Rubber heat-preservation plate

A thermal insulation board and rubber technology, which is applied in thermal insulation, building components, sound insulation, etc., can solve problems such as shortened service life, poor strength, and easy damage, so as to improve sound absorption and noise reduction, shock absorption mechanical strength, and facilitate popularization and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

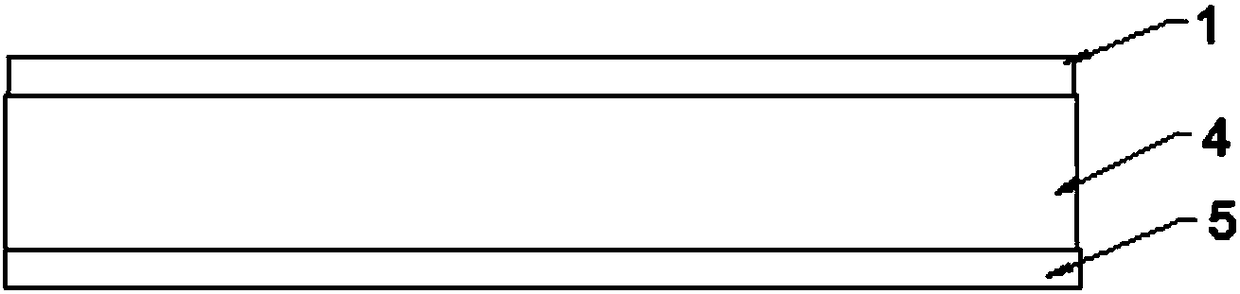

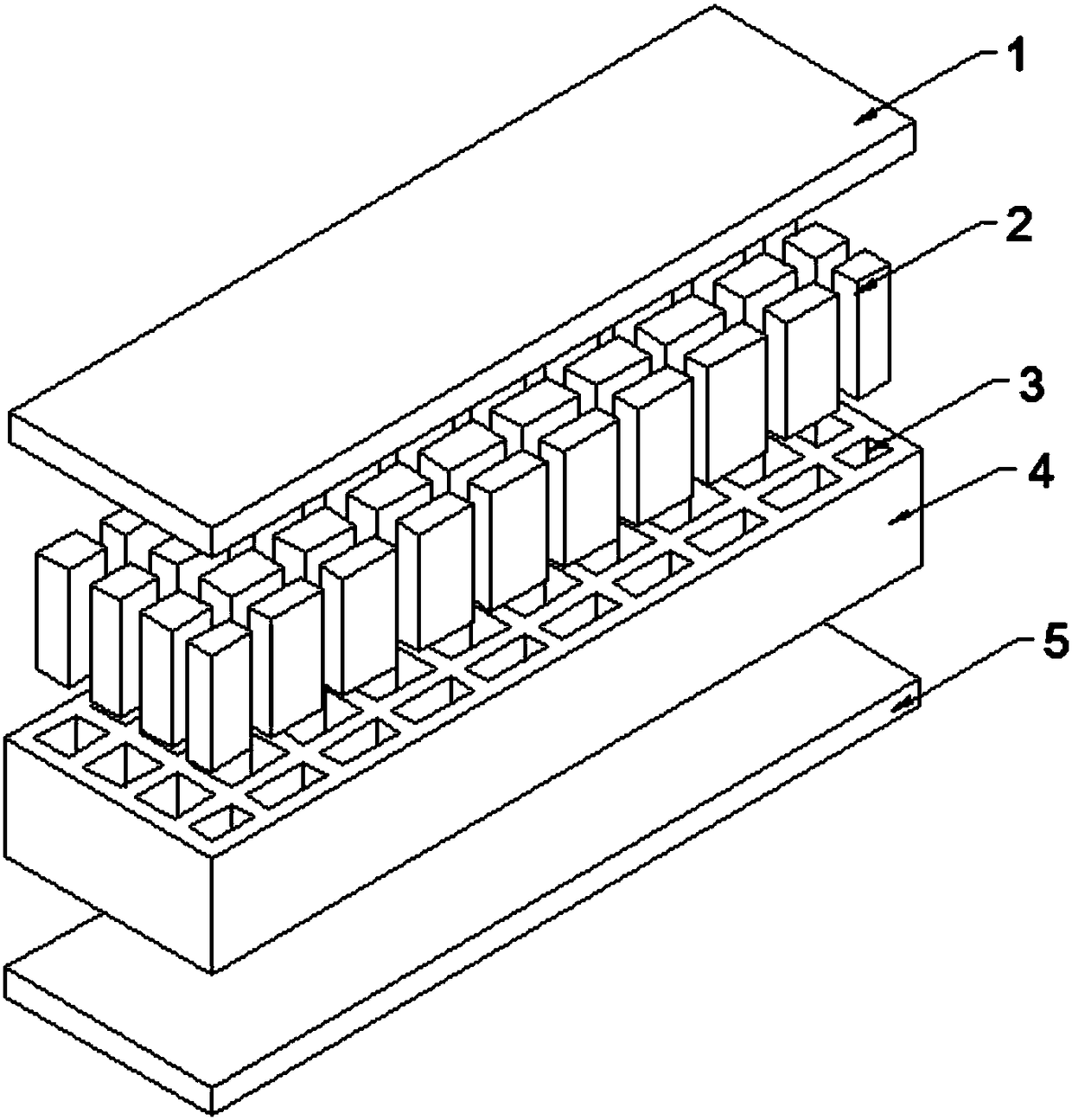

[0016] Such as Figure 1-2 As shown, a rubber insulation board includes a top layer 1, a middle layer 4 and a bottom layer 5 fixedly connected sequentially from top to bottom. The top layer 1 and the bottom layer 5 are planar structures, and the purpose of designing the top layer 1 and the bottom layer 5 as a flat structure is to better package and fix the middle layer 4 to form an organic whole. The top layer 1 is a thermoplastic polyurethane engineering plastic board, and the purpose of designing the top layer 1 as a thermoplastic polyurethane engineering plastic board is to improve the mechanical strength of the top layer 1 .

[0017] The bottom layer 5 includes an organic fiber material at the center and an organic packaging board wrapped on the outside of the organic fiber material. The bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com