Composite connection method for radiator type products

A composite connection and radiator technology, which is applied in the field of welding, can solve the problems of poor sealing of the radiator cavity and high requirements for friction stir welding tooling, so as to prevent volatilization and melting out of heat, reduce tooling requirements, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

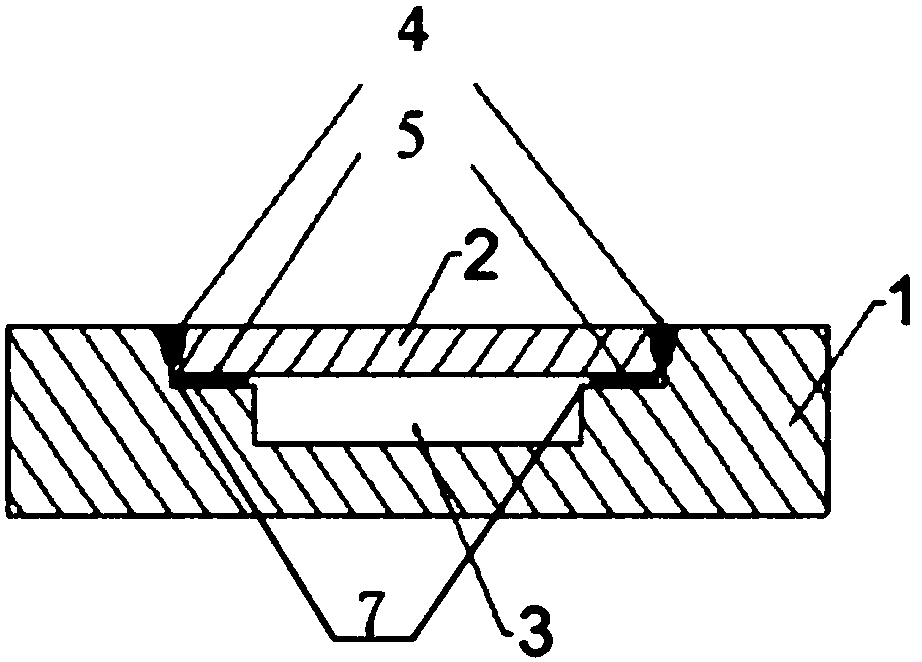

[0047] refer to figure 1 , figure 1 It is a schematic diagram of the friction stir welding and glued compound connection joint of the radiator of the present invention; this figure is a cross section of part of the water channel of the water-cooled radiator. The method of this embodiment is completed by the following steps: Step 1: Process the water-cooled radiator into the form of a base plate and a cover plate, process the base plate 1 into a process step 7, and clean the weld position; Step 2: Coat the metal with a synthetic adhesive On the process step 7 of the whole welding seam, cover the cover plate and apply a certain pressure to make the glue solidify, and the cover plate 2 and the base plate 1 are firmly adhered; Step 3: Perform friction stirring on the docking surface of the base plate 1 and the cover plate 2 Welding, to complete the sealing welding of the waterway welds, to form a composite weld of friction stir welding and adhesive bonding.

Embodiment 2

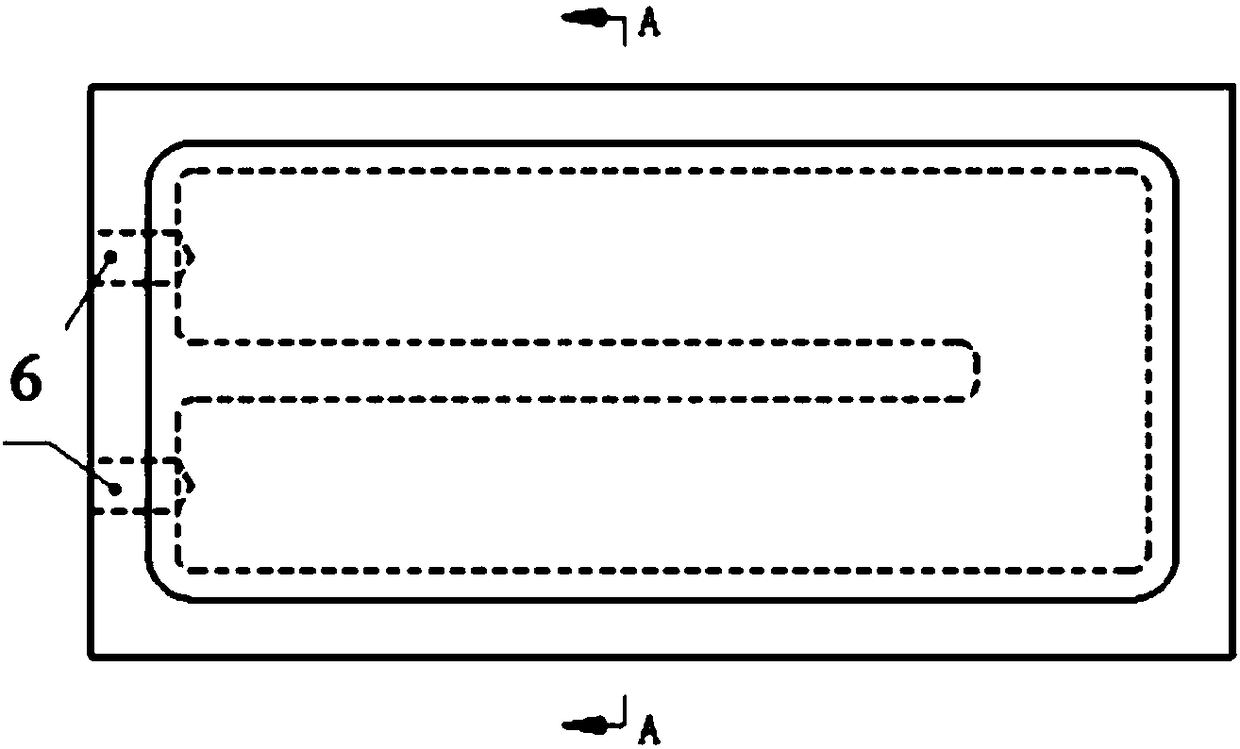

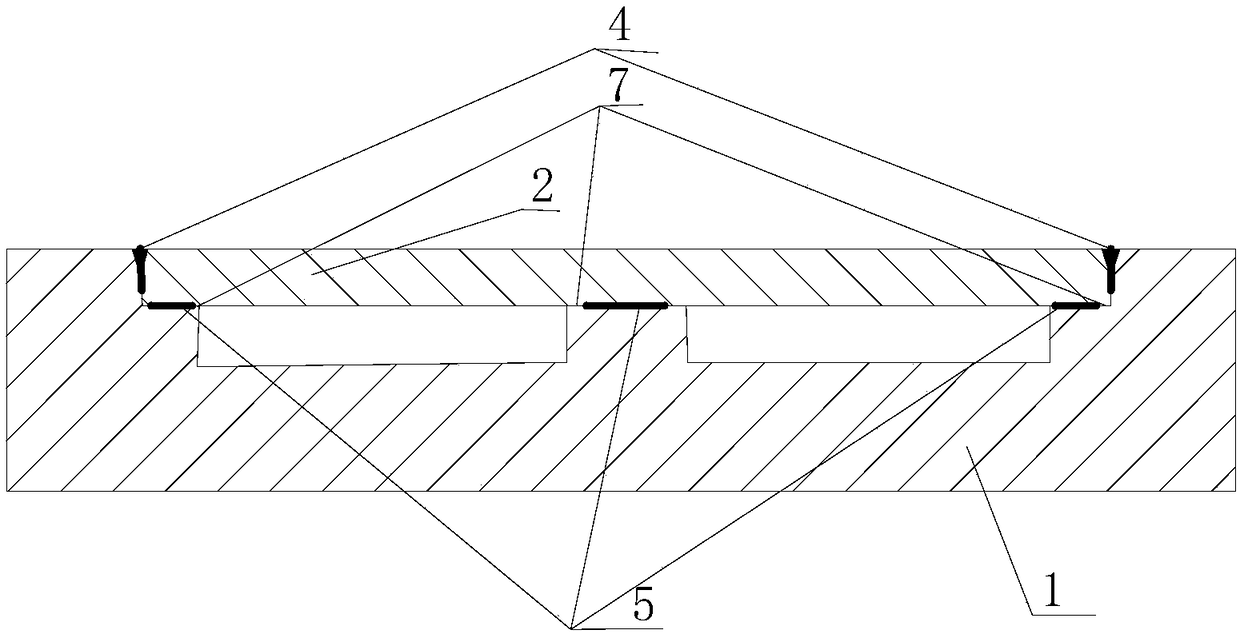

[0049] refer to figure 2 and image 3 , figure 2 It is a schematic diagram of friction stir welding and glue joint composite connection of U-shaped circulating water radiator, image 3 yes figure 2 Sectional view of plane A-A in the center; figure 2 In the process, the circulating water enters the U-shaped circulating water channel through the water inlet 6; because of the narrow width of the abutment, it is impossible to process a process step of sufficient width for friction stir welding. Because the joint strength requirement of the internal abutment and the cover plate is not high, it has no essential influence on the sealing of the product, so the weld between the abutment and the cover plate can be used as an internal weld seam, and only glued for connection, as shown in the figure As shown in 3, the bonding part 5 is formed, which can guide the flow direction of the liquid in the water channel and prevent the flow between the steps of the water channel and the c...

Embodiment 3

[0051] refer to Figure 4 and Figure 5 , Figure 4 It is a schematic diagram of friction stir welding and adhesive bonding composite connection of serpentine circulating water radiator, Figure 5 yes Figure 4 Sectional view of plane A-A in the center; Figure 4 In the process, the circulating water enters the serpentine circulating water channel through the water inlet 6; the water-cooled radiator is divided into a base plate and a cover plate for processing and molding, but because the distance between adjacent water channels is narrow, it cannot meet the size requirements of the process step 7, so the corresponding The abutment and the cover between the adjacent water channels are designed as an overlapping structure, and the abutment and the cover are connected by adhesive technology, such as Figure 5 As shown, a plurality of adhesive joints 5 are formed to block circulating water from flowing between the abutment 1 and the cover plate 2 and prevent the cover plate f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Coating thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com