Device for treating organic waste liquid in spherical nuclear fuel element production line

A nuclear fuel element and waste liquid treatment technology, which is applied in nuclear engineering, radioactive purification, etc., can solve the problems of unsatisfactory waste liquid and production interruption, and achieve the effects of simple process flow, reduced consumption, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

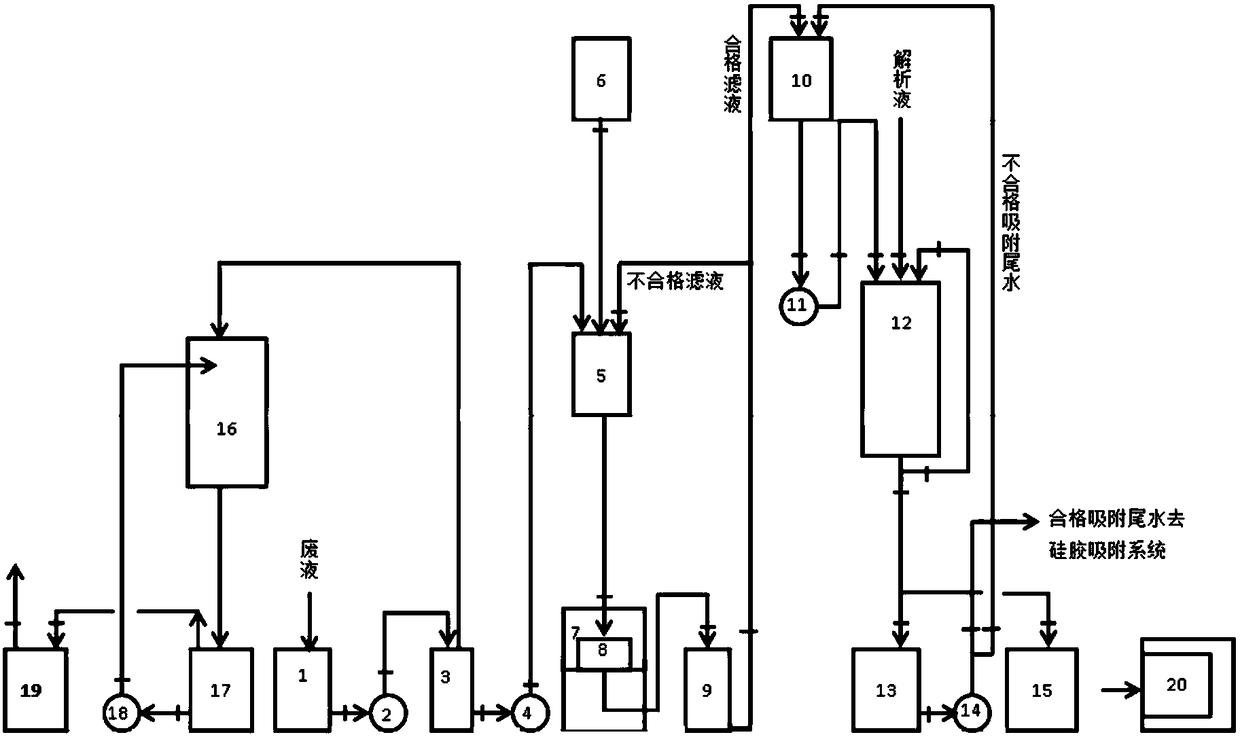

[0028] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] Such as figure 1 As shown, a spherical nuclear fuel element production line of the present invention contains an organic waste liquid treatment device, which includes a waste liquid storage tank 1, a waste liquid supply system connected to the inlet of the waste liquid storage tank 1, and an outlet of the waste liquid storage tank 1 The connected ammonia recovery system, flocculation filtration system, and activated carbon adsorption system; the ammonia recovery system, flocculation filtration system, and activated carbon adsorption system are connected by stainless steel pipes;

[0030] The ammonia distillation recovery system comprises an ammonia distillation tank 3, a magnetic pump 2 4, a falling film absorption tower 16, an absorption liquid storage tank 17, a centrifugal pump 5 18, and a water injection u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com