Fixture special for gearbox shell machining

A special fixture and gearbox technology, which is applied in manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve problems such as position error, reducing machining accuracy, and reducing clamping accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

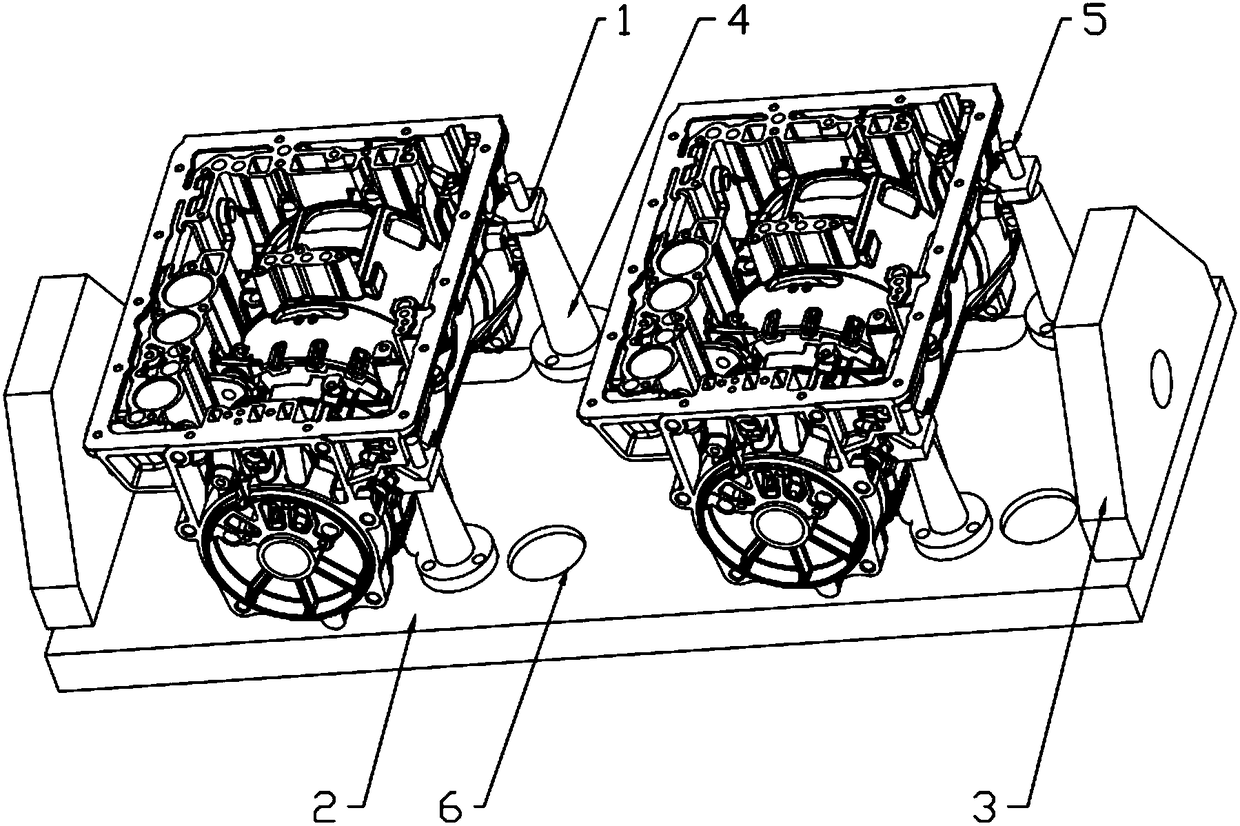

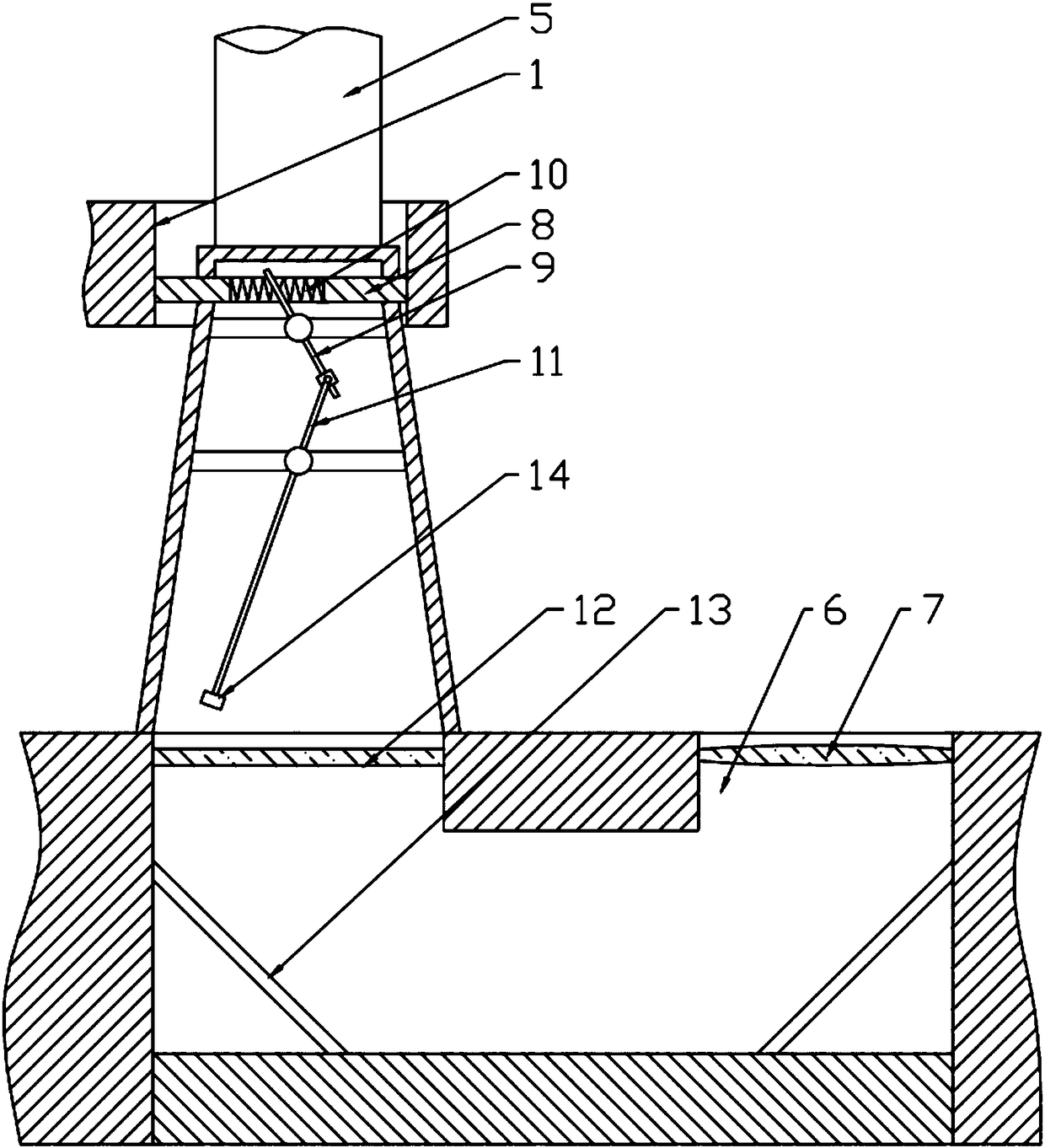

[0016] The reference signs in the drawings of the specification include: mounting hole 1, bridge plate 2, connecting seat 3, positioning column 4, screw rod 5, U-shaped tunnel 6, magnifying glass 7, slider 8, lever 9, compression spring 10, magnifying Rod 11, reference sheet 12, mirror 13, laser light 14.

[0017] The embodiment of the special fixture for gearbox housing processing is basically as attached figure 1 And attached figure 2 Shown: Including CNC turntable, hydraulic tailstock and bridge plate 2, the CNC turntable and hydraulic tailstock are equipped with turntables on the inside, and the two ends of bridge plate 2 are respectively provided with connecting seats matching the CNC turntable and hydraulic tailstock 3. The connecting seat 3 is used to connect with the turntable. The bridge plate 2 also includes a positioning column 4 made of glass. The positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com