Driving apparatus for washing machine

A driving device and a technology for a rotary driving device, which are applied in the directions of washing devices, electromechanical devices, transmission devices, etc., can solve the problems of increasing the number of parts, and achieve the effects of reducing the degree of wear, simplifying the structure, and simplifying the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

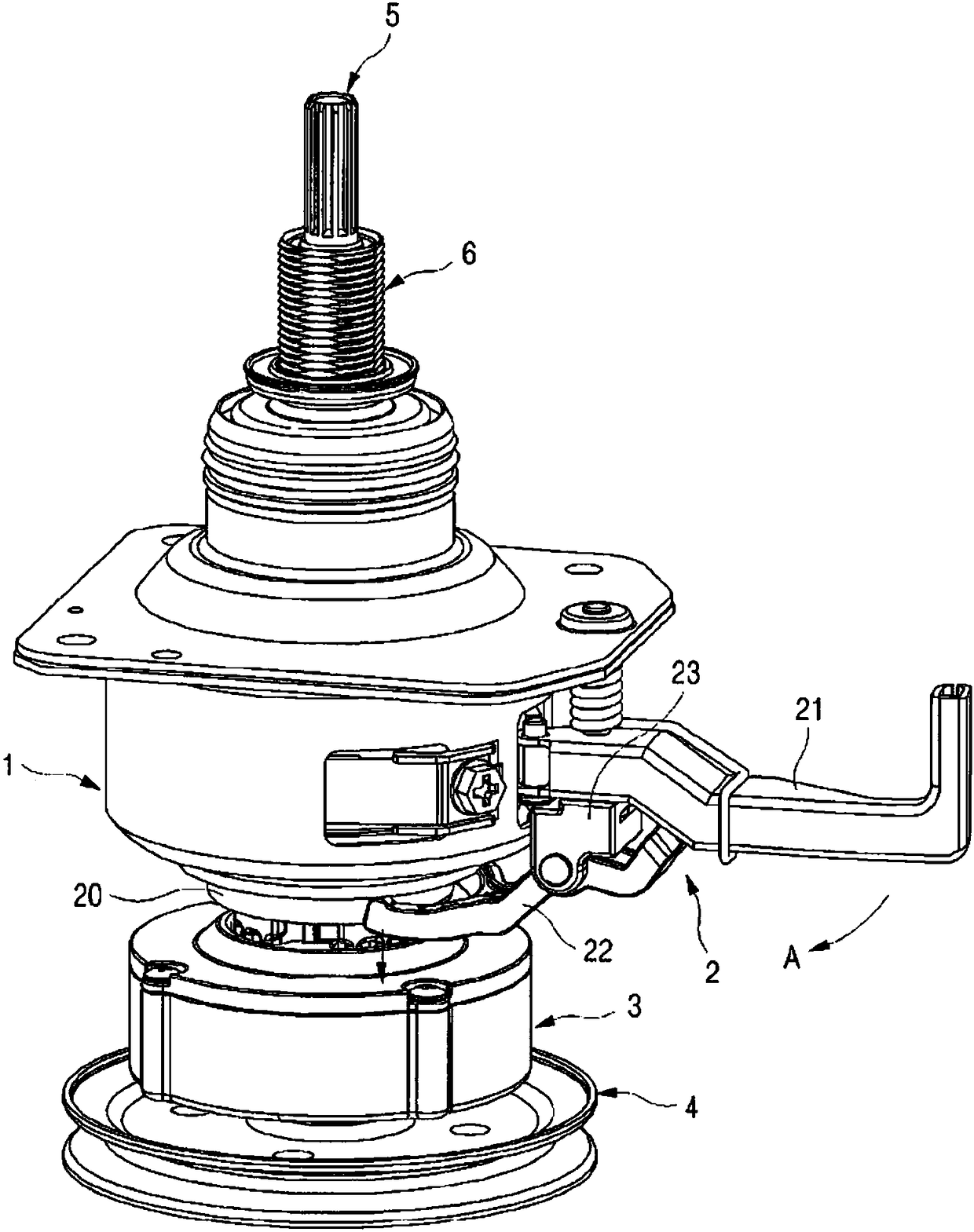

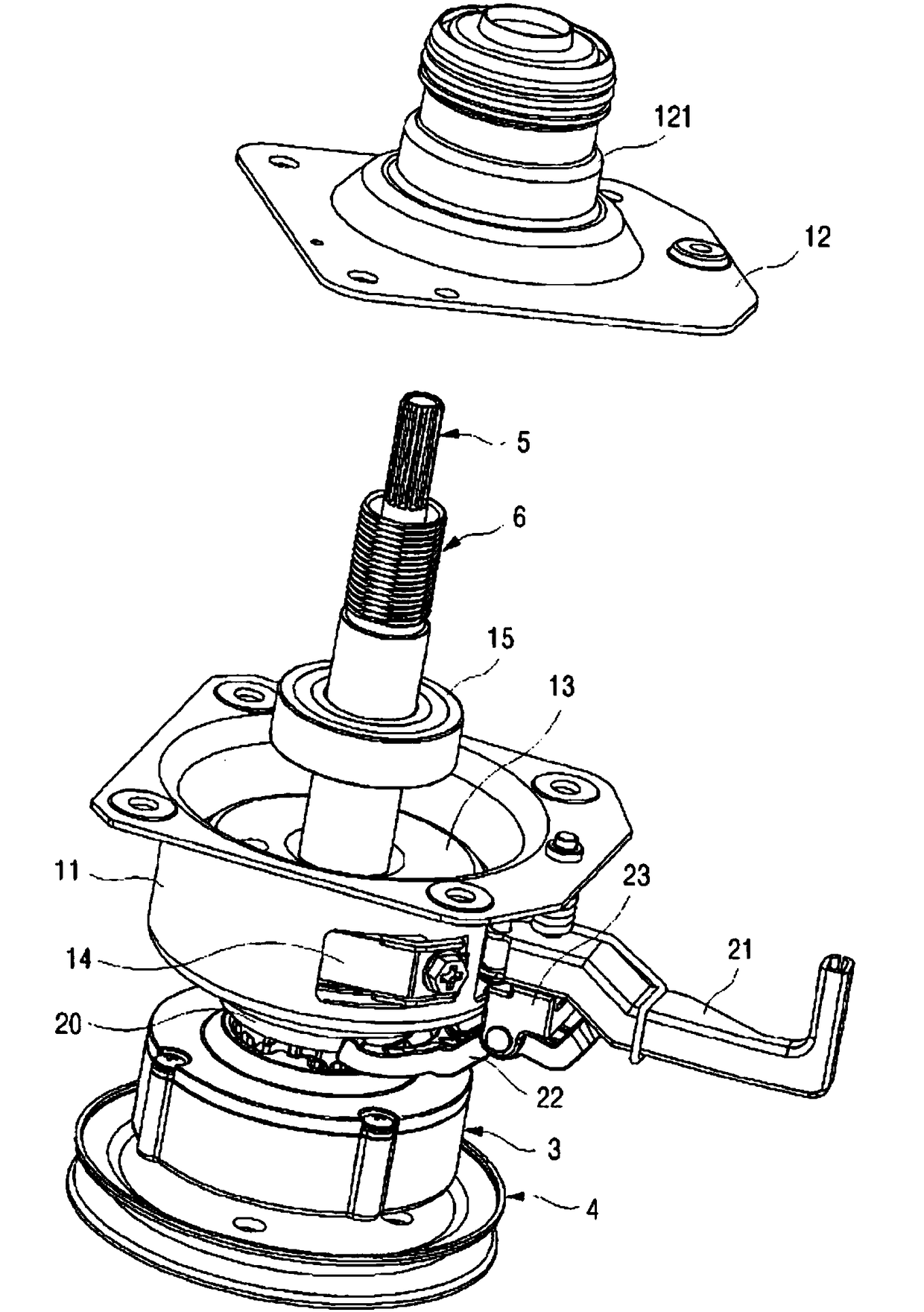

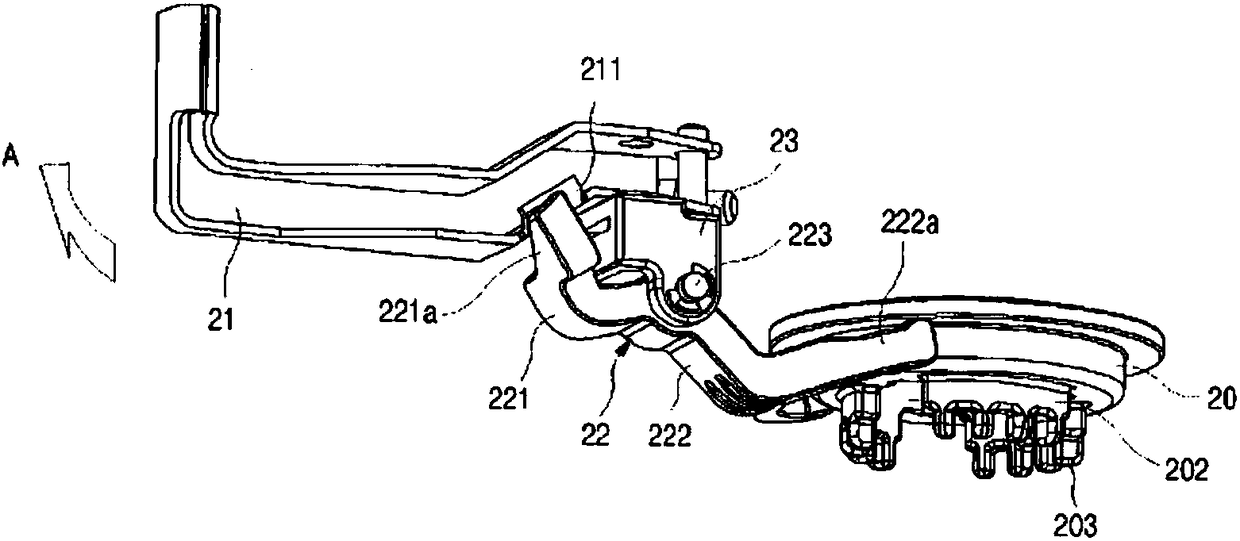

[0043] figure 1 It is a perspective view showing the driving device of the washing machine of the present invention, figure 2 It is an exploded perspective view showing the clutch main body 1 of the driving device of the washing machine of the present invention. Such as figure 1 with figure 2As shown, the driving device for a washing machine according to the present invention includes a clutch main body 1 , a clutch operating unit 2 , a speed reducer 3 , a rotation driving device 4 , a washing shaft 5 and a dehydration shaft 6 .

[0044] The clutch main body 1 includes a bottom case 11 and a top case 12 , and a brake drum 13 is located in a space inside the bottom case 11 . The brake drum 13 prohibits or stops the rotation of the spin shaft 6 when the brake band is pulled by the operation of the brake lever 21 . According to the present invention, since the speed reducer 3 is located outside the clutch body 1 and separated from the brake drum 13, the structure of the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com