Matrix type visual detection system and method for detecting defect of transparent material

A transparent material and visual inspection technology, which is applied in the analysis of materials, material analysis through optical means, and measurement devices, etc., can solve the problems of quality classification accuracy and precision limitation, limited fixed acquisition angle, and limited imaging data, etc. , to achieve the effect of improving the accurate detection rate, improving the accurate classification and grading, and increasing the scanning frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

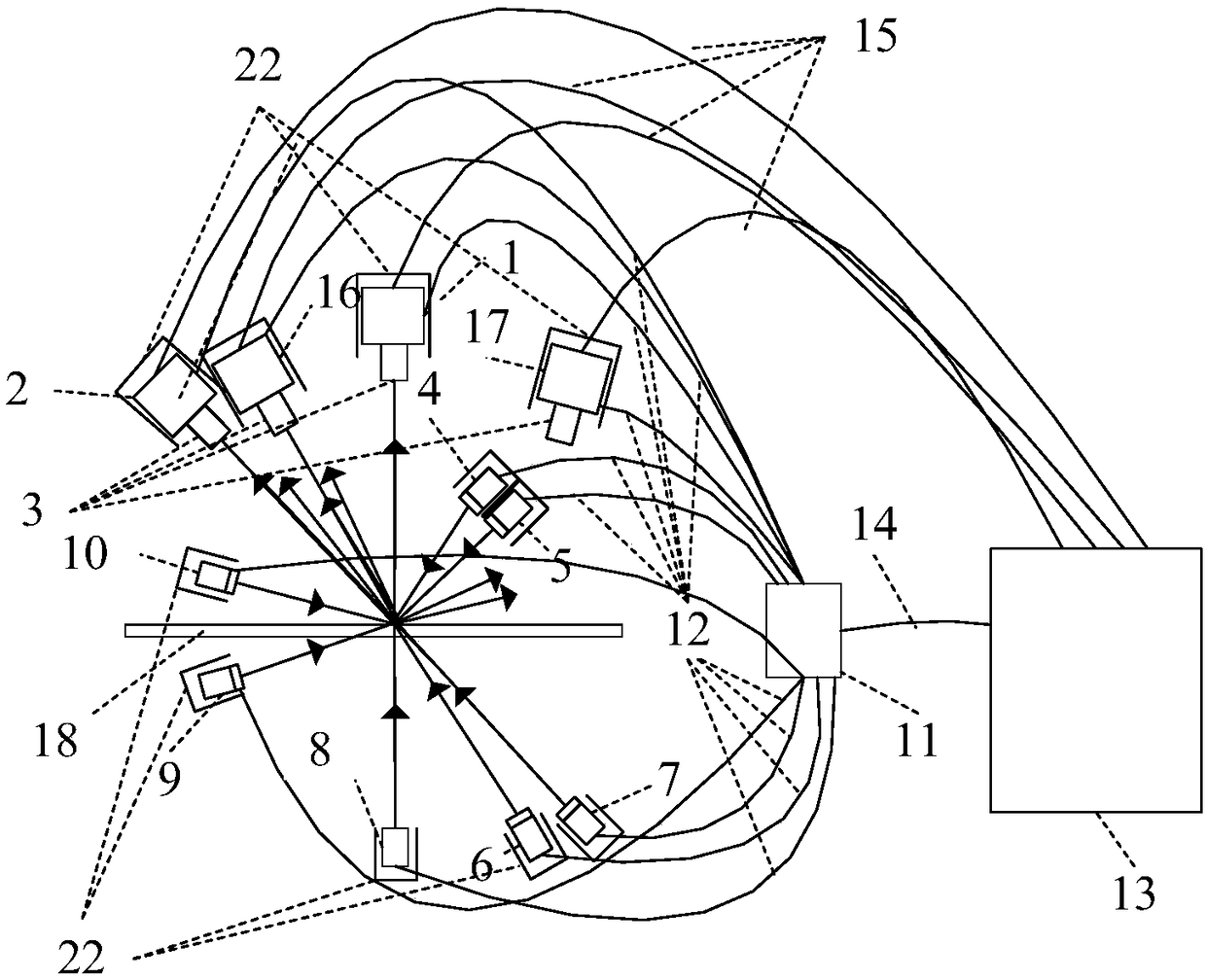

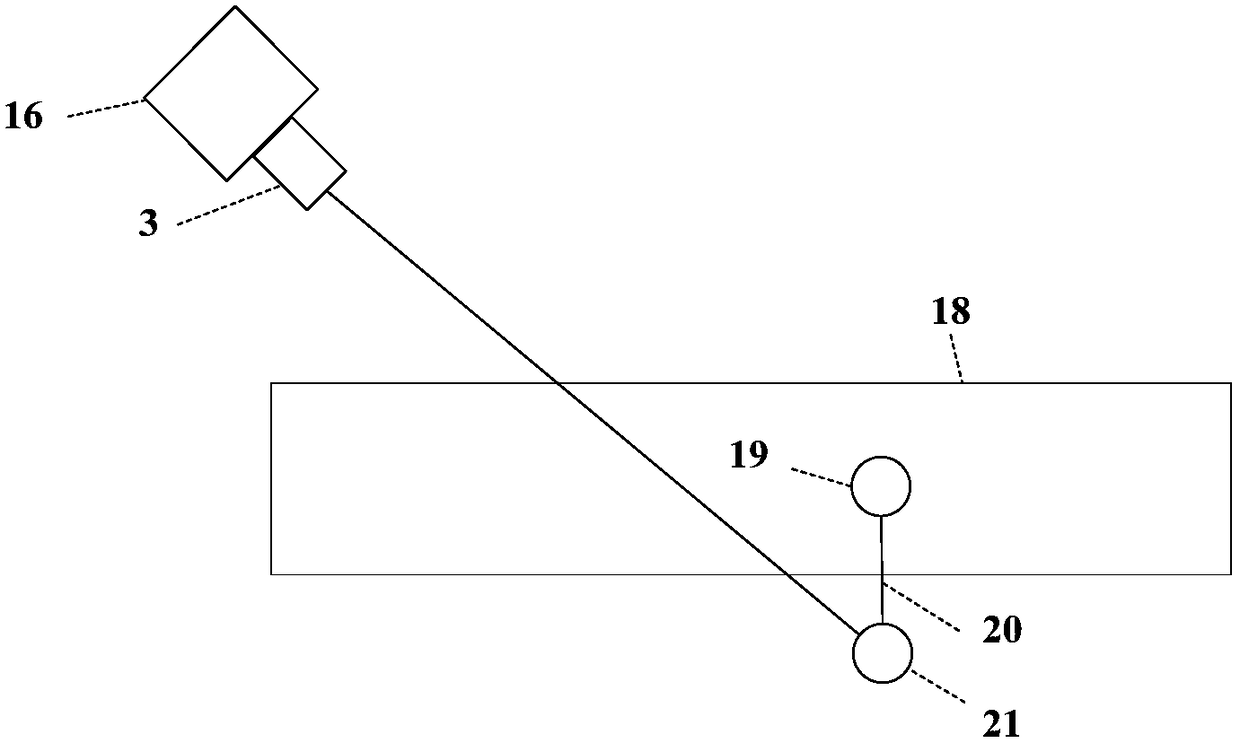

[0061] The present invention provides a matrix visual inspection system for defect detection of transparent materials, which is used for matrix image detection of surface and / or internal defects of transparent materials under different lighting modes. The visual inspection system of this embodiment uses the imaging matrix Capture multi-channel images of the surface and / or internal defects of transparent materials under different illumination modes, and by adding imaging matrix and illumination matrix, perform imaging scanning on transparent materials from multiple angles, and capture defects on the surface and / or internal defects of transparent materials from multiple angles Image, obtain multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com