Method for quickly measuring angles of flange holes

A flange hole, fast technology, applied in the direction of angle/taper measurement, etc., can solve the problems of inappropriate economy or efficiency, large error in marking measurement, easy to scratch the surface of parts, etc., to achieve easy operation, improve accuracy, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

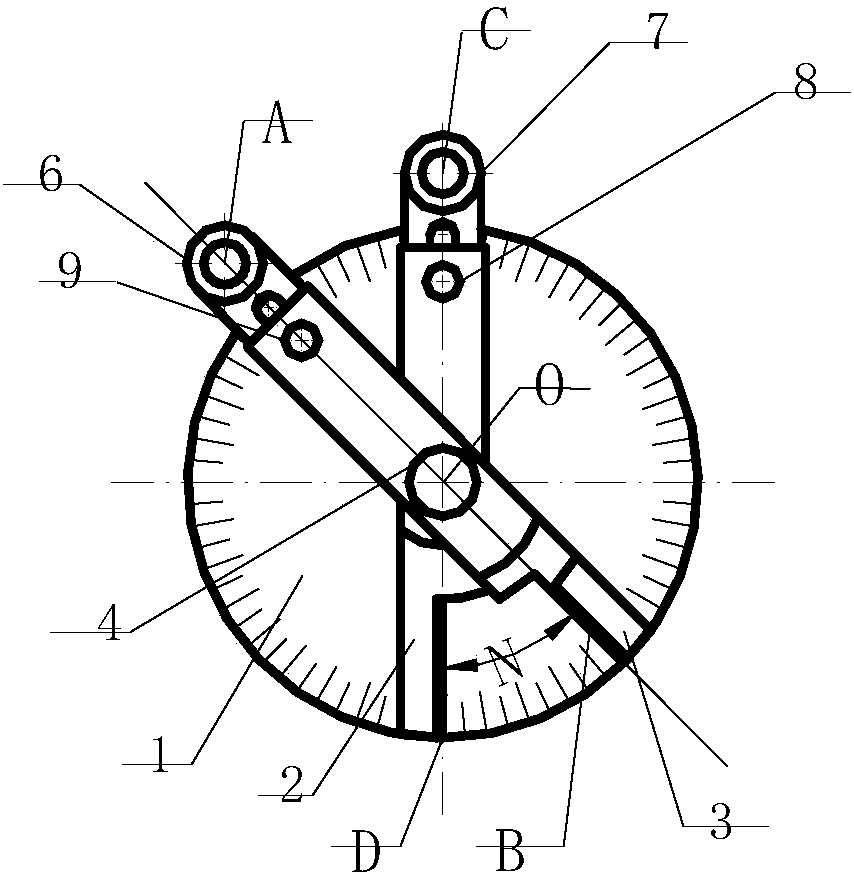

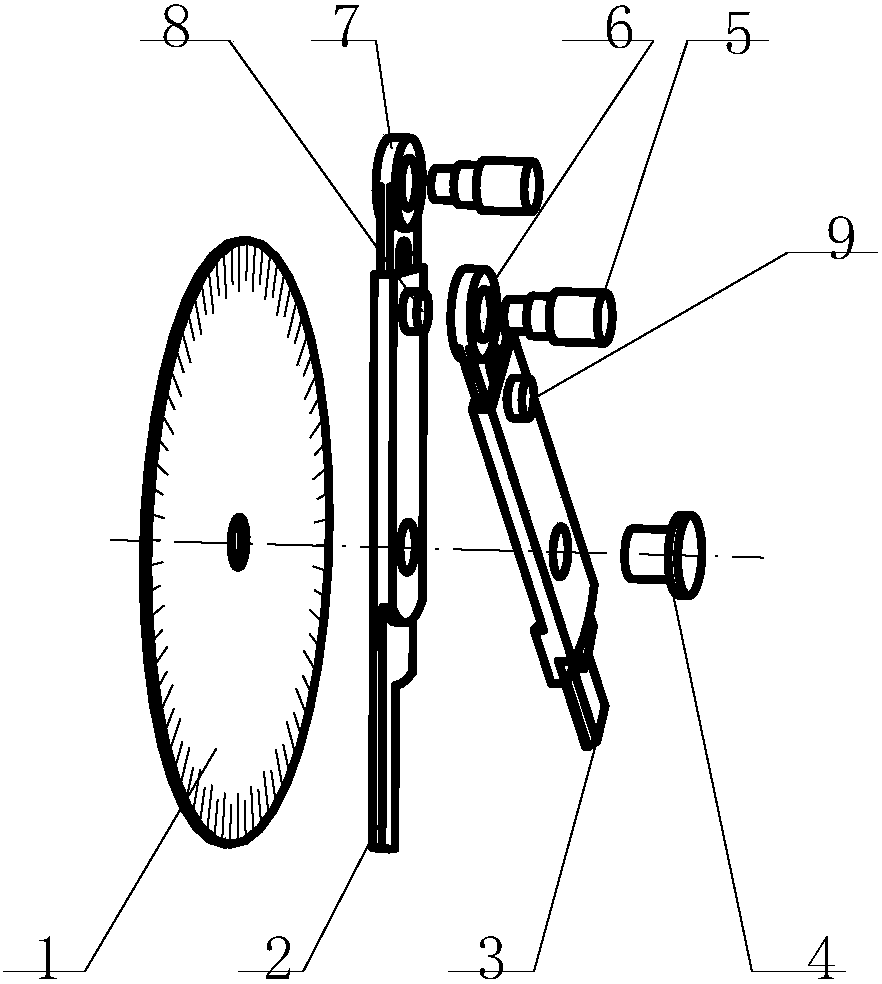

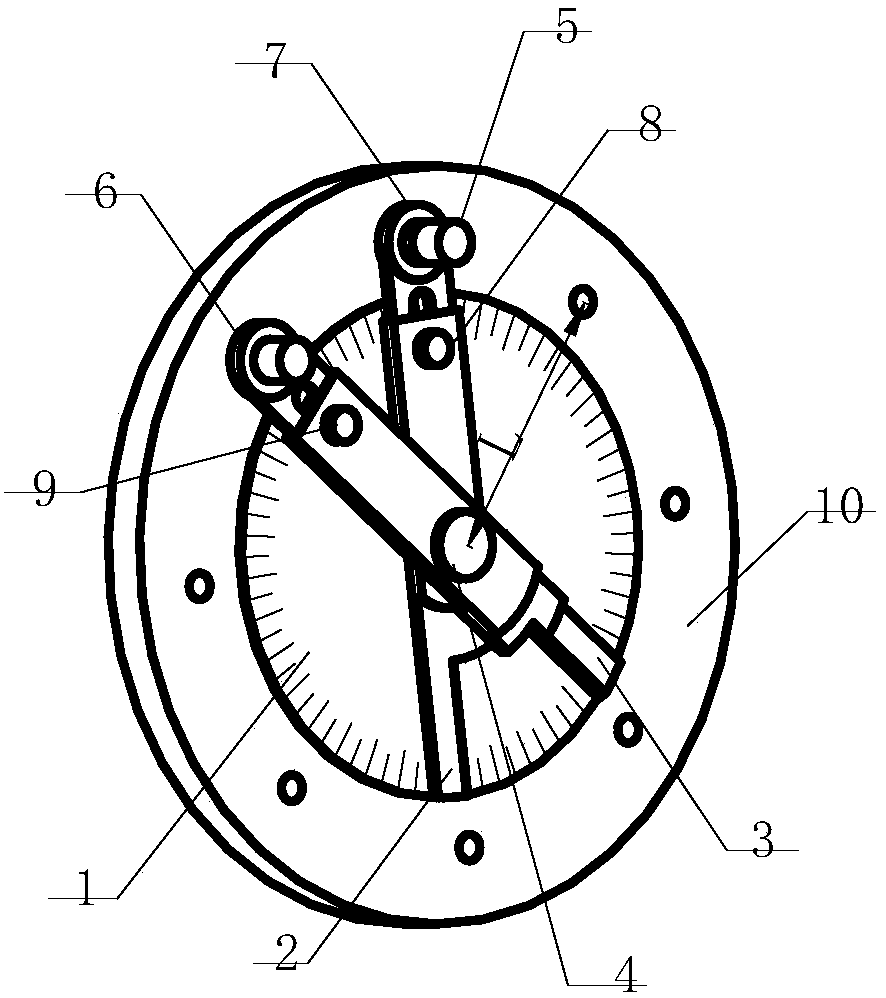

[0017] refer to Figure 1-Figure 3 . According to the present invention, first, according to the distance L between the flange hole of the part 10 to be inspected and the flange center point as the radius, an angle plate 1 with a measuring scale is made with a size smaller than the distance L, and an angle plate 1 is made on the axis of the angle plate 1. Rotate around the central hole O axis of the rotating shaft 4, the main angle ruler 2 and the auxiliary angle ruler 3 that are cross-connected, wherein, the same side radial direction of the main angle ruler 2 and the auxiliary angle ruler 3 are shaped with opposite symmetrical L-shaped notches, and the L-shaped notch sides D, The extension line of the L-shaped notch side B passes through the central hole O and the hole system plunger positioning hole A on the opposite end, and the center of the hole system plunger dynamic measurement hole C is on a straight line, forming a scissors differential rotation pair; two shapes The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com