Baby bed

A crib and bed frame technology, applied in the field of cribs, can solve the problems of high cost, time-consuming production, and large packaging volume, and achieve the effects of convenient storage, reduced production costs, and simple disassembly methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

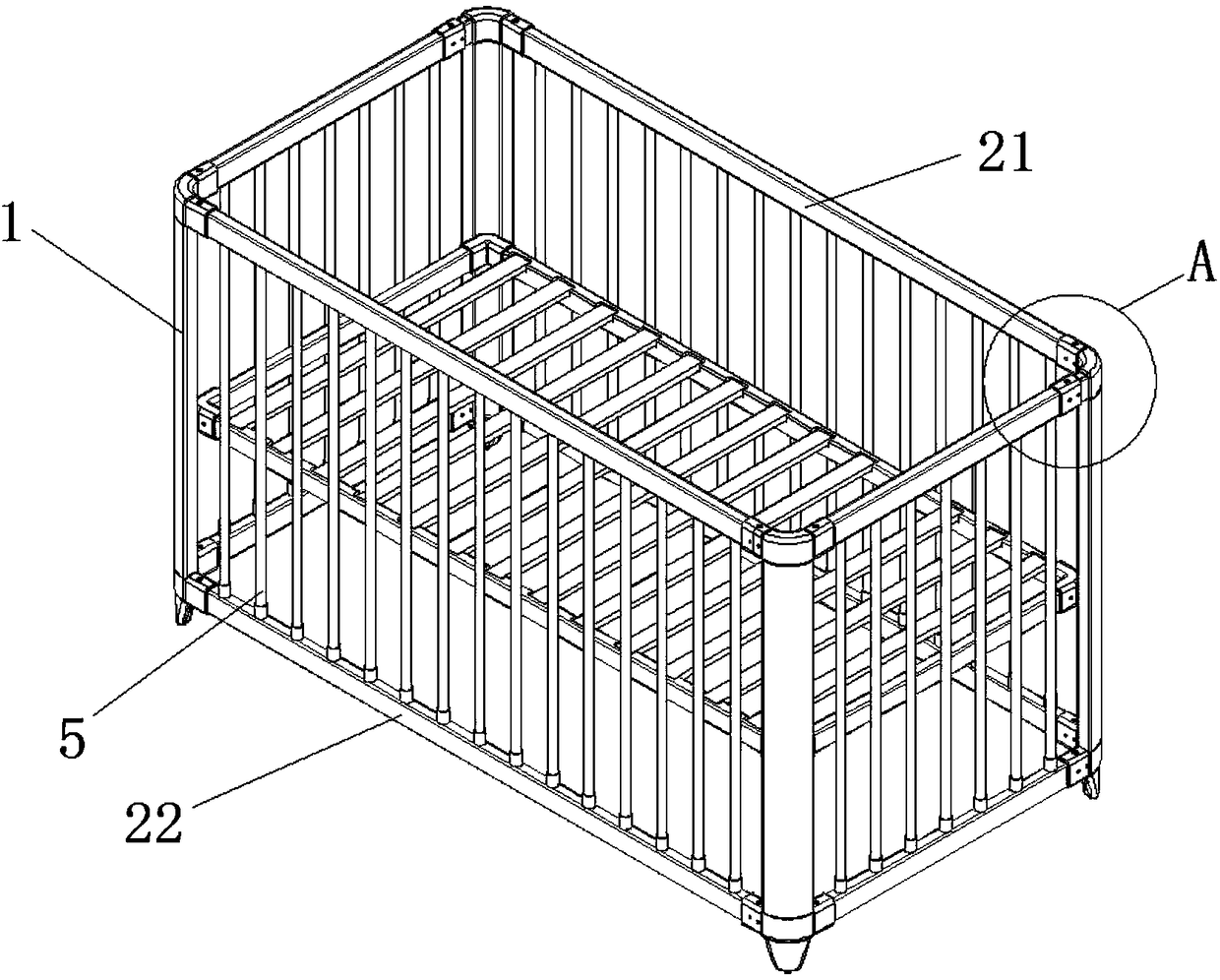

[0034] a crib such as Figure 1 to Figure 6 As shown, it includes a bed frame composed of a column 1 and a rail 2 and a bed board arranged in the bed frame. The connecting end of the column 1 and the connecting end of the rail 2 are connected through the first self-locking structure. piece 3 is connected.

[0035] A crib based on the above-mentioned structure has a simple structure. When assembling, it is only necessary to connect the upright column 1 and the horizontal rail 2 through the first connecting piece 3 to form a bed frame, and place the bed board in the bed frame to complete the baby bed. Assembling the bed, this assembling method saves the production time of the crib and improves the production efficiency; and in the assembling process of the crib, there is no need to use spare parts such as glue or screws, which greatly reduces the production cost of the crib.

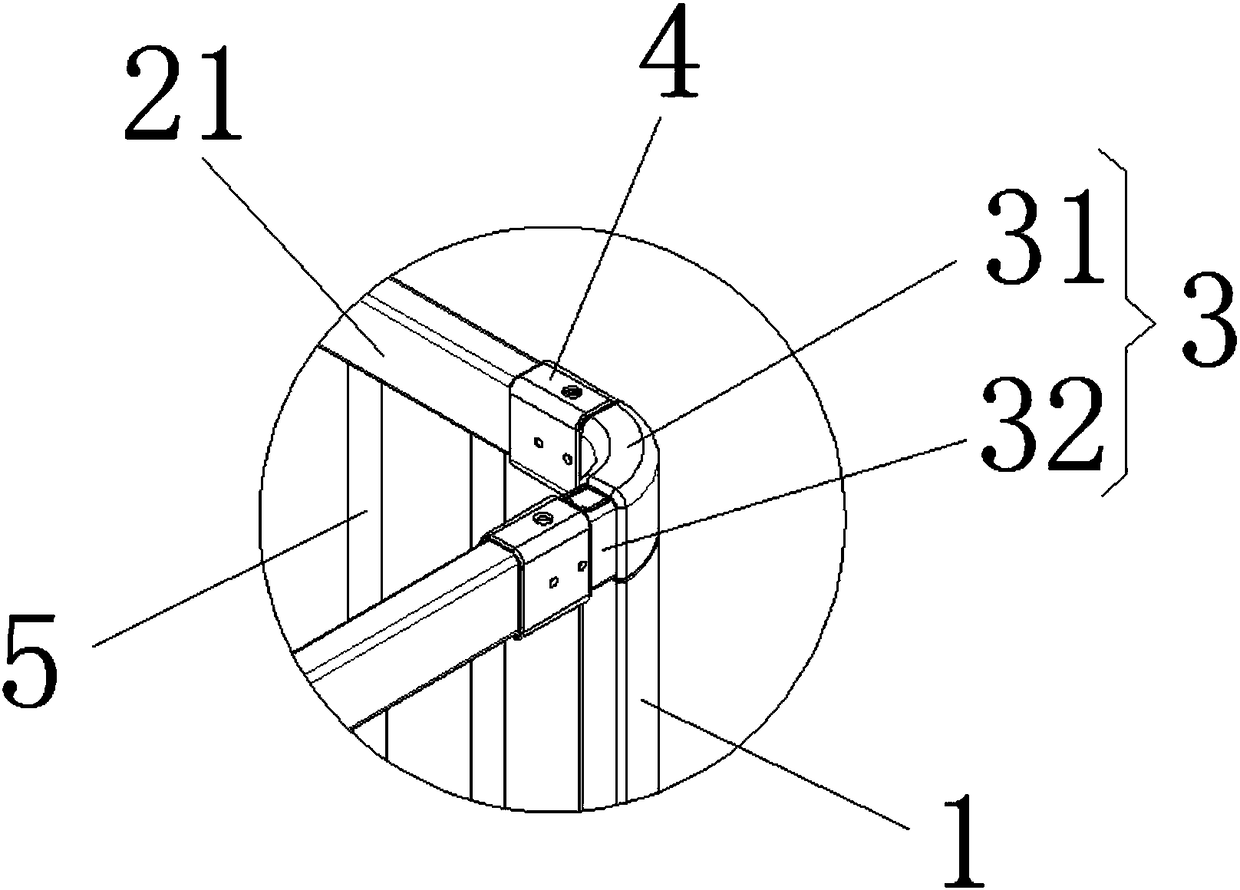

[0036] Optimally, the first connector 3 includes a column connector 31 and a rail connector 32, the co...

Embodiment 2

[0049] like Figure 1 to Figure 6 As shown, for further optimization in the above-mentioned embodiment, the rail connector 32 is provided with an elastic piece, and the locking sleeve 4 is provided with a fixing hole. When the column 1 and the rail 2 pass through the column connector 31 and the rail connector 32 When the connection is fixed, the locking sleeve 4 can be slid, so that the locking sleeve 4 fixes the connecting end of the column connector 31 and the rail connector 32, and the position of the locking sleeve 4 is fixed by the cooperation of the shrapnel and the fixing hole. , thereby further increasing the safety of the crib.

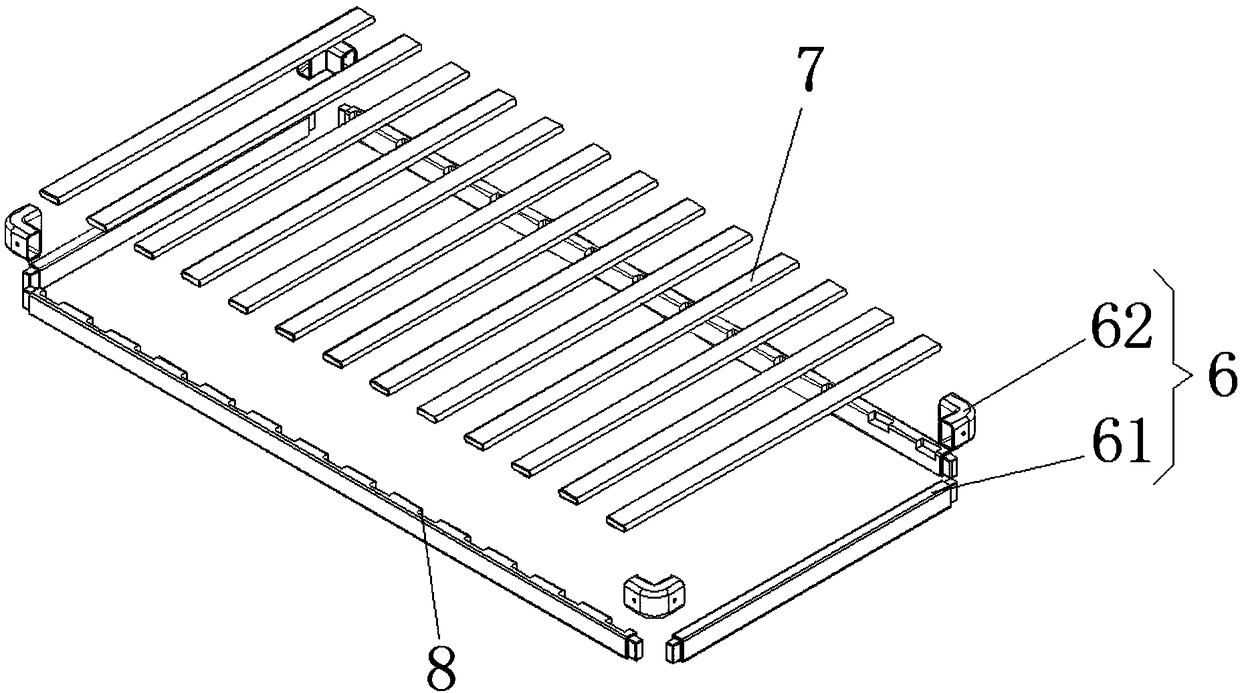

[0050] Optimally, the frame 6 includes a side bar 61 and a second connecting piece 62 connecting the side bar 61 ; the connection end of the second connecting piece 62 and the side bar 61 is provided with a slot for inserting the side bar 61 .

[0051] Specifically, four side strips 61 and four second connectors 62 are selected to form a qua...

Embodiment 3

[0056] like Figure 1 to Figure 7 As shown, as a further optimization of Embodiment 1 and Embodiment 2, the bed frame of the crib is a quadrangular bed frame; when in use, one side of the bed frame can be removed, and the height of the bed board can be adjusted to match the other. The height of the bed is the same, and then the crib is spliced together with other beds to increase the range of activities of the baby.

[0057] Optimally, the bottom end of the column 1 is provided with pulleys to facilitate the movement of the crib.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap