High-strength steel treatment technology

A technology for processing high-strength steel, applied in the field of high-strength steel processing technology, can solve the problems such as the difficulty of direct application of Q-P technology, and achieve the effects of fine grain size, cost reduction and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

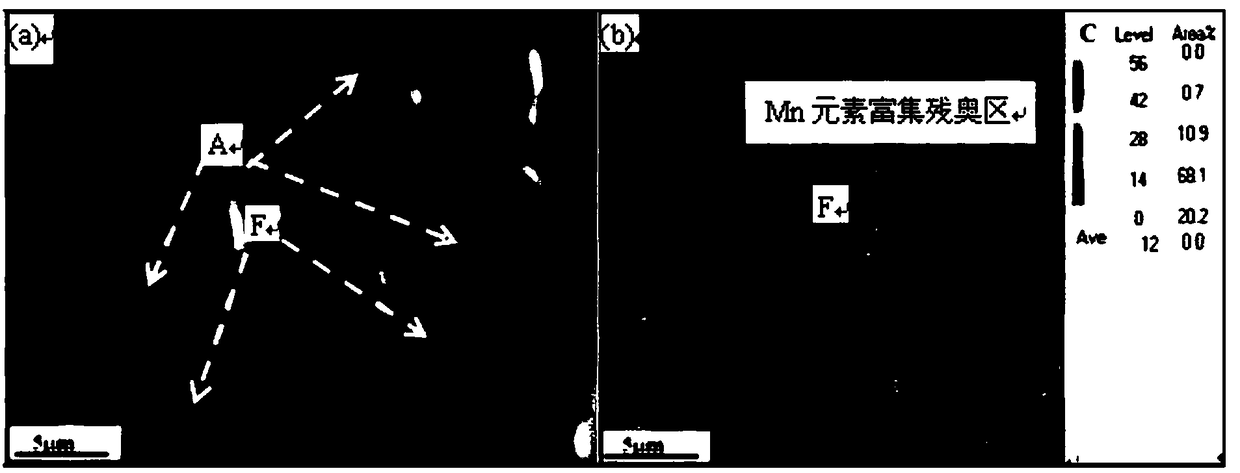

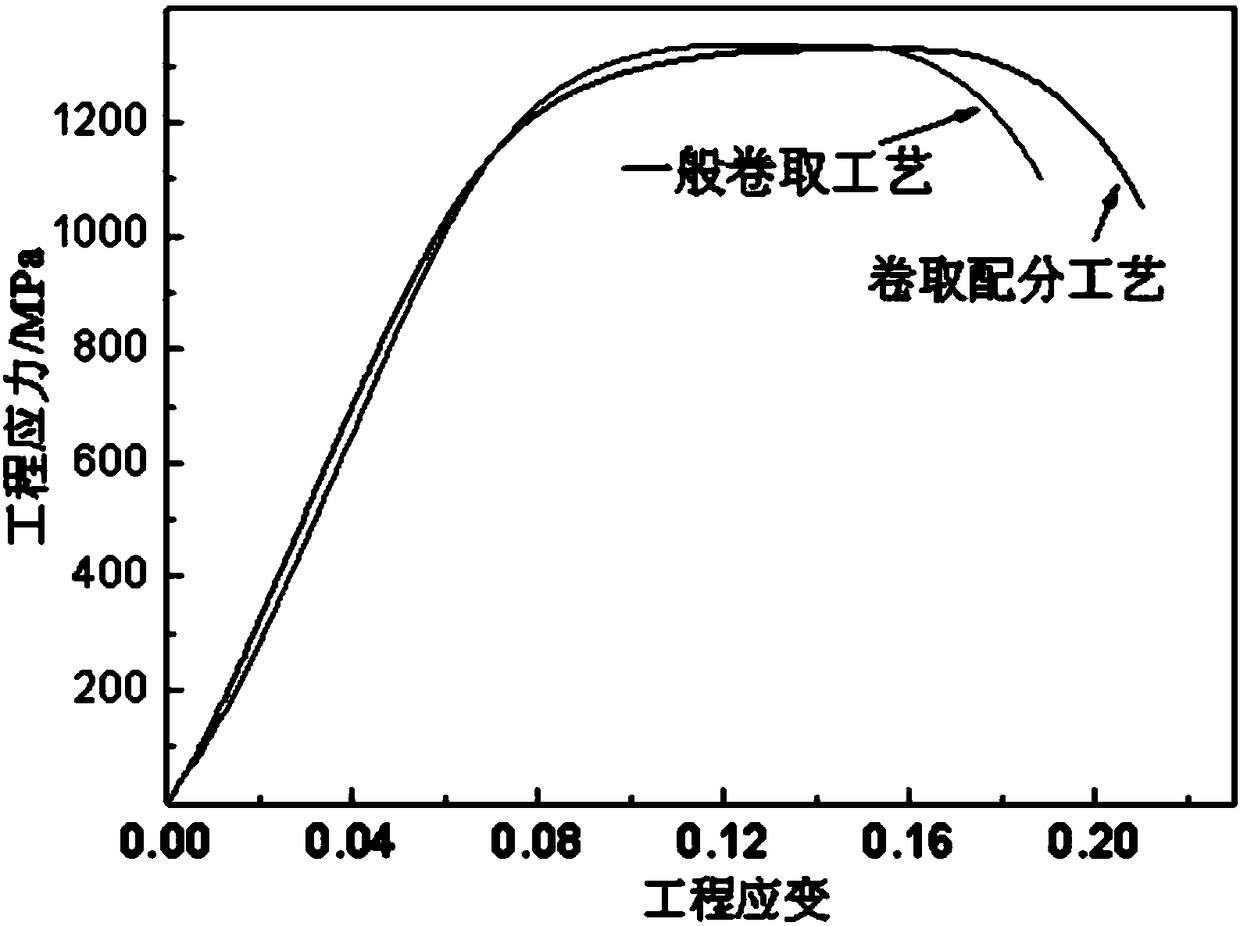

[0025] A high-strength steel treatment process, comprising the steps of:

[0026] Heat the billet to 108°C, the rough rolling pass deformation is 25-45%, the finish rolling total deformation is 50-60%, the final rolling temperature is 840°C, the final rolling plate thickness is 2-5mm, with 50-200 Cooling at a cooling rate of ℃ / s until the coiling temperature is 720-610℃ (660℃), coiling, and then cooling naturally; then cold rolling to 1-2mm, continuous annealing of the cold-rolled plate, the annealing temperature 580-680°C (heating rate: 10-100°C / s), holding time 30s, then air cooling;

[0027] Wherein the billet includes the following percentages of chemical composition: C 0.18-0.22%, Si 1.3-1.8%, Mn 1.3-3.8%, Cu 0.4-0.55%, Ni 0.32-0.4%, P≤0.05%, S≤0.03 %, the balance is Fe and unavoidable impurities.

[0028] The preferred steel slab includes the following percentages of chemical composition: C 0.2%, Si 1.5%, Mn 2.5%, Cu 0.47%, Ni 0.36%, P≤0.05%, S≤0.03%, and the balance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com