Switchgear thermal defect monitoring system, analysis method and comprehensive measuring control device thereof

A monitoring system and switchgear technology, which can be used in measuring devices, measuring electricity, measuring electrical variables, etc., and can solve problems such as incorrect monitoring results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

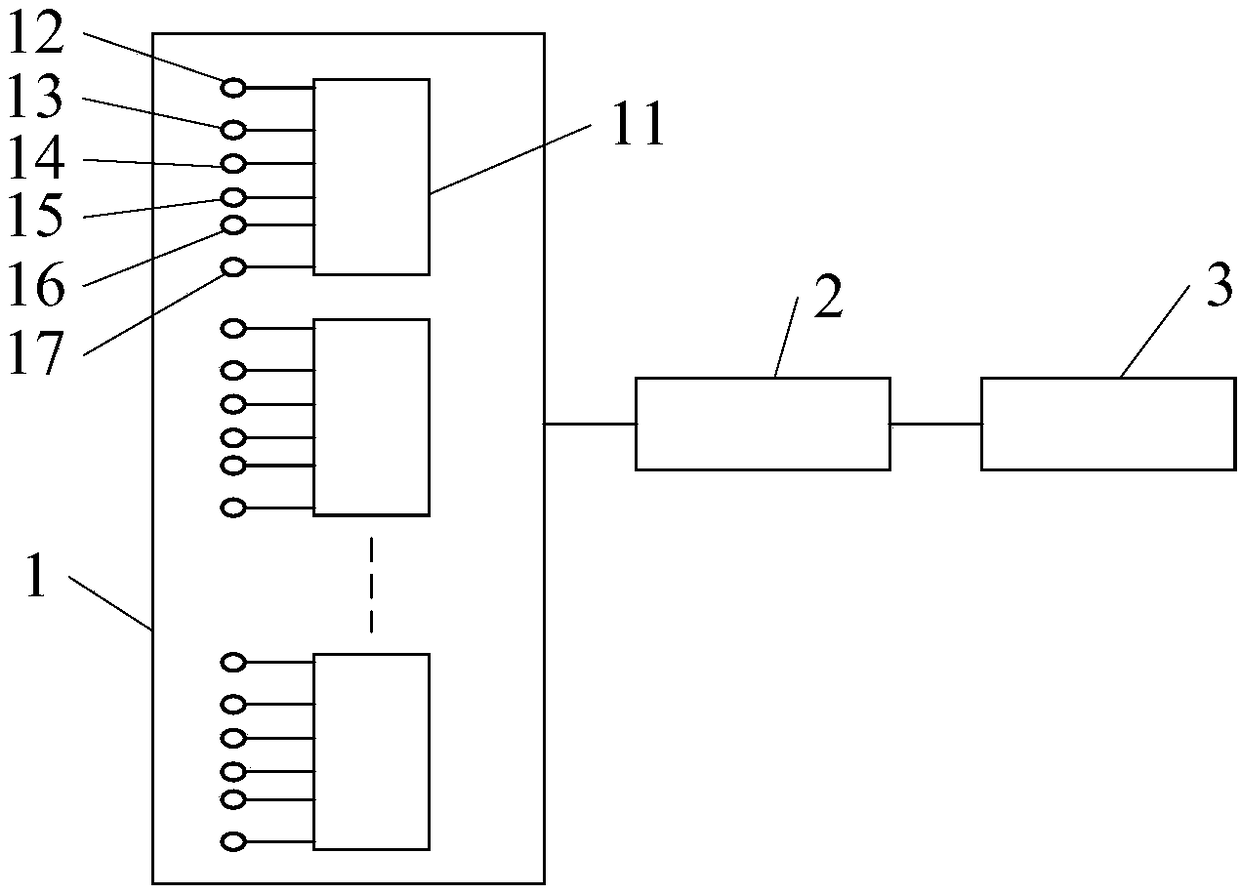

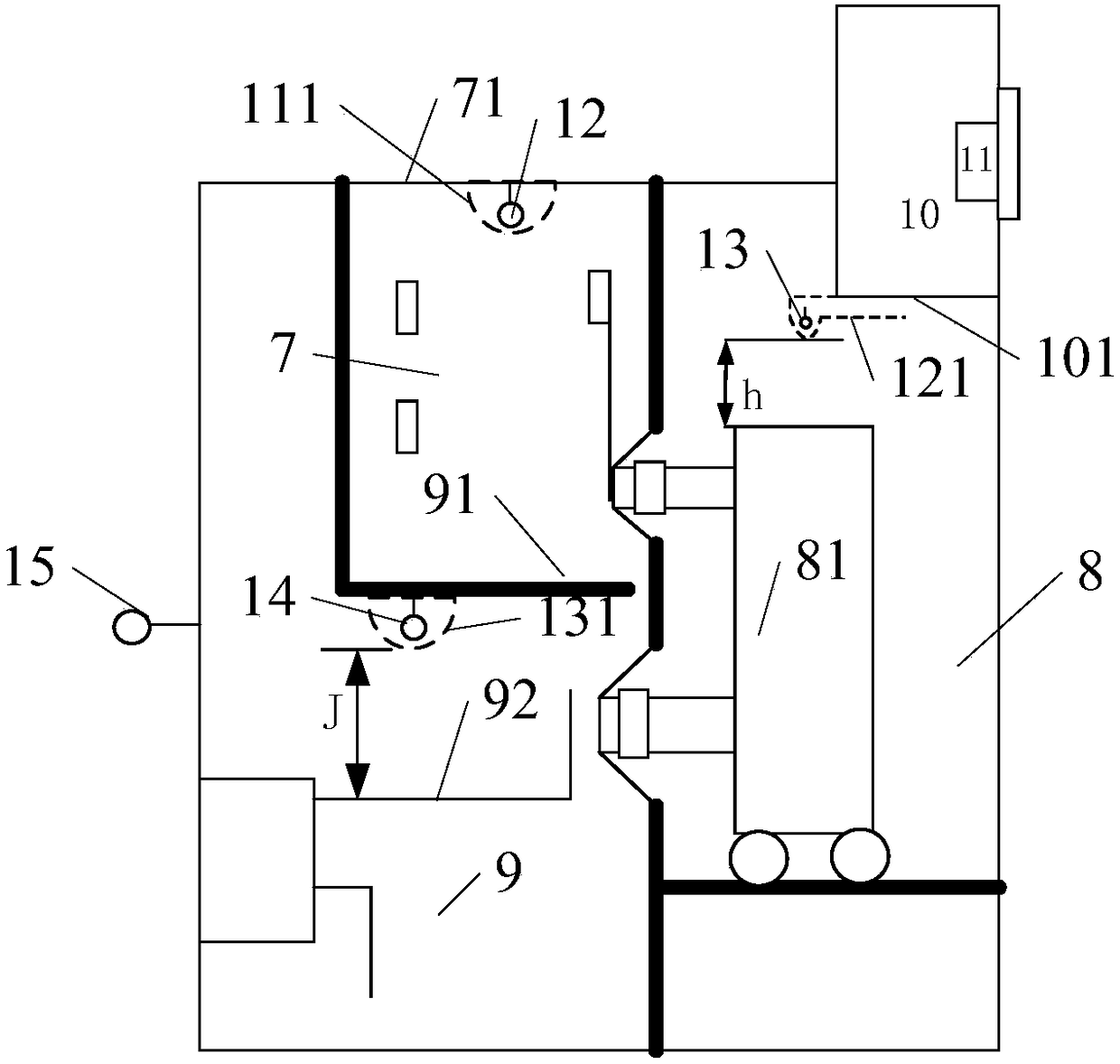

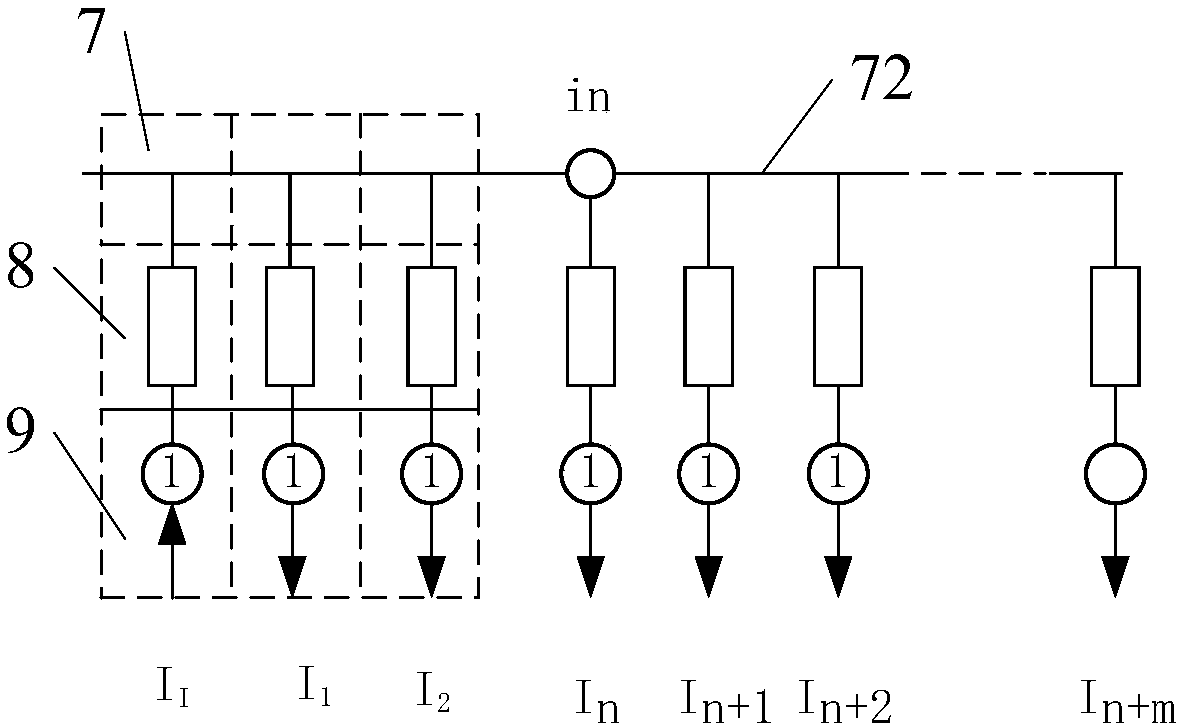

[0089] Example 1, please refer to figure 1 - Fig. 7 The thermal defect monitoring system of this embodiment includes: an information detection module 1, a communication module 2, and a data processing module 3; the information detection module 1 consists of a plurality of low-voltage sides respectively installed in each switch cabinet connected to the same group of busbars Composed of data acquisition units. Each low-voltage side data acquisition unit 11 includes 4 air temperature detection loops and 2 low-voltage side current detection loops to detect the ambient temperature, the air temperature of each compartment of the corresponding switchgear and the load current of these switchgears. Each data acquisition unit 11 is connected to the communication module 2 , and the communication module 2 is connected to the data processing module 3 . Ambient temperature sensor 15, compartment temperature sensors 12, 13, 14, current sensors 16, 17, these sensors are connected with the d...

Embodiment 2

[0106] Embodiment 2, the structure of this embodiment 2 and the embodiment 1 and the installation method in the switch cabinet are basically the same, the difference is that the aforementioned data acquisition unit 11 is replaced by the measurement and control device 4, and the measurement and control device 4 has the aforementioned thermal defect In addition to the temperature detection and current detection corresponding configurations of the low-voltage side data acquisition unit 11, there are also 1 gas detection circuit, 1 ultrasonic detection circuit, 1 photoelectric detection circuit and corresponding sensors 18, 19, 20; There are 2 circuit breaker closing and opening coil current detection circuits and current sensors 21, 22; and 2 auxiliary switch action signal detection circuits 23, 24; the measurement and control device 4 is also equipped with 2 circuits for controlling the entry and exit of the handcart of the circuit breaker The switch value output circuit 1DO, 2DO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius of curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com