Multi-cycle variable-flow heat pump system

A heat pump system, variable flow technology, applied in the direction of fluid circulation arrangements, compressors with reversible circulation, lighting and heating equipment, etc., can solve the problems of large temperature fluctuations, high operating costs, and inability to change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with specific embodiments.

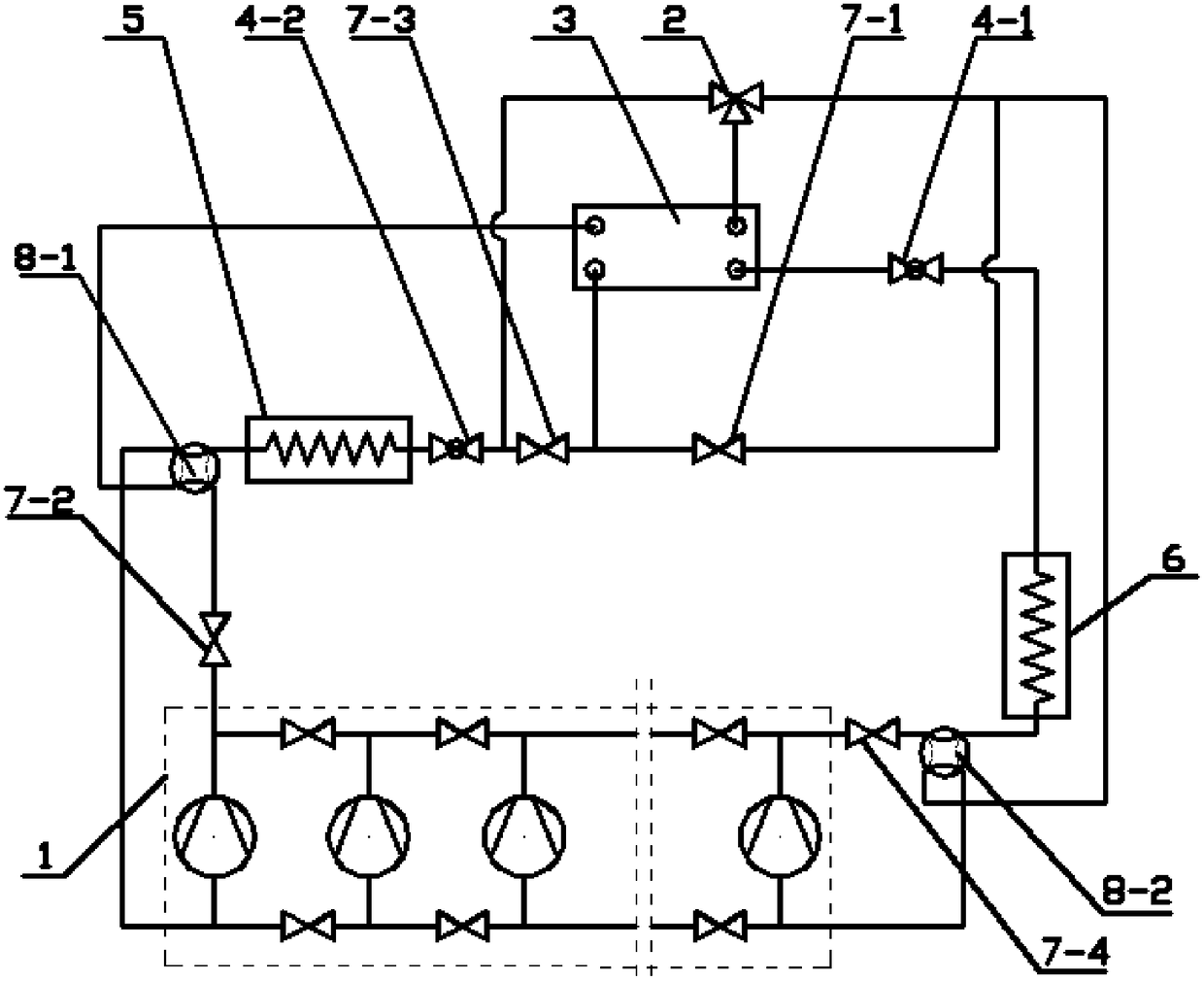

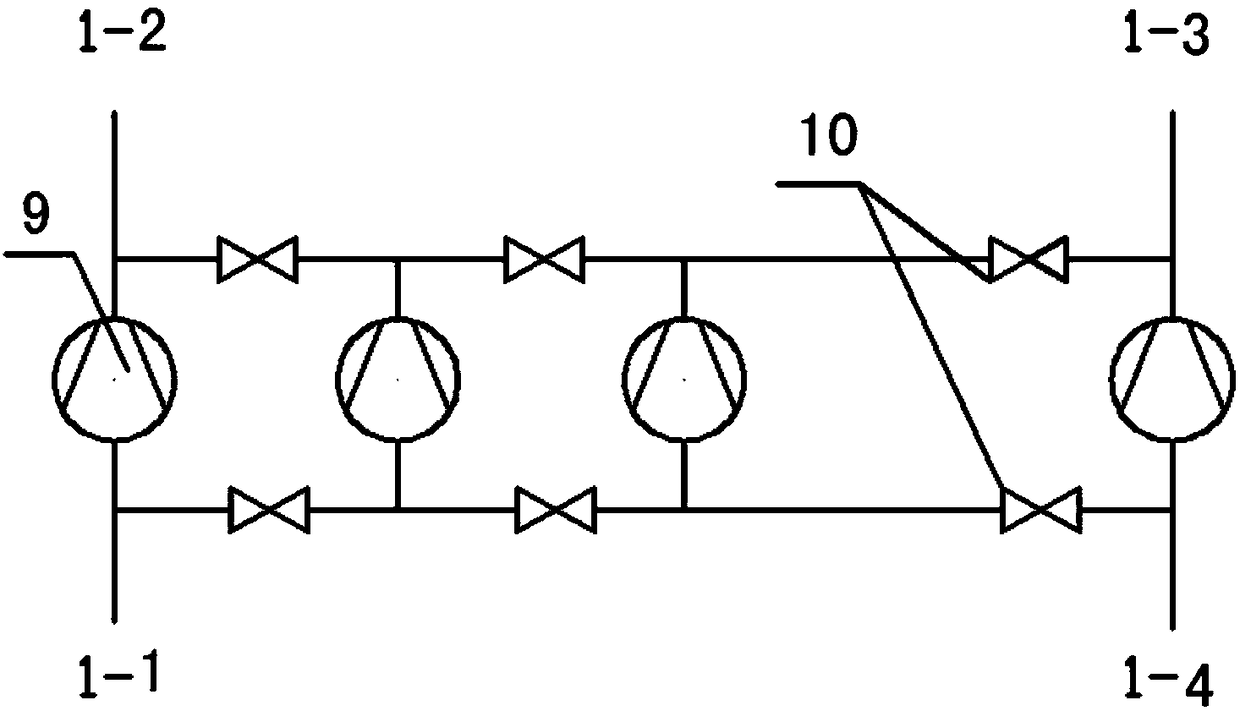

[0028] The schematic diagram of the multi-cycle variable flow heat pump system of the present invention is as follows Figure 1-Figure 2 As shown, it includes refrigeration compressor unit 1, three-way valve 2, heat exchanger 3, indoor unit 5, outdoor unit 6, first throttle valve 4-1, second throttle valve 4-2, first four-way switch Directional valve 8-1, the second four-way reversing valve 8-2, the first valve 7-1, the second valve 7-2, the third valve 7-3 and the fourth valve 7-4. The refrigeration compressor unit 1 includes a plurality of compressors 9, each of which is divided into a first exhaust port 1-2 and a second exhaust port 1-3 after the exhaust end of each compressor 9 is connected in parallel. After the suction ends of the compressors 9 are connected in parallel, they are divided into a first suction interface 1-1 and a second suction interface 1-4, between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com