Safety analysis method of main longitudinal beam of highway heavy-goods transport trailer

A technology for cargo transportation and safety analysis, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as complex solution process, cumbersome area calculation, and large amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

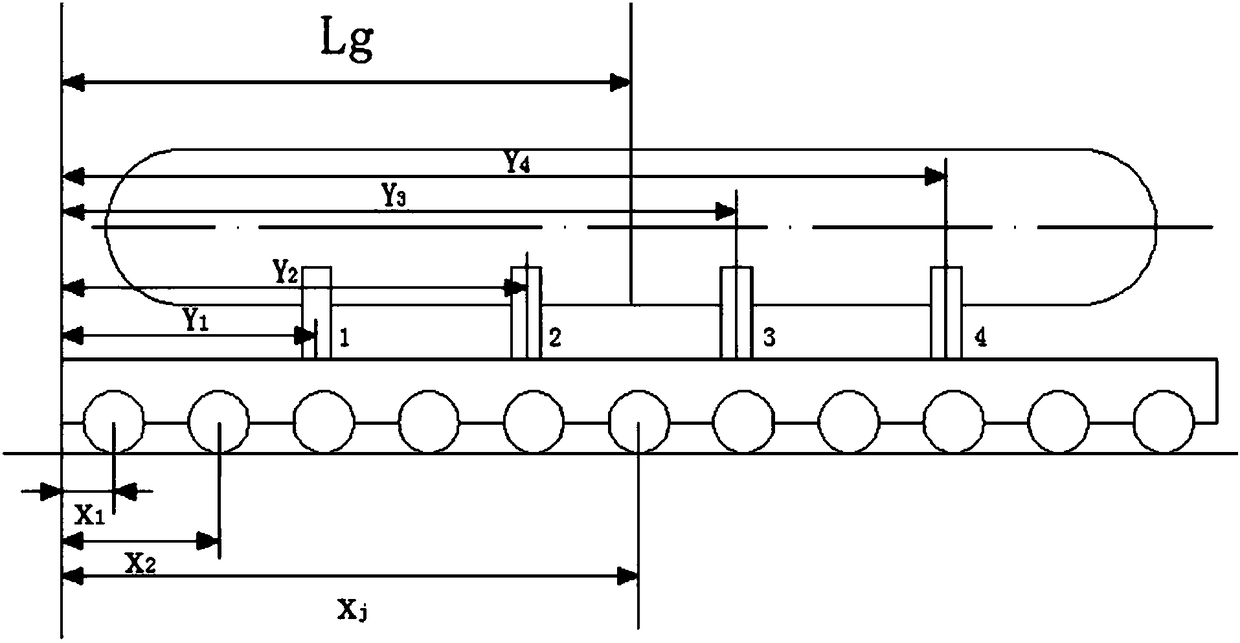

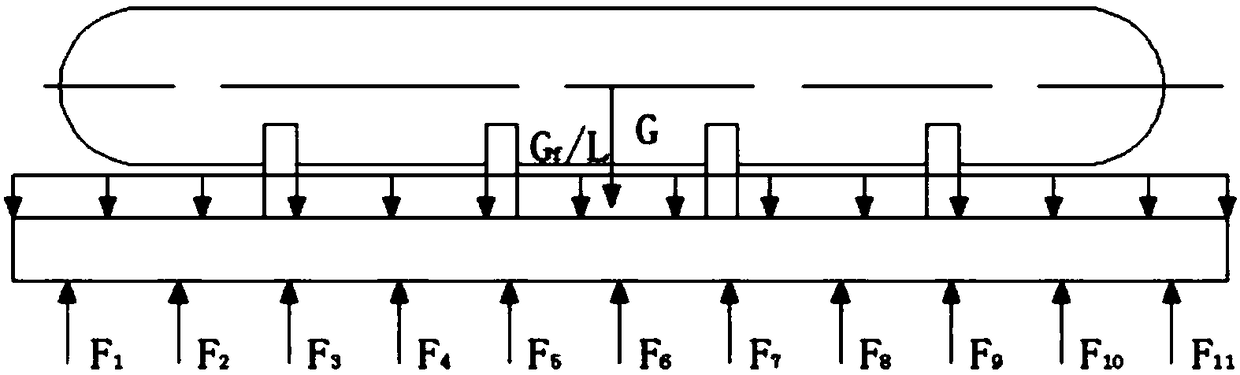

Embodiment 1

[0213] The number of axles of the trailer is 20, the wheelbase is 1500mm, there are 4 support beams, the mass of the cargo is G=510t, and the distances between the fulcrums of the cargo and the center of gravity of the cargo are 5000mm, 2000mm, -2000mm, -5000mm, (front positive and rear negative) , the center of gravity of the cargo is aligned with the longitudinal center of the trailer, and the weight of the frame is G f =80t. It is known that the cargo is supported by three points, the first two points are one point behind, the number of axes is I=13, J=7, and the moment of inertia of the main longitudinal beam of the trailer is I=6.58×10 9 mm 4 .

[0214] Find the support force F of each hydraulic shaft j ;

[0215] Know F from Formula 1 1 =……..=F 13 , F 14 =……=F 20

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com