Cross coupling and scroll compressor

A technology of an Oldham coupling and a scroll compressor, applied in the field of scroll compressors, can solve problems such as vibration, and achieve the effects of reducing friction area, reducing weight and enhancing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

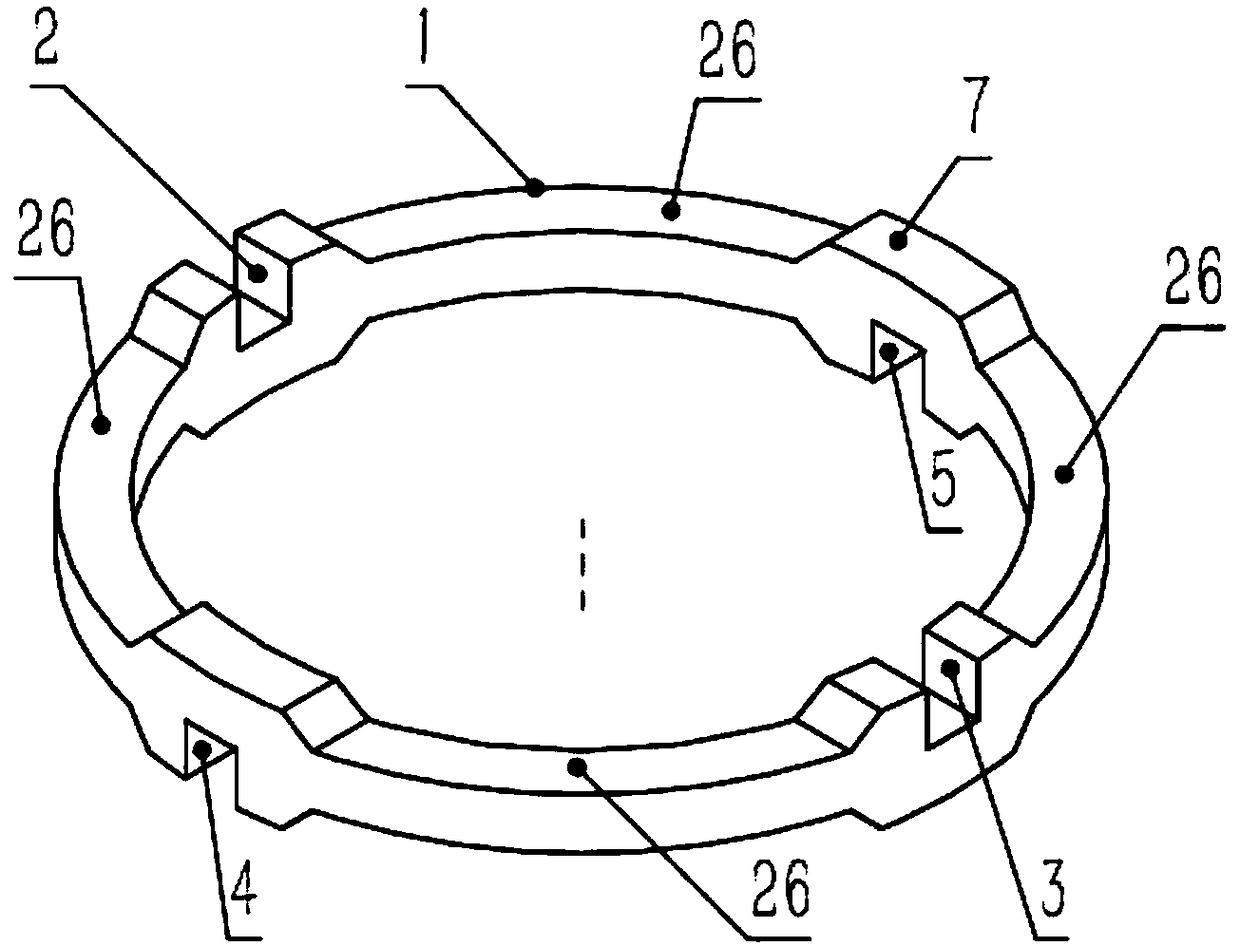

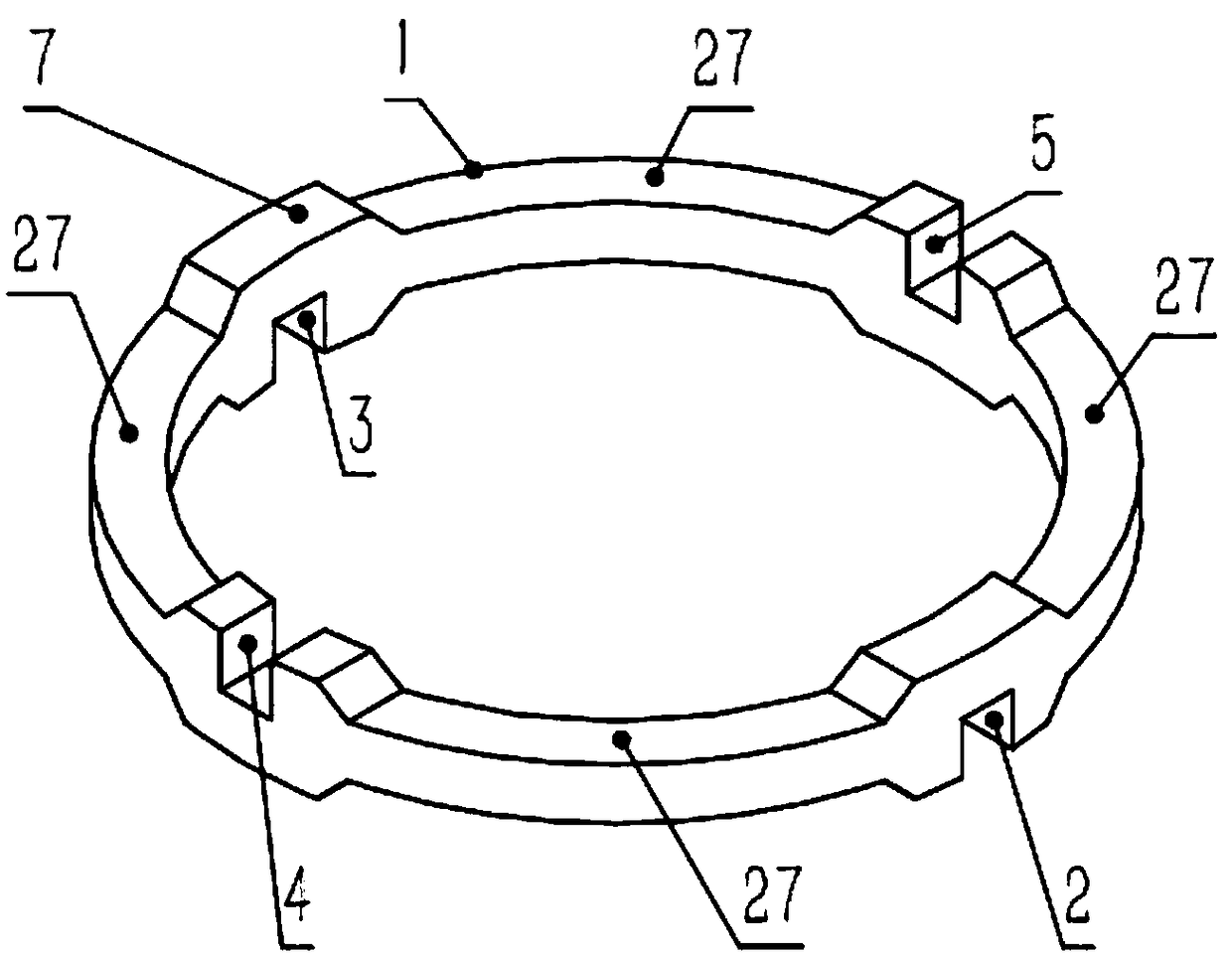

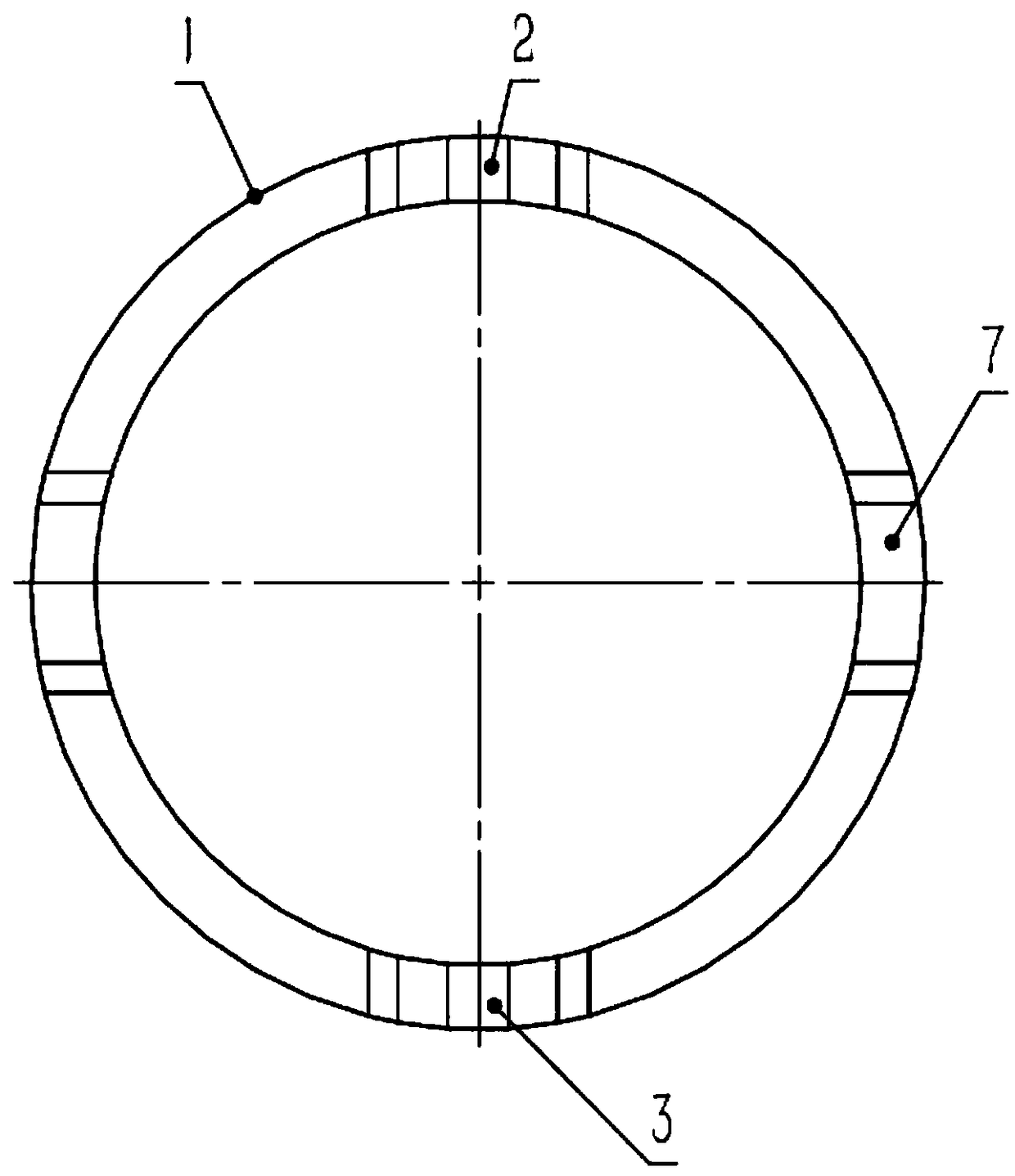

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings:

[0027] See Figure 1-10 As shown, although the structure of the present invention can be applied to many different types of scroll machines, for demonstration purposes, the scroll air compressor is described here.

[0028] Such as Picture 10 Shown is a cross-sectional schematic view of the scroll compressor assembly of the Oldham coupling, the movable scroll and the fixed scroll of the present invention, which includes the Oldham coupling and is indicated by the reference number 1. The scroll compressor includes Oldham coupling 1, fixed scroll 8, orbiting scroll 12, bolt 16, bracket 17, bearing 18, crankshaft 19, motor rotor 20, motor stator 21, middle casing 22, spacer Oil plate 23, lower casing 24. The fixed scroll 8 is fixed to the bracket 17 in the compressor middle casing 22 by bolts 16. The movable scroll 12 cooperates with the fixed scroll 8 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com