Automatic freeze drying machine with high heat uniformity

A freeze-drying machine and uniformity technology, which is used in the direction of drying solid materials without heating, drying, drying solid materials, etc. The problem of drying items being freeze-dried at the same time, to achieve the effect of improving freeze-drying effect, excellent comprehensive performance and improving freeze-drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

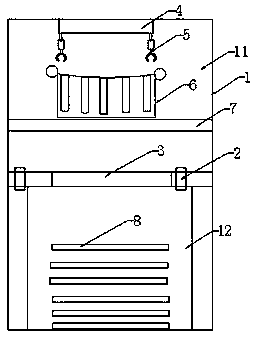

[0025] The present invention discloses a high thermal uniformity automatic freeze-drying machine, comprising a casing 1, said casing 1 including a freeze-drying box 11 and a cold well box 12, the bottom of the freeze-drying box 11 and the top of the cold well box 12 Connect by bolt 2 between; Also have through hole 3 between the bottom of described freeze-drying box 11 and the top of cold trap box 12; Each of the two ends of the driving device 4 has a mechanical gripper 5, and the lifting driving device 4 drives the mechanical gripper 5 to move up and down and translate forward and backward to clamp the suspension ring 63 of the freeze-drying tray 6 to realize Freeze-dried materials enter and exit the freeze-drying box 11; the freeze-drying partition 7 is placed horizontally, and its two ends are embedded and fixed on the inner wall of the freeze-drying box 11, on which the freeze-drying tray 6 is placed.

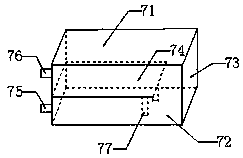

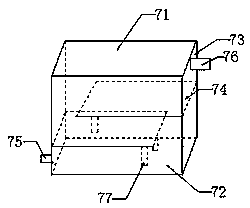

[0026] Described freeze-drying partition 7 comprises upper panel 71, l...

Embodiment 2

[0038] The difference with Embodiment 1 is that the number of the interlayer plates 74 of the freeze-drying partition is an even number, that is, 2, 3, 6..., and the heat transfer medium inlet 75 and the heat transfer medium outlet 76 are located on the two opposite sealing plates. plate 73.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com