Plasticine strip preparation device and preparation method

A plasticine and rubber technology, which is used in manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of low production efficiency and poor dimensional consistency, and achieve the effects of improving work efficiency, reducing workload and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

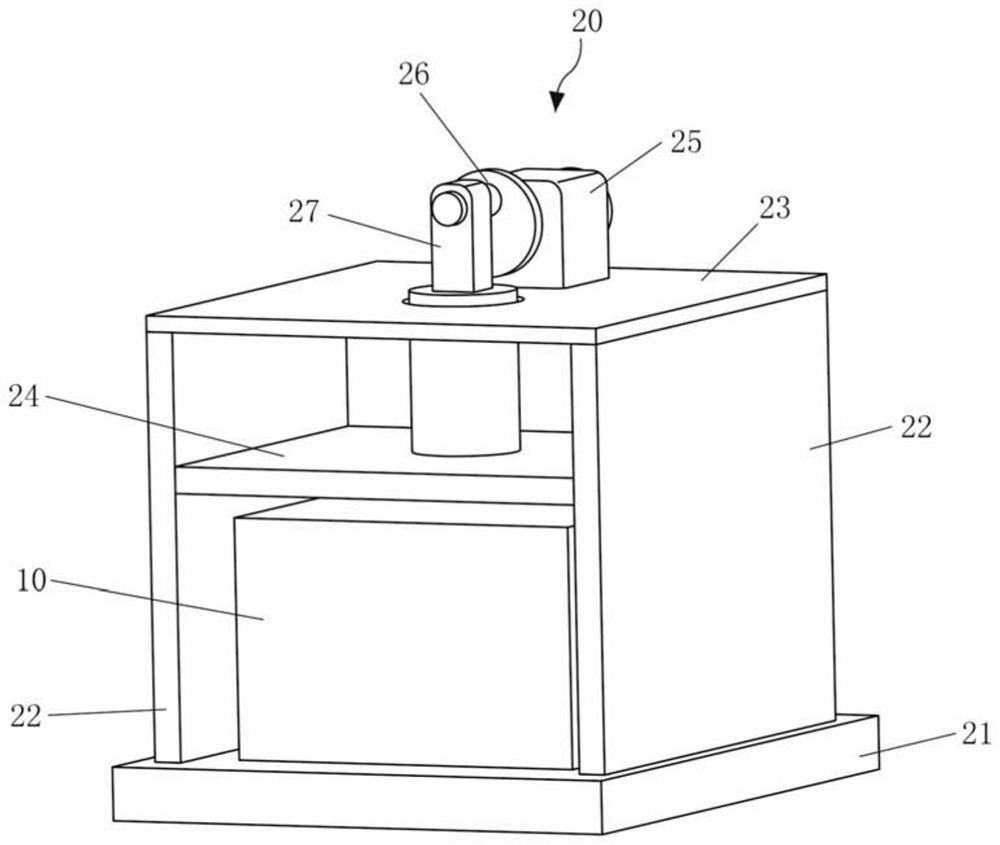

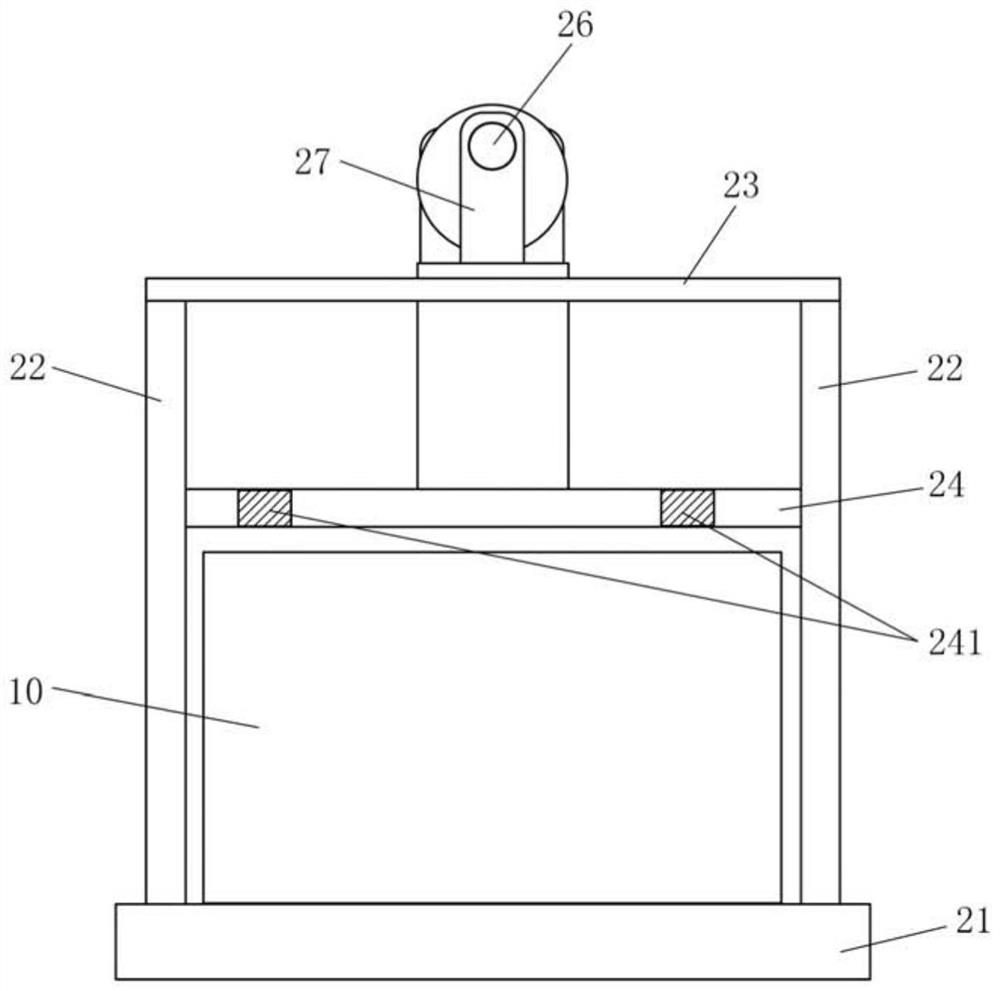

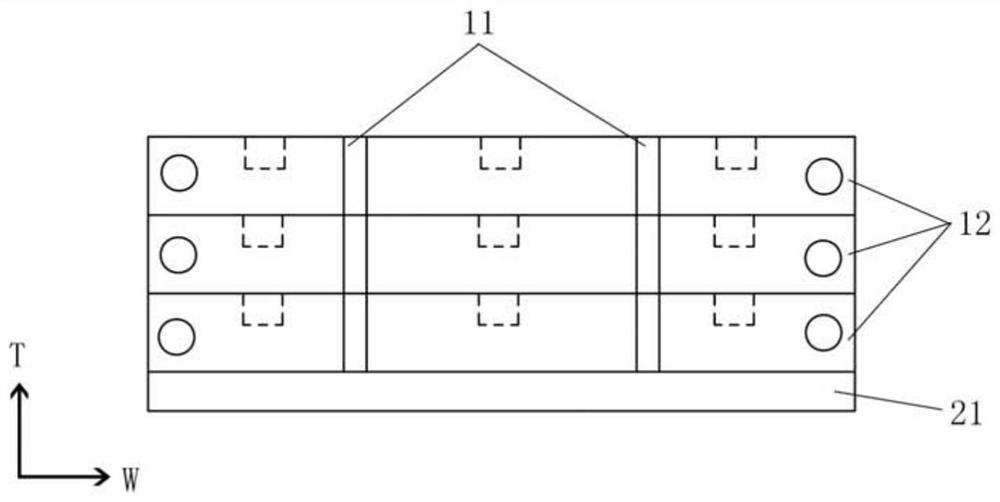

[0070] The method for preparing a plasticine strip of the present invention may include: preparing a block-shaped plasticine; and cutting the block-shaped plasticine along a horizontal direction and a vertical direction to obtain a plasticine strip.

[0071] As an example, the plasticine forming module 10 described above can be used to prepare block-shaped plasticine. When preparing the block plasticine, the cavity or inner cavity of the plasticine forming module 10 can be filled, especially the dead space of the cavity, by manual operation, for example. In addition, the filling amount of plasticine can be 1-2 cm higher than the upper edge of the plasticine forming module 10 to ensure that the plasticine forming module 10 can still be fully filled with plasticine after compacting and flattening the plasticine. the chamber.

[0072] After the filling is completed, the plasticine can be tapped, compacted, and flattened by the flattening piece 24, and a pressure sensor 241 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com