Prefabricated truss type light steel frame - punched thin steel plate - concrete composite wall

A technology of steel tube concrete and thin steel plate, applied to walls, ceramic molding machines, manufacturing tools, etc., can solve the problems of poor seismic capacity, low bearing capacity, poor stability, etc., to increase lateral stiffness and seismic capacity, simple construction, The effect of good bearing capacity and earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

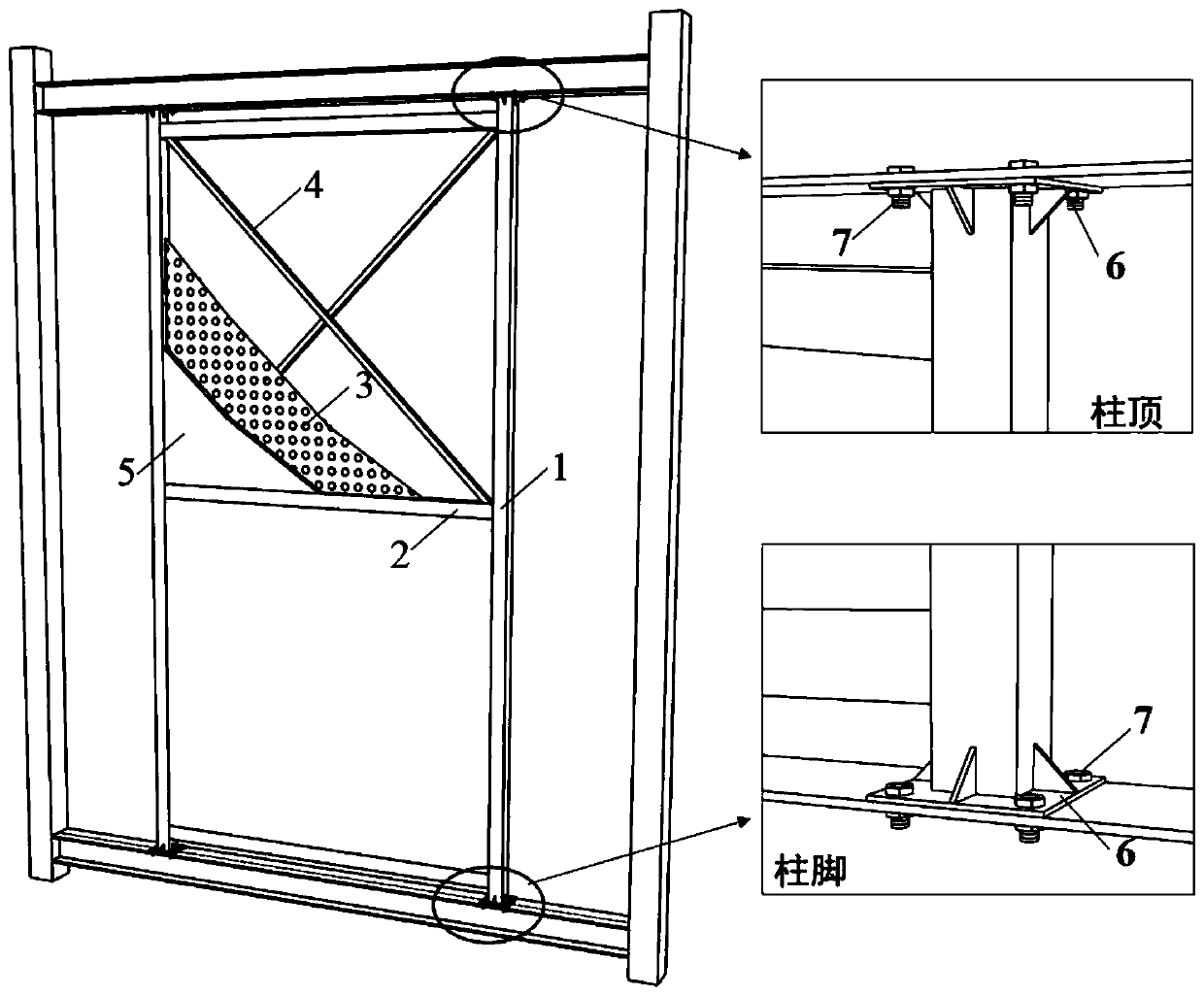

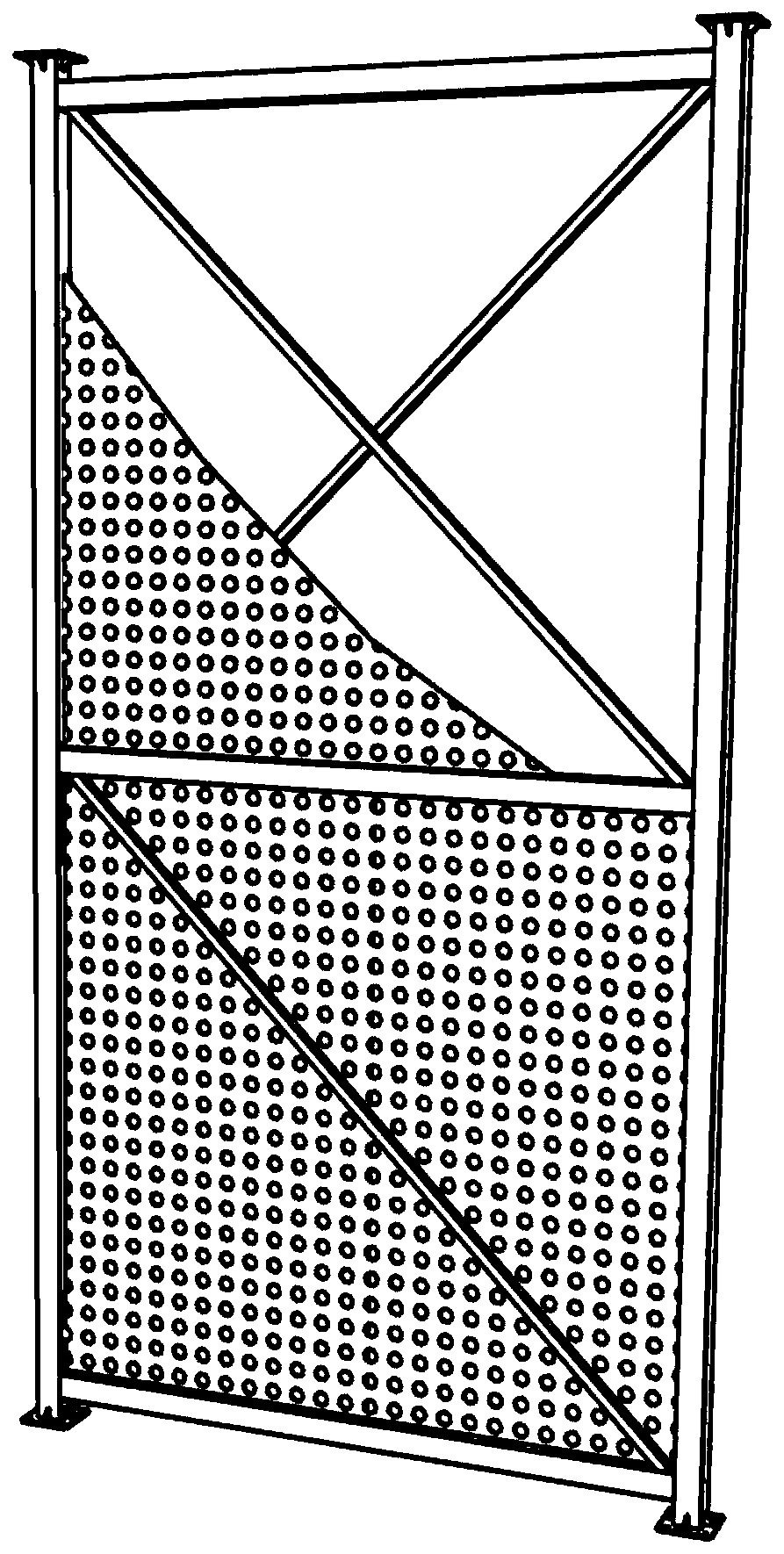

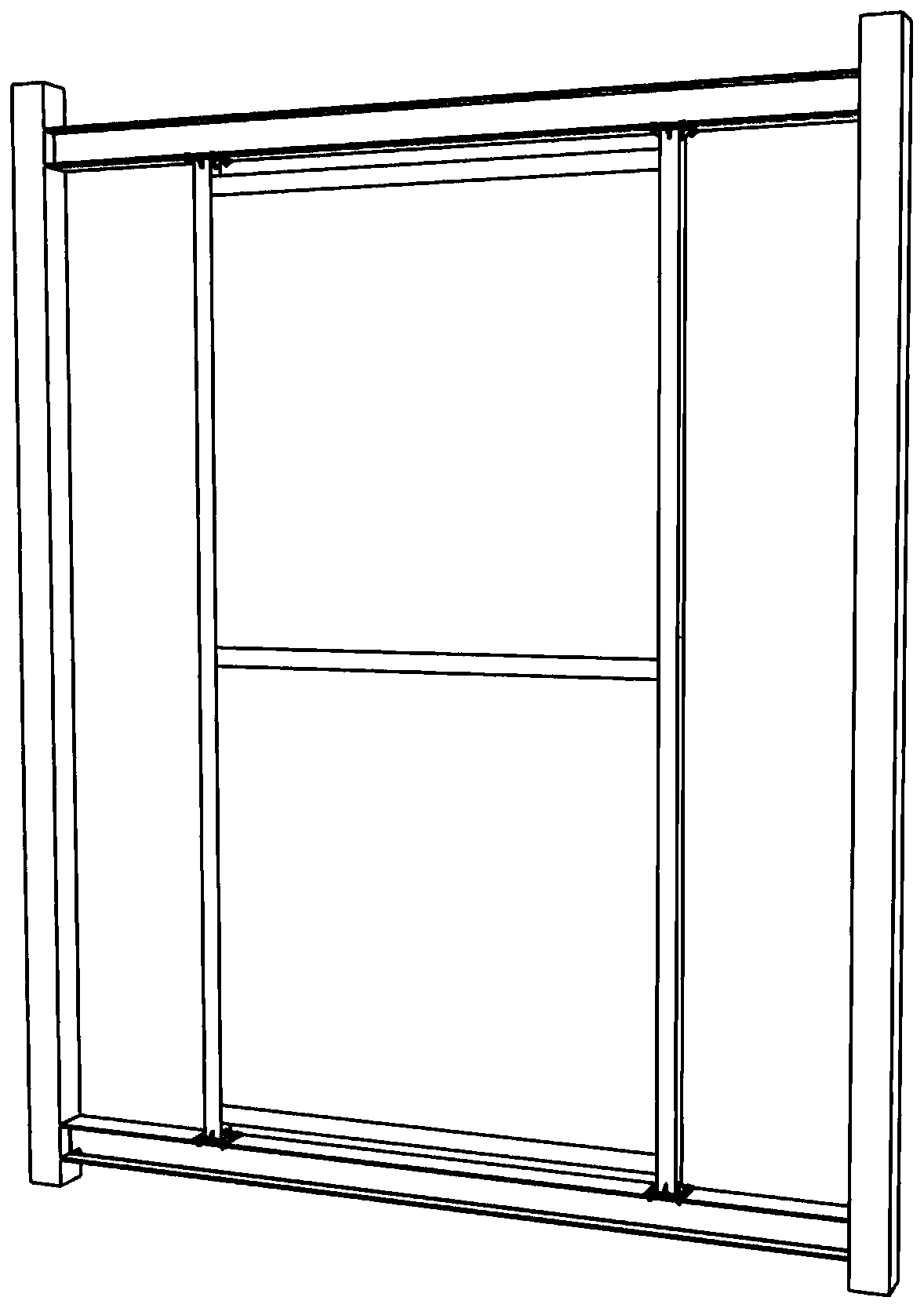

[0028] The prefabricated truss-type light steel frame in the invention - punched thin steel plate - concrete composite wall, combined with attached Figures 1 to 3 The preparation method of the present invention is illustrated as follows:

[0029] The first step: pour concrete in the steel pipe and maintain it to form the CFST frame column, the CFST frame beam and the CFST truss rib of the wall; The end plates are respectively welded on the top and bottom of each CFST frame column; the CFST frame column and the CFST frame beam are welded to form a composite wall light steel frame frame.

[0030] Step 2: Weld the punched thin steel plate in the frame of the light steel frame of the composite wall, and then arrange the concrete-filled steel tube truss ribs on both sides of the punched thin steel plate, and both ends of the ribs are welded and fixed on the frame frame of the light steel frame of the composite wall. Form a composite wall steel skeleton.

[0031] The third step: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com