Method for measuring milk curd drainage shrinkage

A technology of milk curdling and water separation, applied in the food field, can solve the problems of insufficient result accuracy, poor repeatability, and difficulty in repeating, and achieve the effect of improving operability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

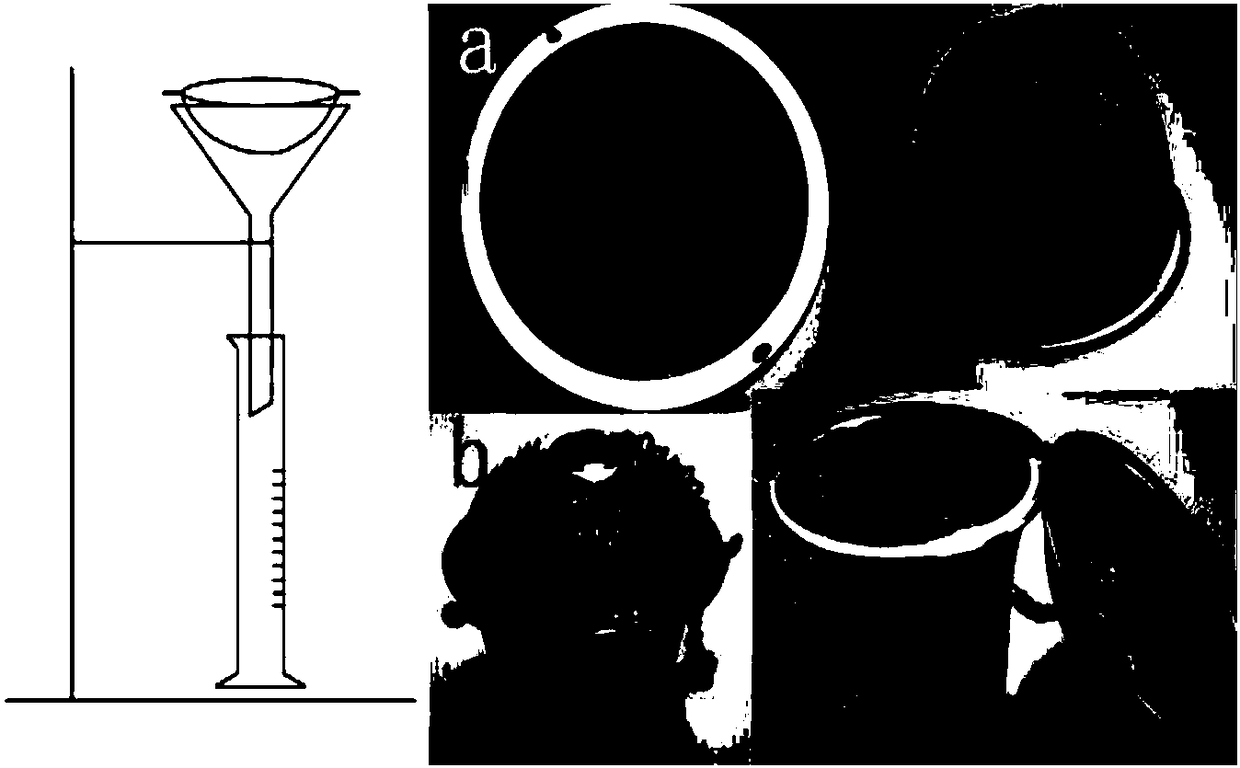

[0043] The special device for the method for measuring the water shrinkage of curd provided by the present invention, its structural schematic diagram is as follows figure 1 As shown; the device consists of an iron stand, a funnel and a leaky net; the leaky net is nested in the funnel; the funnel is fixed on the iron stand, and the funnel is a short-necked glass funnel with a mouth diameter of 90mm and a pipe diameter of 9mm; the leaky net is the inner diameter 85mm stainless steel leaking screen.

Embodiment 2

[0045] 1. Preparation of curd to be tested:

[0046] After the raw milk is uniformly pasteurized, weigh 30ml each and place it in a 100mL small beaker with uniform specifications, add 0, 0.02%, 0.04% calcium chloride aqueous solution with a mass percentage concentration of 1% respectively, each concentration There are 6 samples. After uniform heating to 30°C, 0.005% rennet was added, and the milk was curd for 30 minutes to obtain the curd to be tested. and repeated the experiment 3 times.

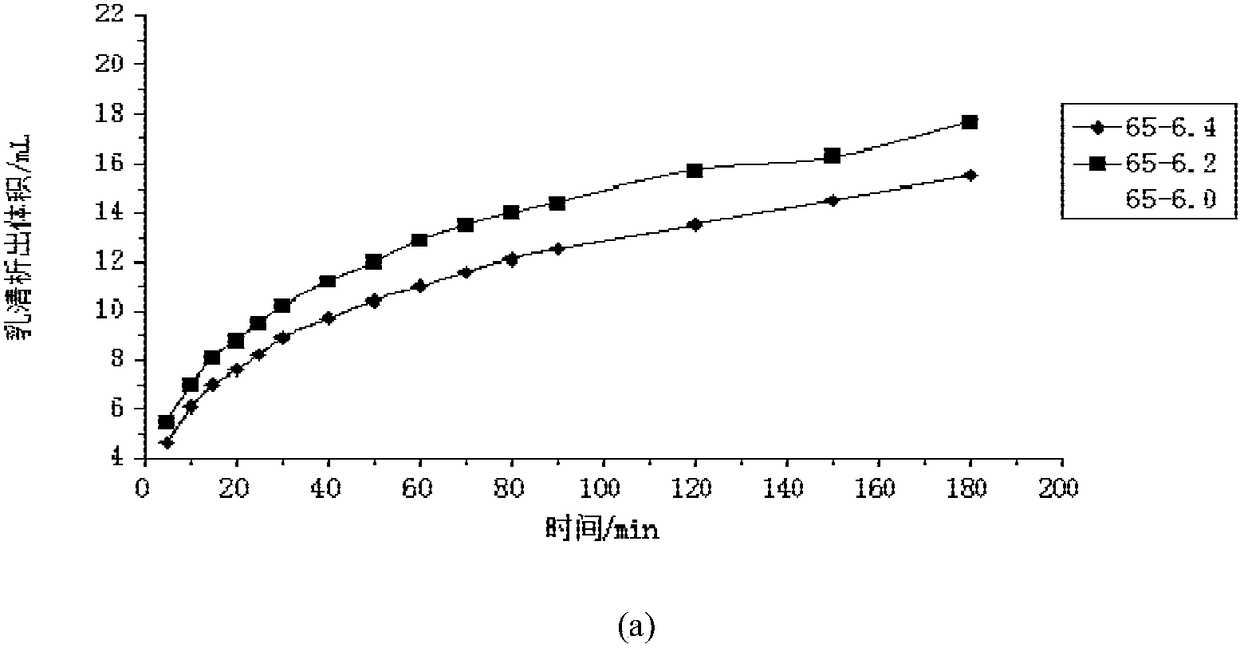

[0047] 2. Determination of the water shrinkage characteristics of the curd to be tested:

[0048] The curd to be tested is transferred to the device provided in Example 1, and the timing is started, and the volume of whey separated out is recorded every 5 minutes until 3 hours.

[0049] Calculate the hydrolysis shrinkage rate constant k of whey according to formula 1.

[0050] V=V ∞ ×(1-e -kt ) Formula I

[0051] In formula I, V is the whey volume separated out at time t, and the uni...

Embodiment 3

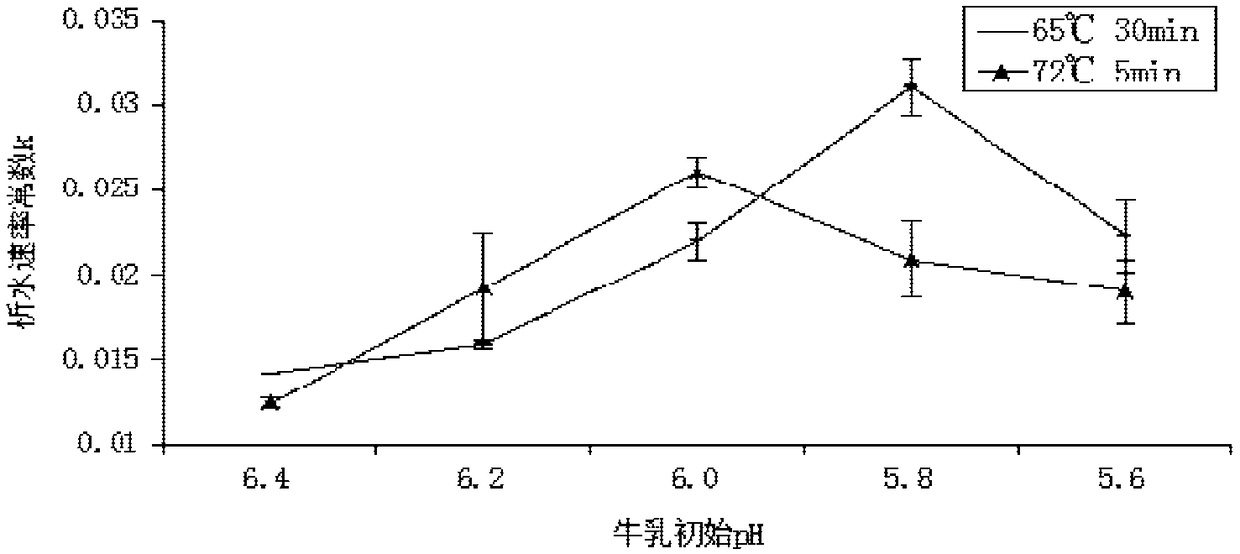

[0080] Example 3, Evaluation of water-separation shrinkage of curd milk (influence of different sterilization treatments and pH of raw milk on water-separation shrinkability of curd milk)

[0081] Sterilize the raw milk at 65°C for 30 minutes and 72°C for 5 minutes, adjust the pH of the milk to 6.4 after cooling, and enzymatically curd the milk for 30 minutes to obtain the curd to be tested.

[0082] The curd to be tested is transferred to the device for measuring the water-separation shrinkage of the curd provided in Example 1 of the present invention, and the volume of whey in the curd to be measured is separated out from the funnel within the time t (3h) is recorded, Denote it as V; according to V and time t, formula I is obtained by fitting, that is, the water separation shrinkage rate constant k of the curd to be measured in 3h is obtained by formula I;

[0083] V=V ∞ ×(1-e -kt ) Formula I

[0084] In the formula I, V is the whey volume separated out in the curd to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com