Screw nail for fixing fractured cancellous bone

A technology of screw nails and cancellous bone, applied in the direction of fixator, internal bone synthesis, external plate, etc., can solve the problems of large internal fixation, large bone loss, easy slippage and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

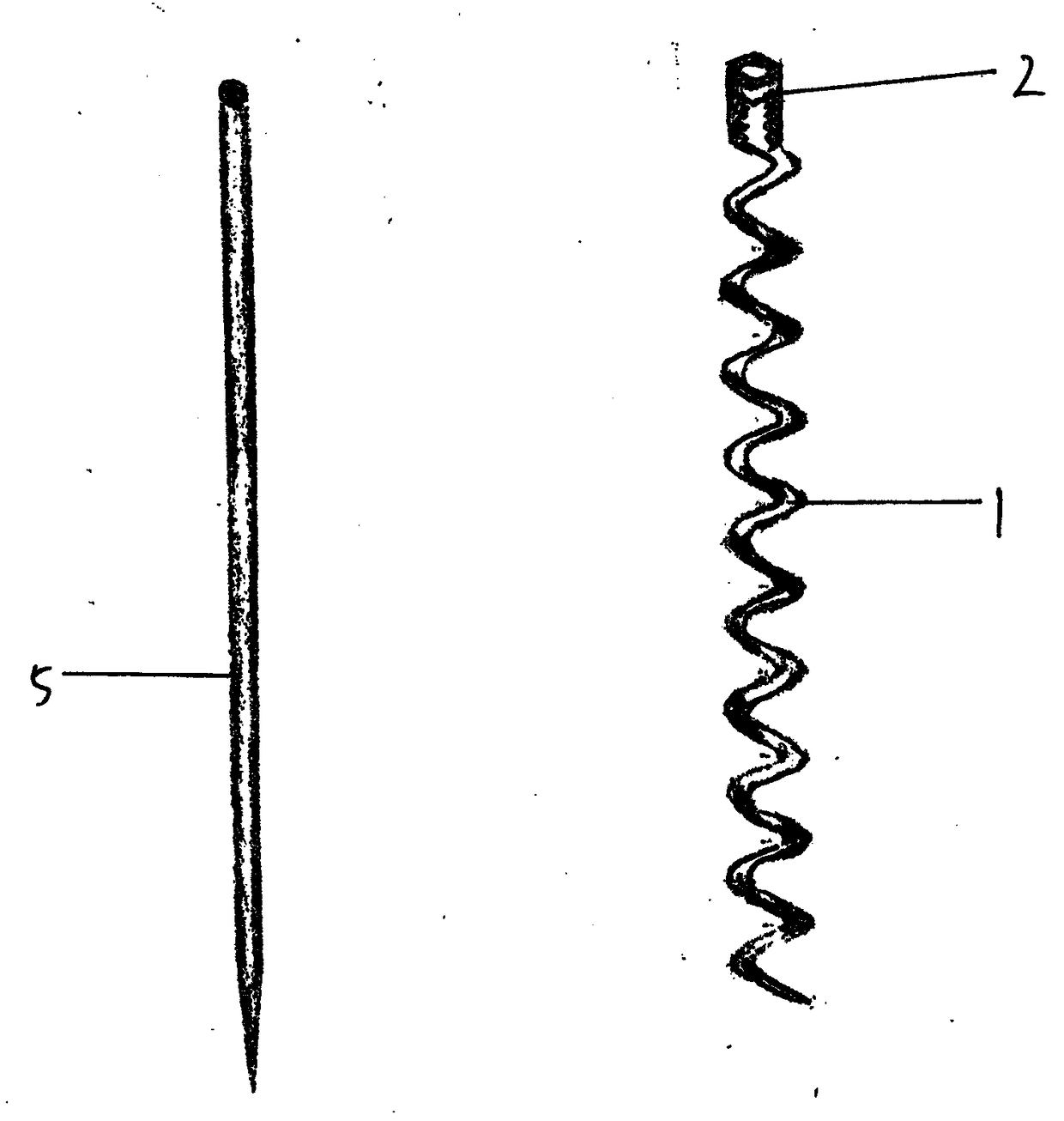

[0010] When the screw nail is used alone like figure 1 Shown: After reduction of cancellous bone fracture, temporary fixation with Kirschner wire. At the same time, a navigation Kirschner wire (5) is implanted. After confirming that the position of the navigation Kirschner wire is satisfactory, measure the length of the nail to be implanted. According to the length of the screw-in nail and the pointing position of the tip of the nail body, mark the selected entry point with the screw-in nail, and then use an electric drill at the selected point to open the window according to the selected trajectory of the screw-in nail until the cancellous bone is exposed. Select the measured spiral nail and place the screw in the wrench, and screw in the spiral nail along the guide Kirschner wire.

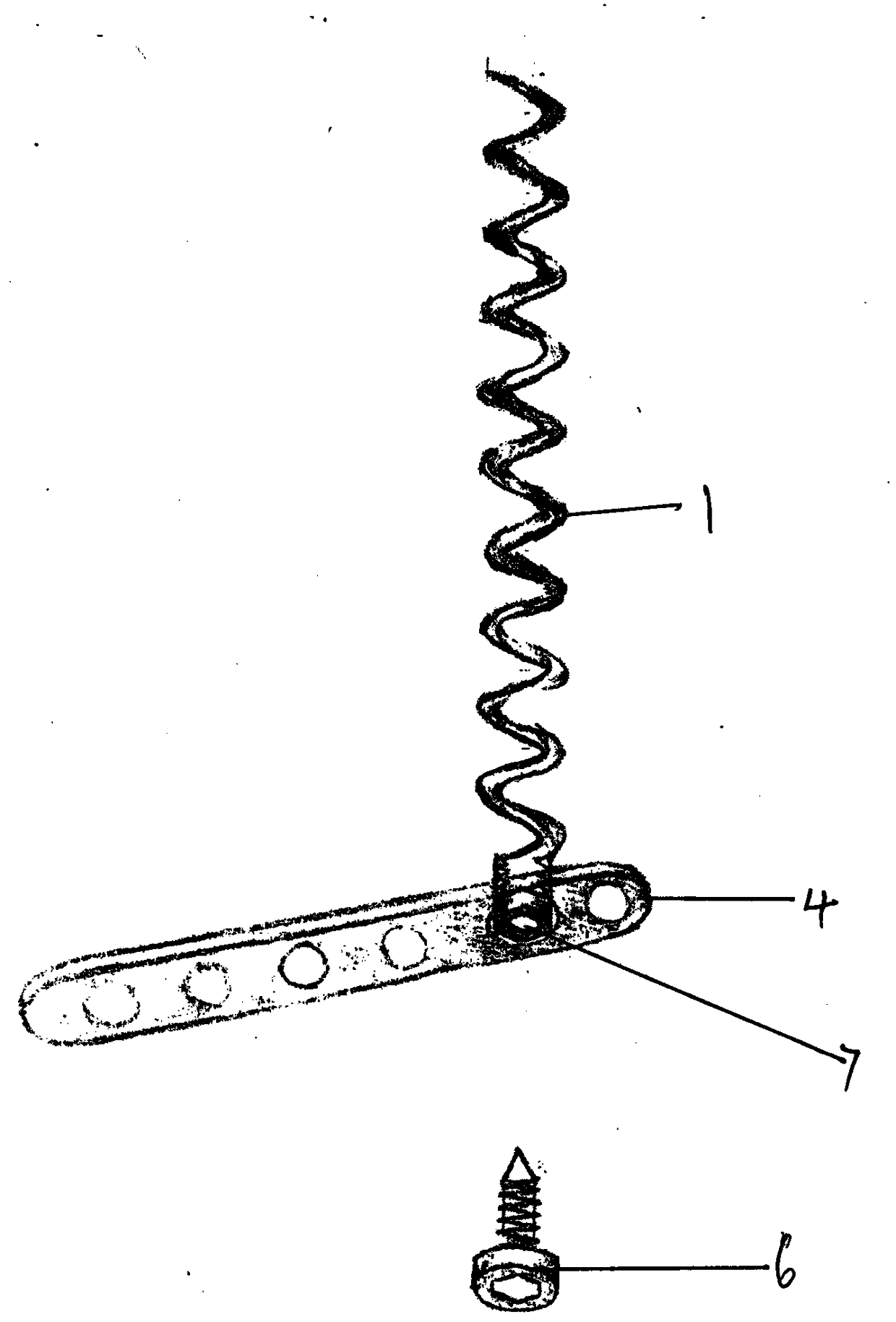

[0011] When the screw nail and the bone plate are combined with the screw nail to fix the intertrochanter and other parts of the fracture, such as figure 2 Shown: After the screw nail is implante...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com