Method for recycling waste silicon nitride combined with silicon carbide bricks produced by aluminum electrolytic cells

A technology of silicon carbide bricks and waste silicon nitride, which is applied in the fields of resource regeneration and environmental protection, can solve problems such as nitrogen increase in molten steel, impact on clean steel quality, secondary pollution, etc., achieve low cost, realize utilization value, and completely separate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The used silicon carbide bricks come from an aluminum factory

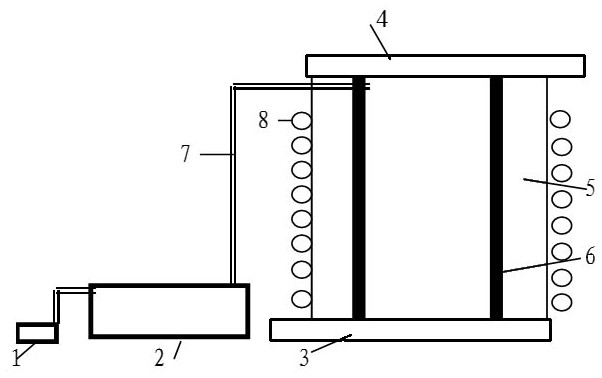

[0031] Weigh 15kg of the used silicon carbide, open the upper cover 4 of the furnace, and put 15kg of the used silicon carbide into it. Then close the lid. Then turn on the vacuum pump 1 to evacuate, so that the vacuum degree is 1 Torr. Turn on the heating power, heat to 1250 ° C, keep the temperature for 6 h, and end when no gas is released. After cooling down, open the lower lid of the furnace and let out the residue from the furnace, while removing the cooled electrolyte from the cooling chamber. It is analyzed and the results are shown in the following table:

[0032] AlF 3

[0033] Therefore, the separation effect is good. The yield rate reached 99%. The recovered electrolyte can be returned to the aluminum plant for reuse, while the recovered silicon carbide can be used as a raw material for the production of silicon carbide products or as a raw material for metallurgical deoxidizer...

Embodiment 2

[0035] The used silicon carbide bricks come from an aluminum factory

[0036] Weigh 20kg of used silicon carbide bricks, open the upper cover 4 of the furnace, and put 20kg of used silicon carbide bricks in. Then close the lid. Then turn on the vacuum pump 1 to evacuate, so that the vacuum degree is 1 Torr. Turn on the heating power, heat to 1300 ° C, keep the temperature for 6 h, and end when no gas is released. After cooling, open the lower lid of the stove and let the residue out of the stove. At the same time, the cooled electrolyte in the cooling chamber was taken out. Analyze it. The results are shown in the table below:

[0037] AlF 3

[0038] Therefore, the separation effect is good. The yield rate reached 99%. The recovered electrolyte can be returned to the aluminum plant for reuse, while the recovered silicon carbide can be used as a raw material for the production of silicon carbide products or as a raw material for metallurgical deoxidizers. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| process yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com