Micro-miniature turbine engine shaft sleeve

A turbine engine, micro-miniature technology, applied in the direction of engine components, engine lubrication, machine/engine, etc., can solve the problems of increasing the use and maintenance cost of micro-turbine engines, affecting the service life of the engine, and insufficient cooling of bearing components, etc., to achieve simplification The effect of complex oil circuit design, increased life, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

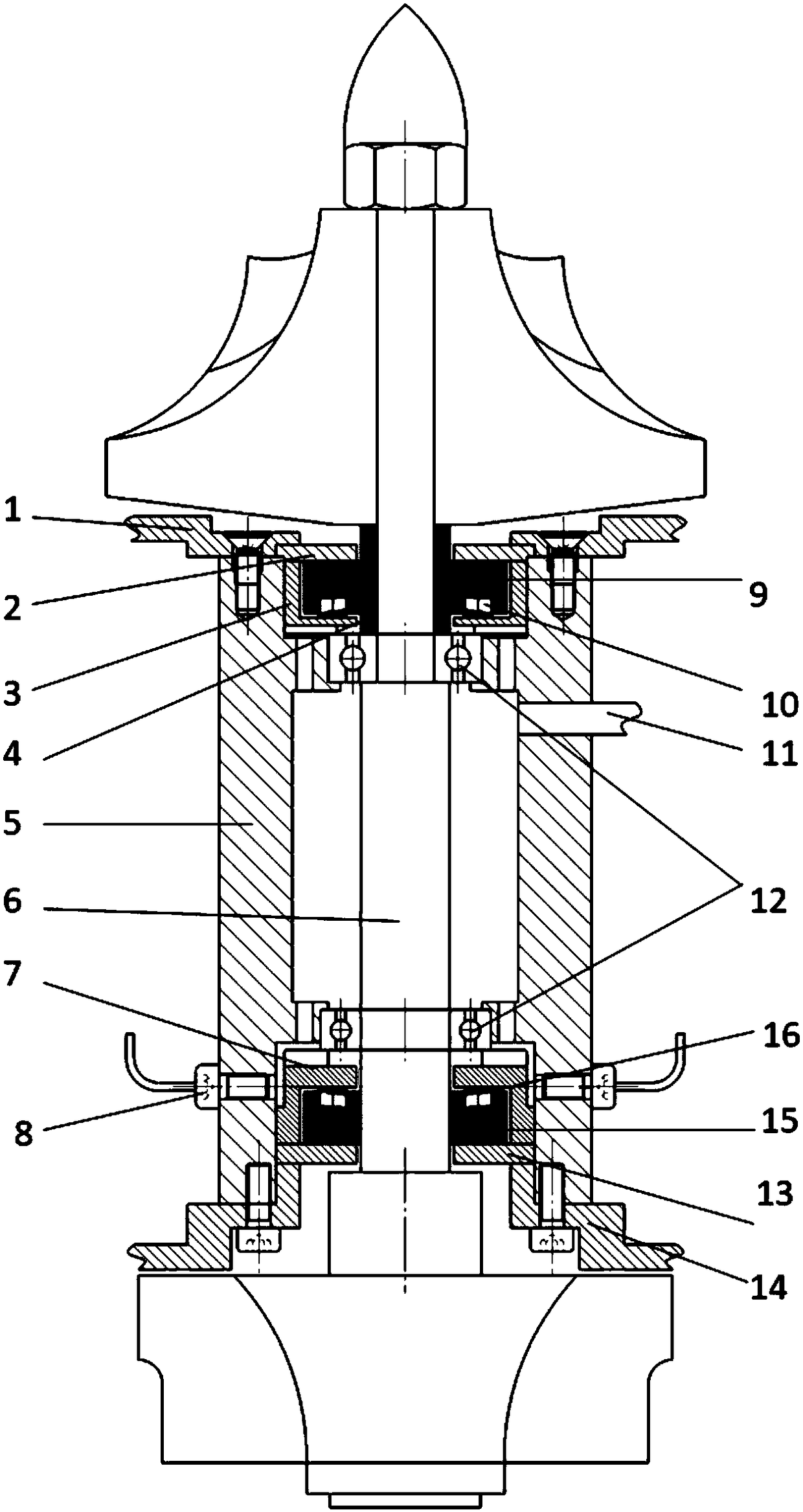

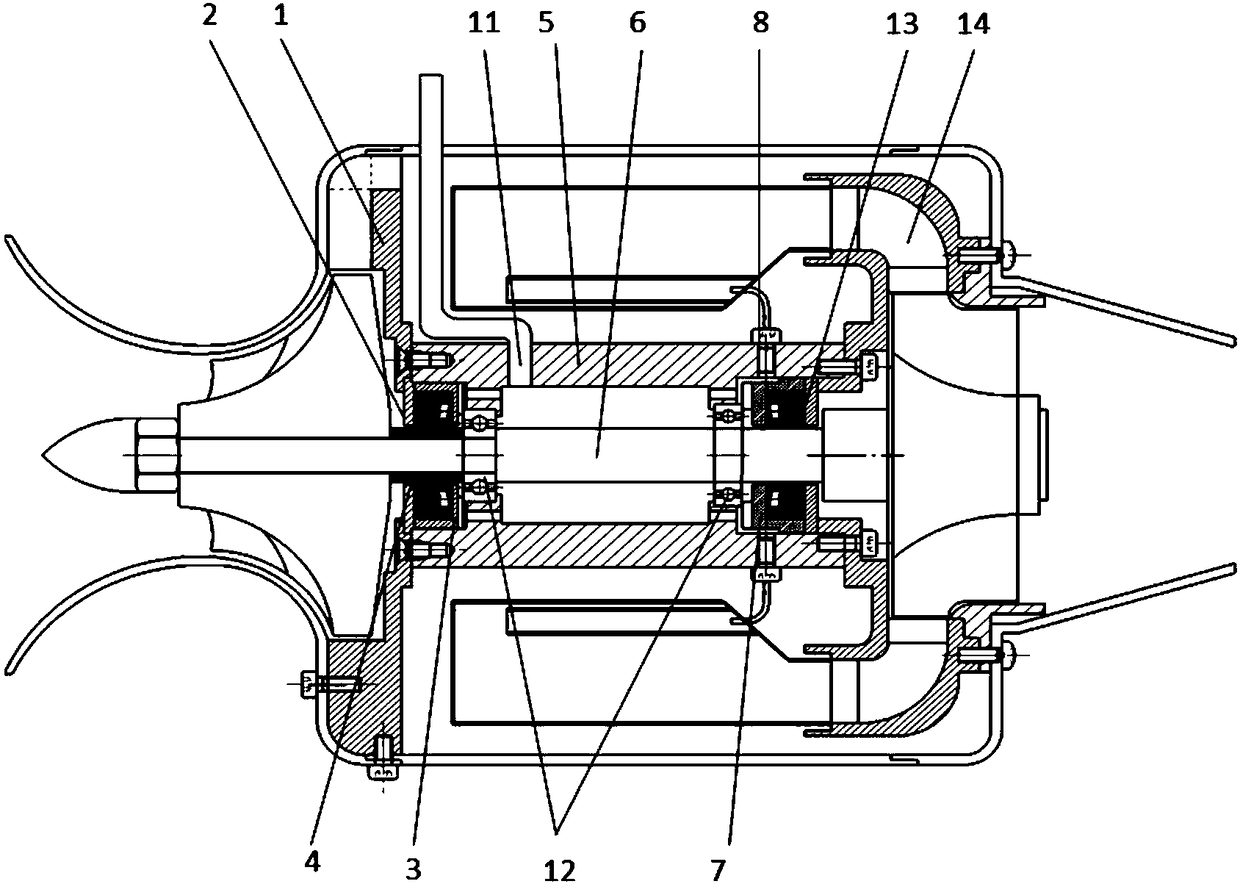

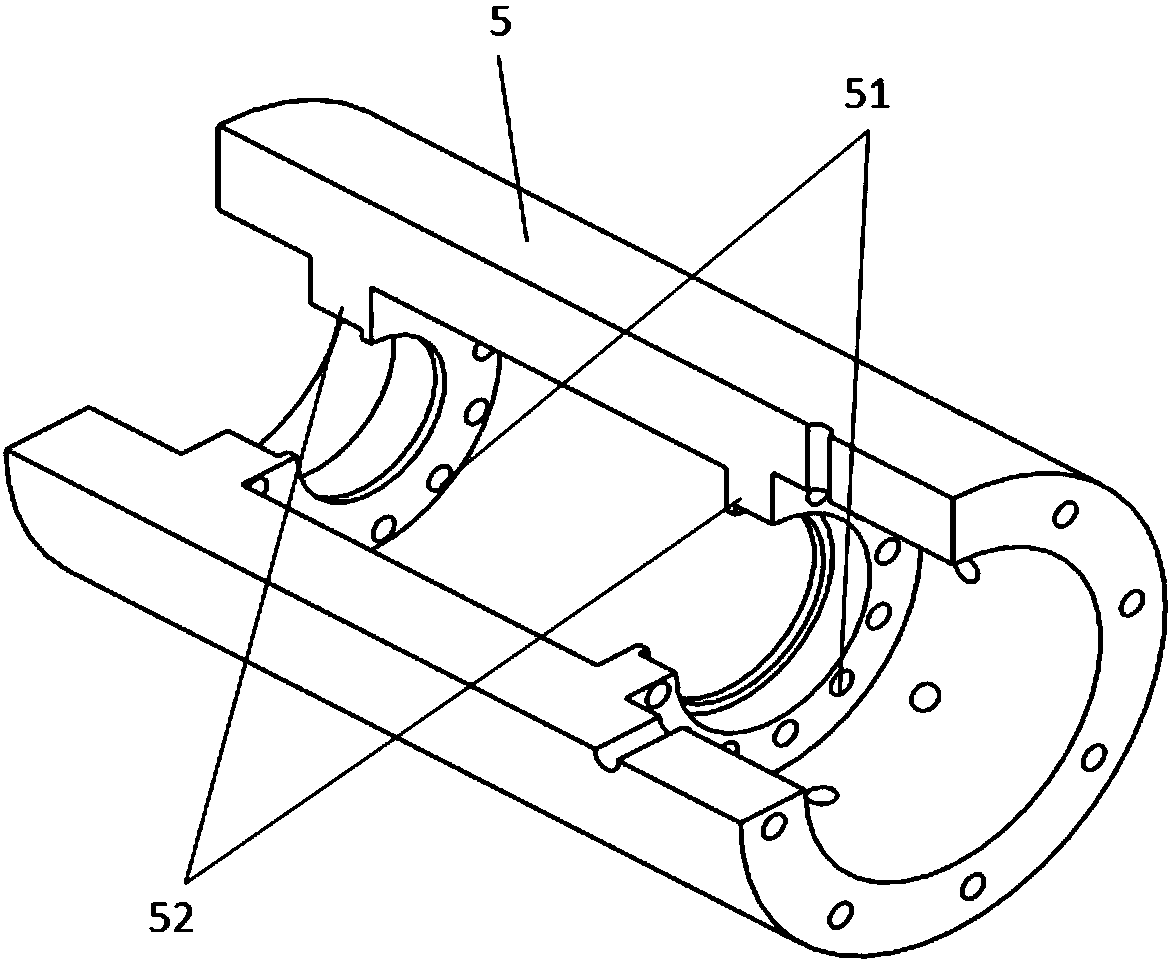

[0022] Such as Figures 1 to 7 As shown, the bushing of a micro turbine engine is characterized in that it includes a bushing housing 5 installed on the shaft 6 through a bearing 12, the front end of the bushing housing 5 is connected with the diffuser 1, and the bushing shell The shaft 6 outside the front end bearing 12 of the body 5 is provided with a front carbon ring 9, the front carbon ring 9 is installed on the sleeve 4 of the shaft 6 through the front baffle plate 2 and the front carbon ring outer cover 3, and the rear end of the shaft sleeve housing 5 is connected to the The turbine guide 14 is connected, and the shaft 6 outside the rear end bearing 12 of the shaft sleeve housing 5 is provided with a rear ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com