100KW-level high-pressure plunger pump with self-cleaning function

A high-pressure plunger pump, self-cleaning technology, applied to the parts of the pumping device for elastic fluid, pump components, variable displacement pump parts, etc. Sealing effect and other issues, to achieve the effect of achieving lubrication, prolonging service life, avoiding oil seal failure and air entry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

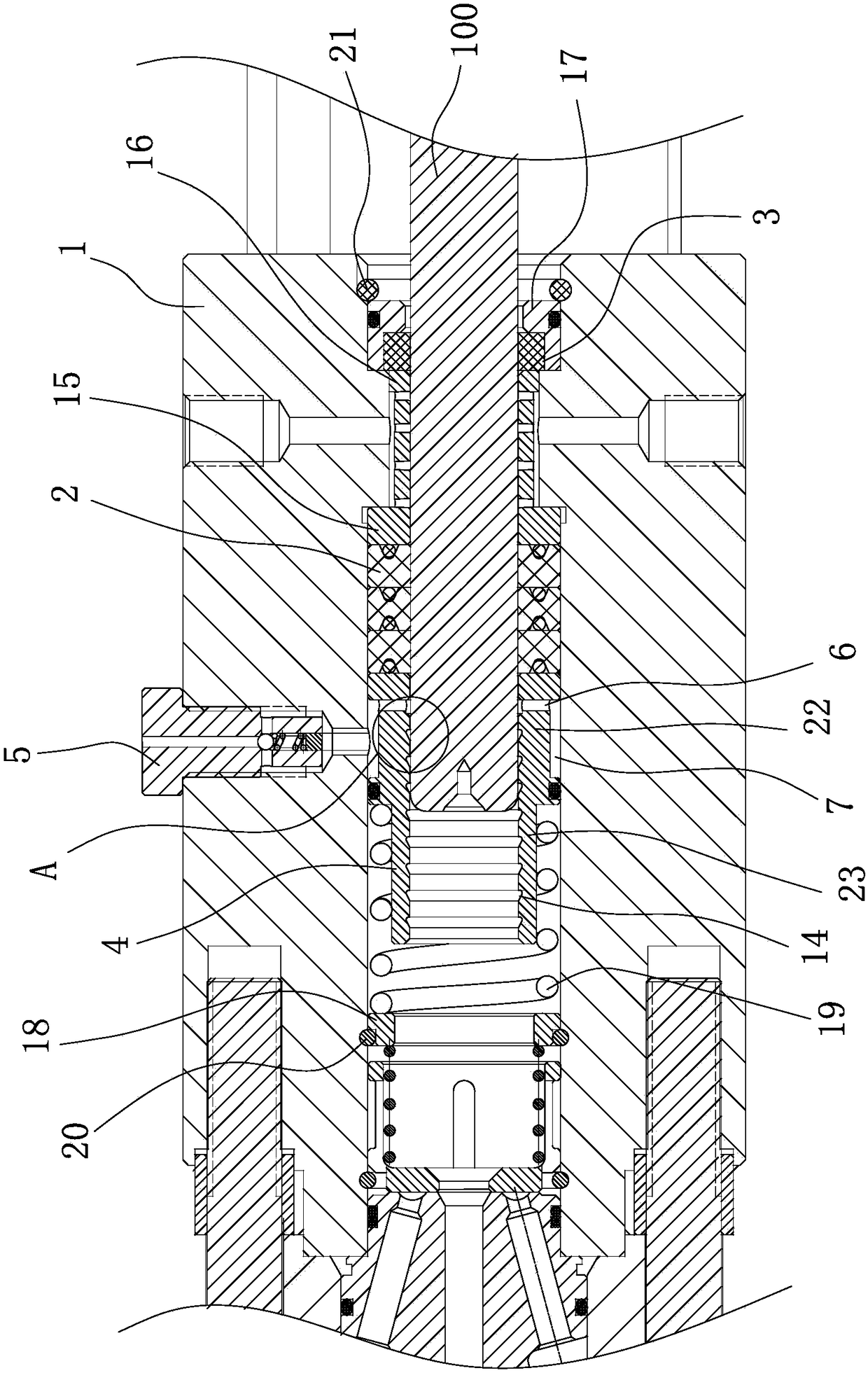

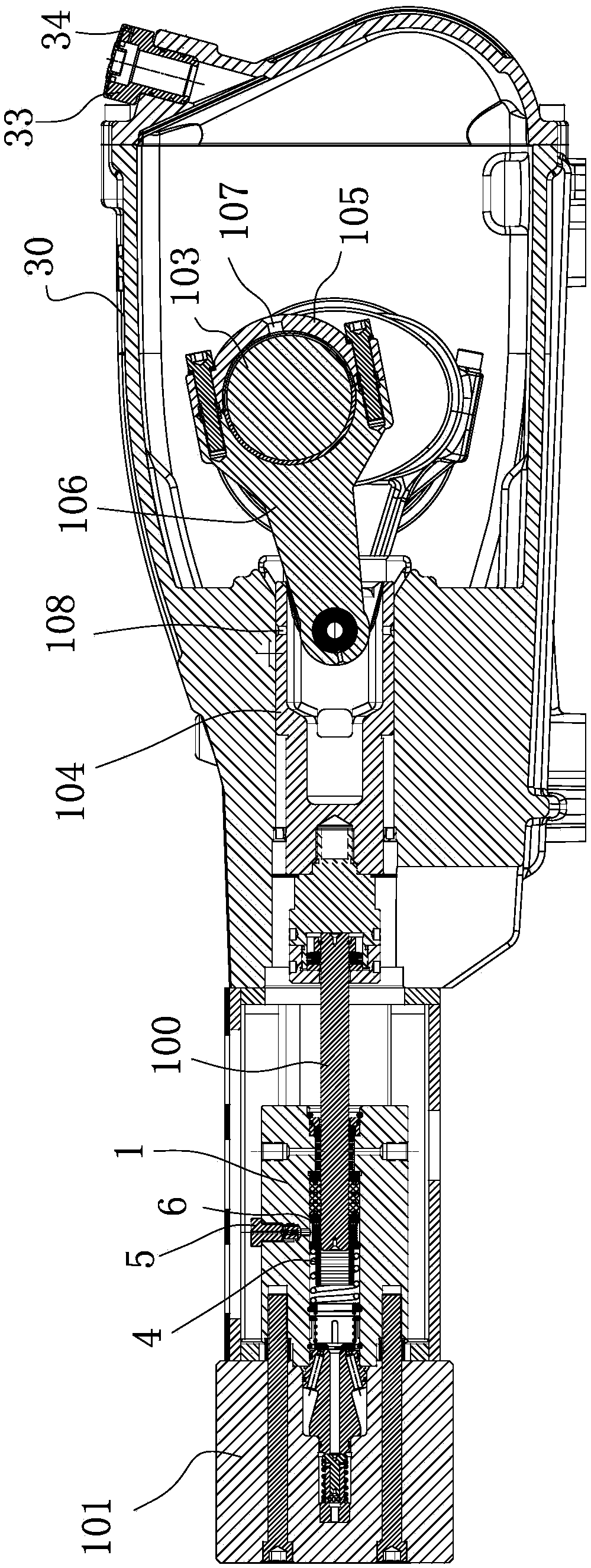

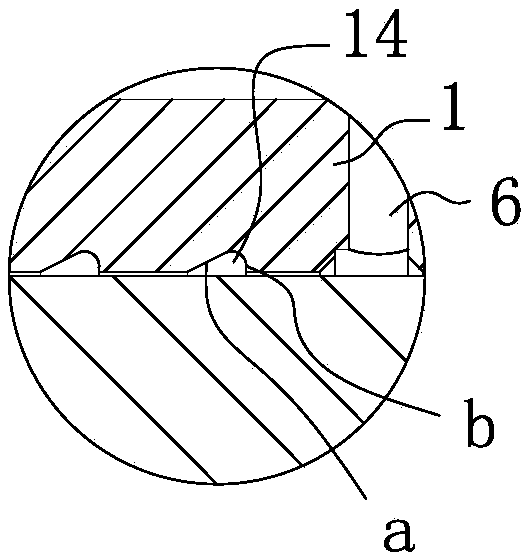

[0030] Such as figure 1 with figure 2 As shown, a 100KW high-pressure plunger pump with self-cleaning function includes a pump head 101 and a crankcase 30, a stuffing box 1 is provided between the pump head 101 and the crankcase 30, and a crankcase 30 is provided with The crankshaft 103, the crankshaft 103 is connected to the plunger 100 through the crosshead 104, the plunger 100 is inserted into the stuffing box 1, the stuffing box 1 is provided with the main water seal 2 and the auxiliary water seal 3, and the stuffing box 1 is also provided with There is a retaining ring 4, the retaining ring 4 is located at the end of the main water seal 2 away from the auxiliary water seal 3 and the retaining ring 4 is in sealing connection with the stuffing box 1, it is characterized in that the retaining ring 4 is in clearance fit with the plunger, The stuffing box 1 is provided with a clear water check valve 5 , and the retaining ring 4 is provided with a clear water channel 6 penetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com