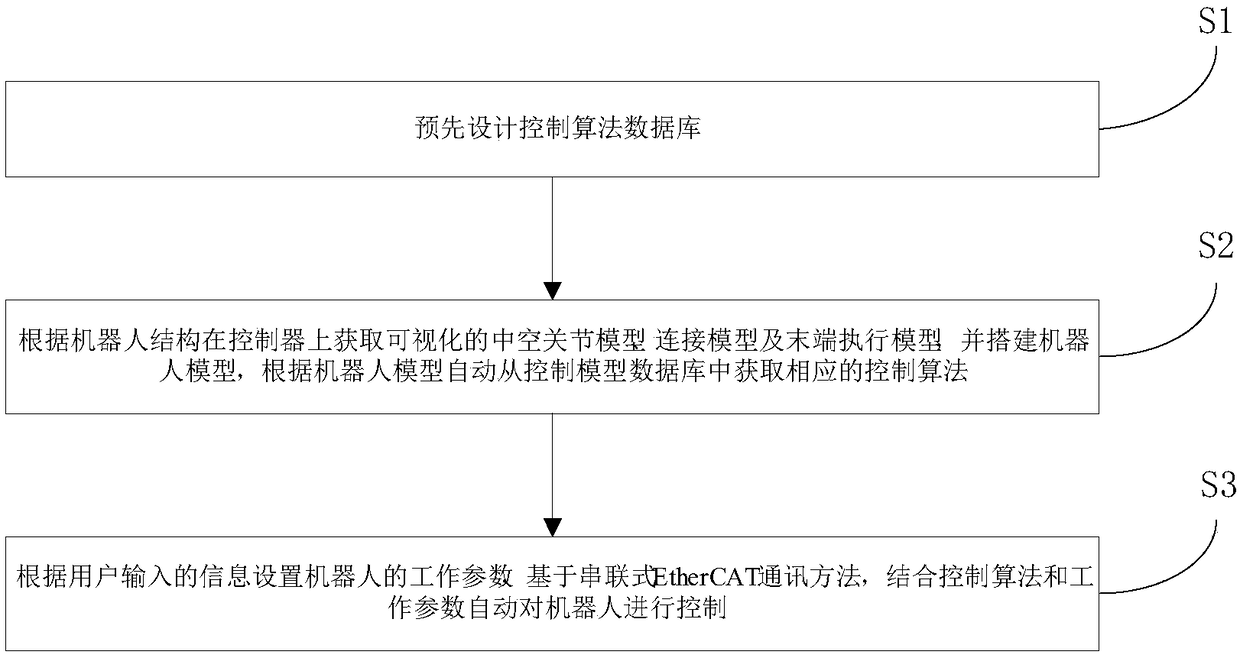

[0070] Such as figure 2 As shown, a control method of a robot with a modular structure comprises the following steps:

[0071] S1. Pre-design the control algorithm database.

[0072] Among them, S1 includes steps S11-S12:

[0073] S11. For each type of robot, calculate the forward and reverse kinematics solution of the robot, and generate a corresponding control algorithm according to the calculated forward and reverse solution. Each type of robot is a different type of robot constructed by an end effector module, a hollow joint module and a connection module. The step of calculating the forward and inverse kinematics solution of the robot is specifically: selecting the corresponding inverse kinematics solution solution method according to the structure and the degree of freedom parameters of the robot to calculate the forward and reverse kinematics solution formula of the robot. Among them, the kinematics inverse solution solution method includes analytical solution metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com