Hollow anti-slide pile with drainage structure and its construction method

A drainage structure and anti-slide pile technology, which is applied in foundation structure engineering, excavation, construction, etc., can solve the problems of not necessarily economical, anti-slide pile landslide thrust effect is not necessarily reliable, etc., to reduce the amount of use and easy to control the construction quality , good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

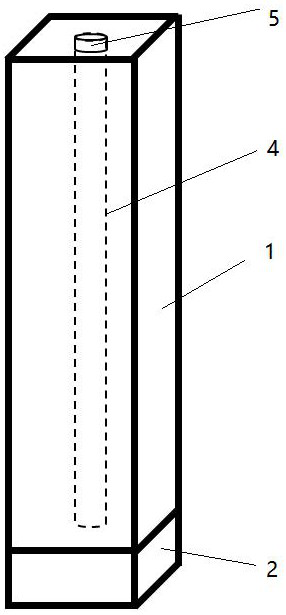

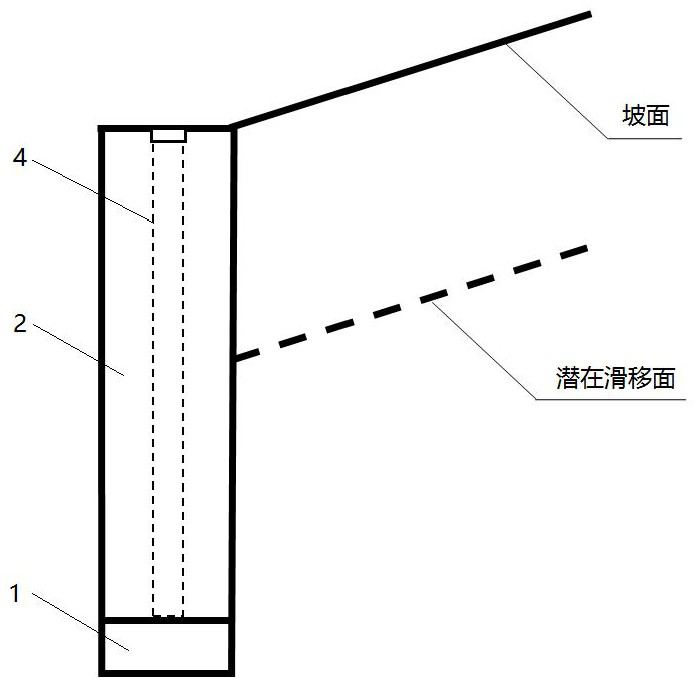

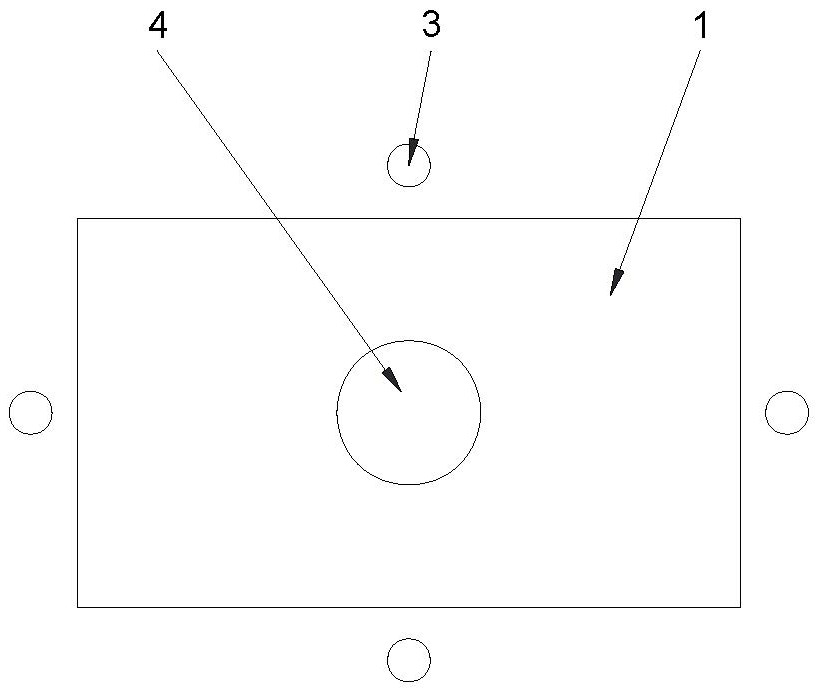

[0054] like figure 1 Shown is a schematic structural view of Embodiment 1 of the hollow anti-slide pile with drainage structure of the present invention. The hollow anti-slide pile with drainage structure in this embodiment includes a pile hole 6 extending downwards below the potential sliding surface, a pile body 1 is arranged in the pile hole 6, and a water-permeable hole is arranged between the pile body 1 and the bottom surface of the pile hole. Layer 2, between the pile body 1 and the inner wall of the pile hole or outside the pile body 1, there is a seepage well 3 that communicates with the aquifer 2 and is used to divert the groundwater around the pile body 1 to the aquifer 2. In this embodiment The seepage well 3 is filled with permeable material, the pile body 1 is provided with a central cavity 4 connected with the permeable layer 2, and the central cavity 4 is equipped with a device for discharging the permeable layer 2 into the central cavity 4. groundwater pumpin...

Embodiment 2

[0080] like Figure 9 Shown is a schematic structural view of Embodiment 1 of the hollow anti-slide pile with drainage structure of the present invention. The hollow anti-slide pile with drainage structure in this embodiment of this embodiment includes a pile hole 6 extending downward to below the potential slip surface, and a pile body 1 is arranged in the pile hole 6, and the bottom surface between the pile body 1 and the pile hole A permeable layer 2 is arranged between them, and a seepage well 3 connected with the permeable layer 2 and used to divert the groundwater around the pile body 1 to the aquifer 2 is provided between the pile body 1 and the inner wall of the pile hole or outside the pile body 1 , the seepage well 3 in this embodiment is filled with permeable material, the pile body 1 is provided with a central cavity 4 communicating with the permeable layer 2, and a central cavity 4 is installed in the central cavity 4 for discharging the permeable layer 2 into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com