Intelligent pump station drainage scheduling control system

A scheduling control and pumping station technology, which is applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problem of affecting the drainage efficiency of pumping stations, overflowing sewage in local pumping stations, and disorderly drainage of pumping stations To achieve the effect of improving the orderliness of drainage, improving drainage efficiency and prolonging the life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

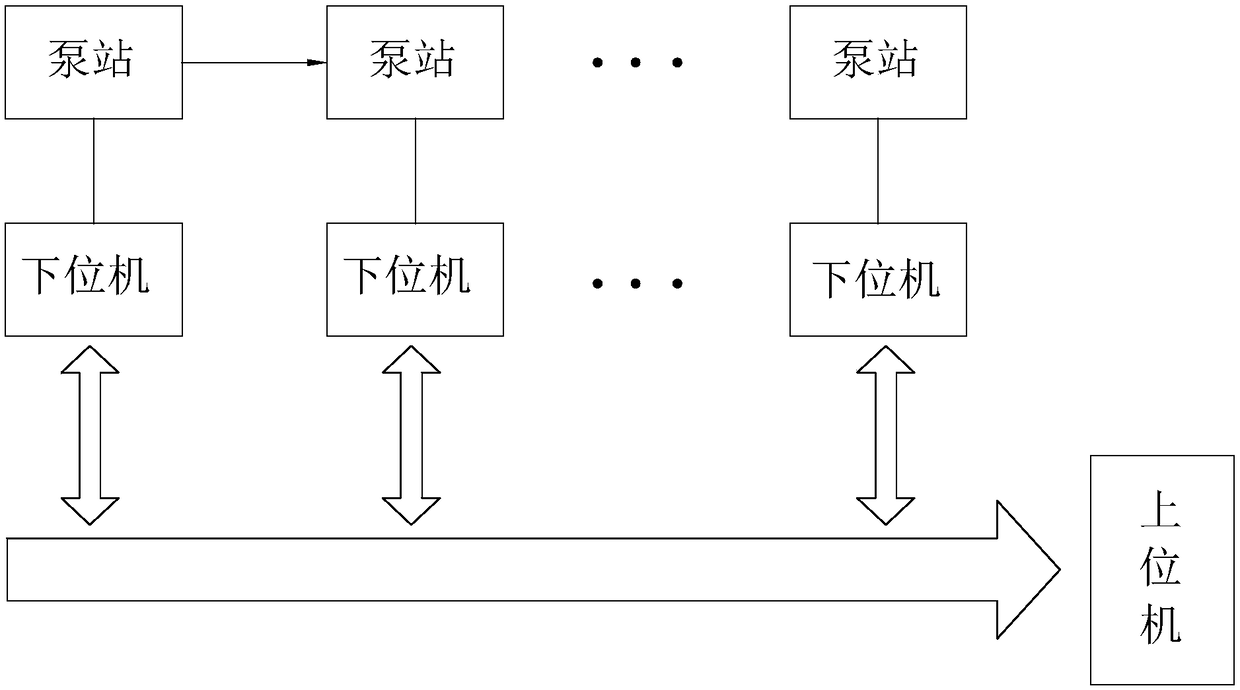

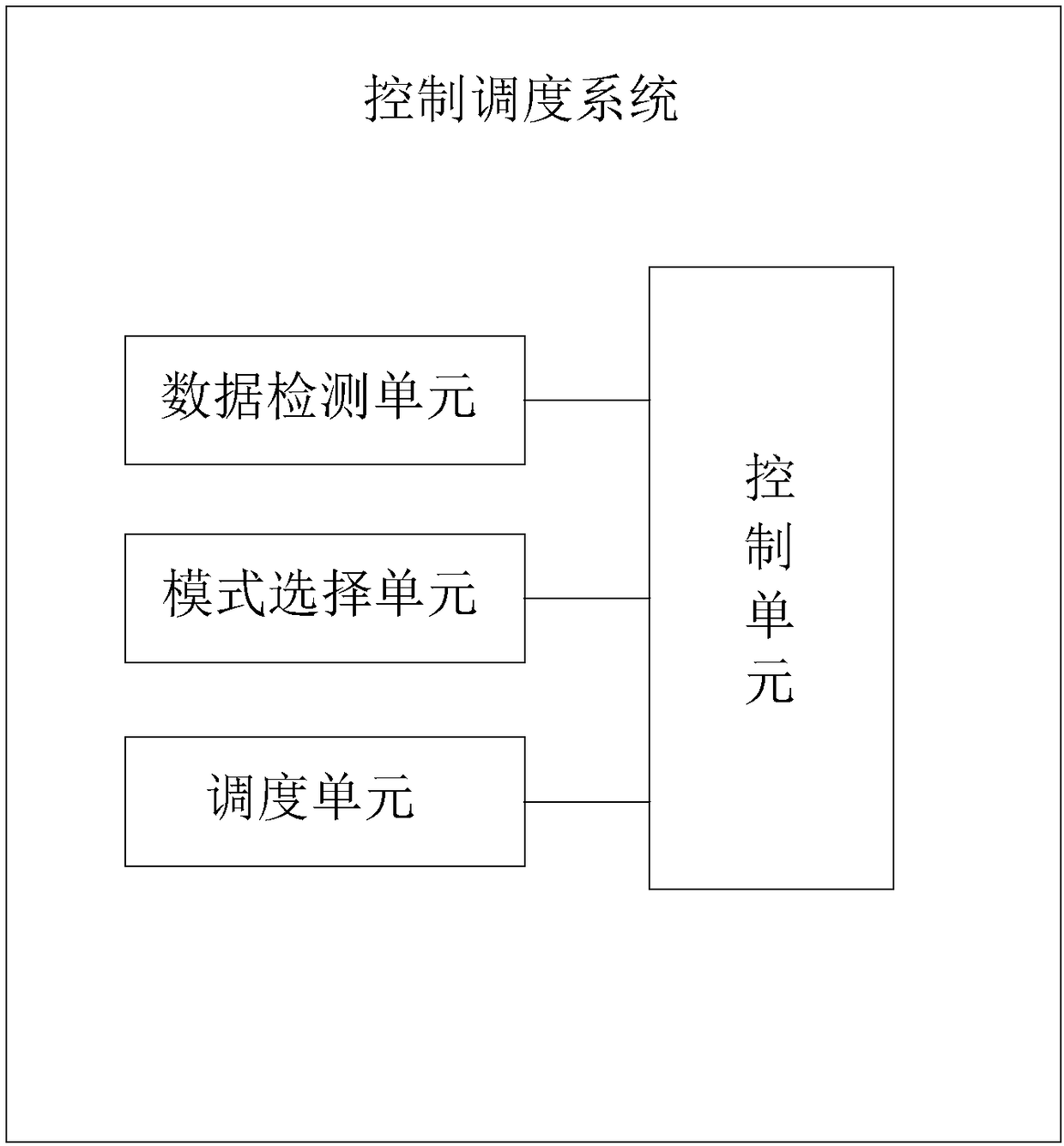

[0059] An intelligent drainage dispatching control system for a pumping station includes a data detection unit, a mode selection unit, a dispatching unit and a control unit, and the data detection unit, the mode selection unit and the dispatching unit are respectively connected to the control unit.

[0060]Each pump station includes water inlet pipes, local water collecting pipes, water inlet pools (or pump pools), water pumps, water outlet pools (or elevated wells), and water outlet pipes connected in sequence. The local water collection pipe is used to collect the sewage collected by the local pipe network and transfer it to the water inlet tank. The water pump is arranged in the pump room, and the water pump is driven by an electric motor. Among them, the water inlet pool, the pump pool and the water outlet pool or the high level well of the pumping station are equipped with liquid level sensors, and the liquid level sensors are used to output the liquid level signals of th...

Embodiment 2

[0082] The mode selection unit is also configured with a plurality of middle-level mode interfaces, and the middle-level mode interfaces are used to obtain user selection requests;

[0083] The control unit is further configured to: establish an energy-saving mode, a long-life mode and a high-efficiency mode corresponding to each middle mode interface, and request to enter the corresponding energy-saving mode, long-life mode and high-efficiency mode based on user selection. in,

[0084] In the energy-saving mode, the dispatching unit calculates the energy efficiency coefficient and establishes an energy-saving model based on the obtained power signal and flow signal; the control unit calculates the energy efficiency coefficient based on the energy efficiency coefficient, the energy-saving model, and the selected constant liquid level mode, constant pressure mode or current limiting mode, Control the frequency conversion operation of each water pump in the pumping station accor...

Embodiment 3

[0129] The data detection unit is also used to obtain the flow signal of the local water collecting pipe in a single pumping station;

[0130] Wherein, when the data detection unit cannot directly obtain the flow signal of the local water collecting pipe in a single pumping station, the dispatching unit can calculate the local water collecting pipe flow through the flow rate of the upstream and downstream pumping stations, and the local water collecting pipe Intake flow = the sum of the flow from the pump station to the downstream pump station - the sum of the flow from the upstream pump station to the pump station;

[0131] The mode selection unit is also configured with a high-level mode interface, and the high-level mode interface is used to obtain the user's selection request;

[0132] The control unit is also configured to: establish an automatic mode corresponding to the high-level mode interface, and request to enter the corresponding automatic mode based on the user's ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com