Heat insulation elastic non-woven material manufactured by utilizing waste textile fibers and preparation method thereof

A technology of non-woven materials and textile fibers, applied in non-woven fabrics, textiles, papermaking, fiber processing, etc., can solve problems such as unstable fiber structures, and achieve the effects of simple methods, hygienic guarantees, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

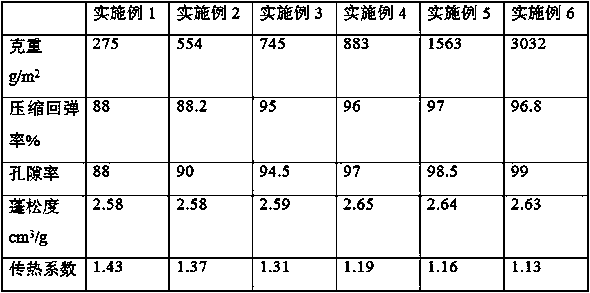

Embodiment 1

[0029] This embodiment provides a method for preparing thermal insulation elastic felt from waste textile fibers, comprising the following steps:

[0030] 1. Tear into pieces: send the waste textiles into two parallel three-knife cutting machines to form cloth pieces with a size of 5*15cm. The speed of the three-knife cutting machines is set at 150 stabs / min;

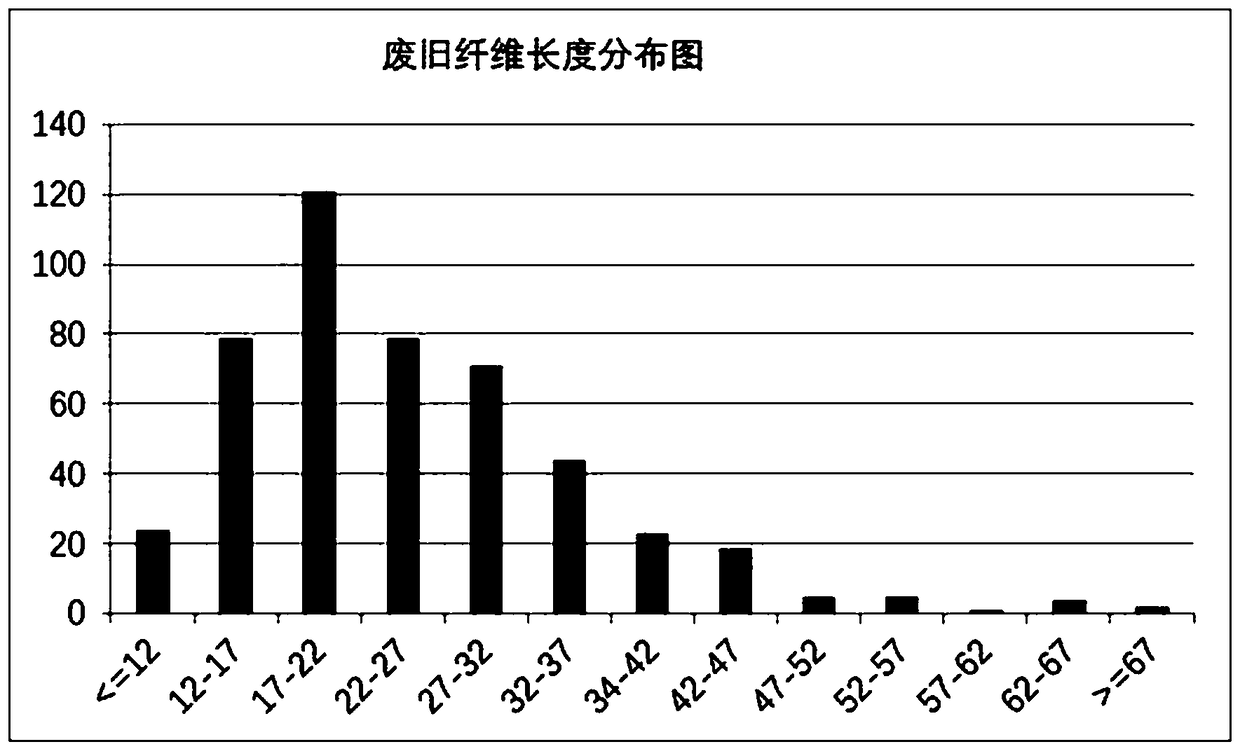

[0031] 2. Cracking into fibers: the cloth cut in step 1 is sent to the foreign fiber separator after two openings, to separate buttons and zippers, and then through two fine openings to loosen them into loose fibers to form a waste fiber mixture , set the speed of the rough opening structure to 350r / min; the preferred feature of the rough opening feeder is a saw-toothed opening structure supporting arc-shaped teeth, the inner angle of the optimal arc-shaped teeth is 75°, the axial tooth spacing is 3mm, and the circumference The pitch is 20mm.

[0032] 3. Packing: Feed the waste fiber mixture into the fiber baler, and w...

Embodiment 2

[0037] This embodiment provides a method for preparing thermal insulation elastic felt from waste textile fibers, comprising the following steps:

[0038] 1. Tear into pieces: Send the waste textiles to two parallel three-knife cutting machines to form cloth pieces of 5*10cm in size. The speed of the three-knife cutting machines is set at 195 stabs / min;

[0039]2. Cracking into fibers: the cloth cut in step 1 is sent to the foreign fiber separator after two openings, to separate buttons and zippers, and then through two fine openings to loosen them into loose fibers to form a waste fiber mixture , set the speed of the rough opening structure to 350r / min; the preferred feature of the rough opening feeder is a sawtooth opening structure with arc-shaped teeth, the inner angle of the optimal arc-shaped teeth is 95°, the axial tooth spacing is 6mm, and the circumference The vertical spacing is 36mm.

[0040] 3. Packing: Feed the waste fiber mixture into the fiber baler, and withst...

Embodiment 3

[0045] This embodiment provides a method for preparing thermal insulation elastic felt from waste textile fibers, comprising the following steps:

[0046] 1. Tear into pieces: send the waste textiles into two parallel three-knife cutting machines to form cloth pieces with a size of 15*15cm. The speed of the three-knife cutting machines is set at 160 stabs / min;

[0047] 2. Cracking into fibers: the cloth cut in step 1 is sent to the foreign fiber separator after two openings, to separate buttons and zippers, and then through two fine openings to loosen them into loose fibers to form a waste fiber mixture , set the speed of the coarse opening structure to 350r / min; the preferred internal angle of the arc-shaped teeth is 95°, the axial tooth spacing is 3mm, and the circumferential spacing is 36mm.

[0048] 3. Packing: Feed the waste fiber mixture into the fiber baler, and withstand the pressure of 40Mpa to form a bulk density of 390kg / m 3 The fiber package, the size of the fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com