Manufacturing method of rapid hemostasis device

A manufacturing method and rapid technology, which are applied in the directions of non-active ingredients, such as medical preparations, pharmaceutical formulations, and pharmaceutical science, to achieve the effects of high preparation efficiency, improved therapeutic effect, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

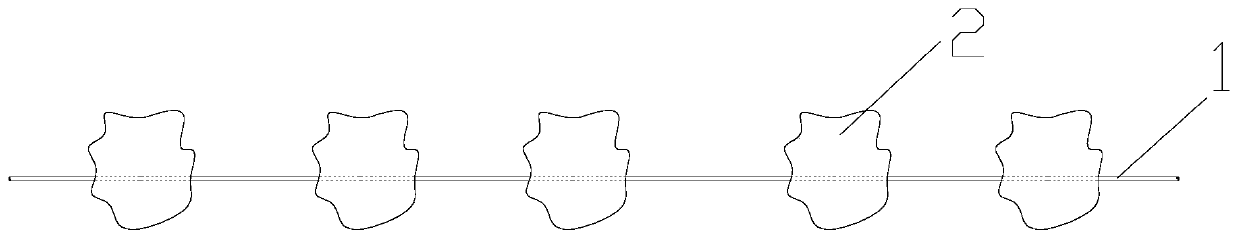

[0050] Such as Figure 1-2 As shown, a method of manufacturing a rapid hemostasis device according to the present invention includes the following steps in sequence:

[0051] Step 1: Fabrication of the hemostatic block unit chain: Cut the prepared hemostatic block into multiple hemostatic block units 2, connect the hemostatic block units 2 in series with a connecting line 1, and make the hemostatic block unit 2 on the connecting line 1 Distributed at upper intervals to form a hemostatic block unit chain; repeat this process to prepare multiple hemostatic block unit chains;

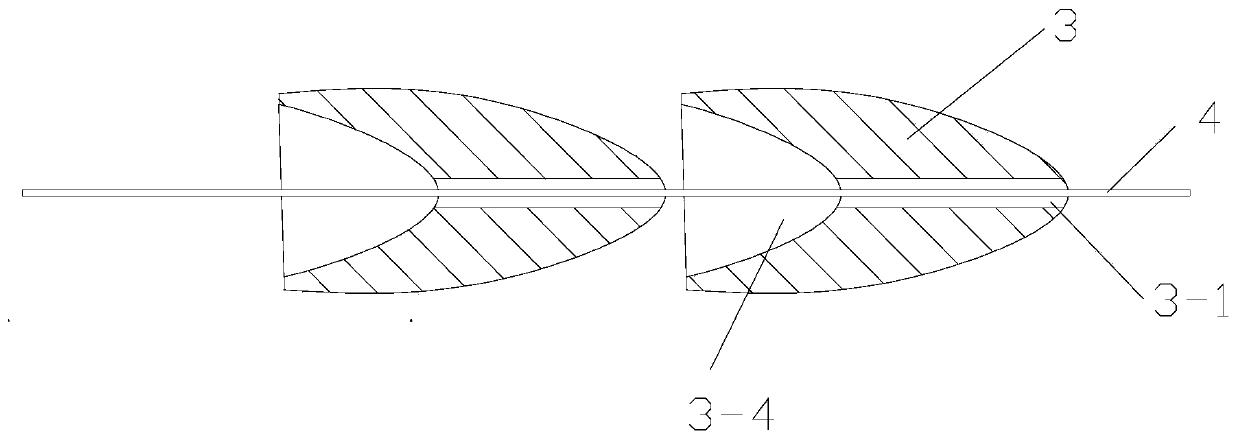

[0052] Step 2: Compression: Compress each hemostatic block unit chain into an agglomerate 3, and make each agglomerate 3 have a channel 3-1 through itself through the mold during compression;

[0053] Step 3: Connection of agglomerates: using a flexible guide wire 4 to sequentially pass through the channel 3-1 of each agglomerate 3 to connect multiple agglomerates 3 into a string.

[0054] Each agglomera...

Embodiment 2

[0057] Such as figure 1 , 3 As shown, a method of manufacturing a rapid hemostasis device according to the present invention includes the following steps in sequence:

[0058]Step 1: Fabrication of the hemostatic block unit chain: Cut the prepared hemostatic block into multiple hemostatic block units 2, connect the hemostatic block units 2 in series with a connecting line 1, and make the hemostatic block unit 2 on the connecting line 1 Distributed at upper intervals to form a hemostatic block unit chain; repeat this process to prepare multiple hemostatic block unit chains;

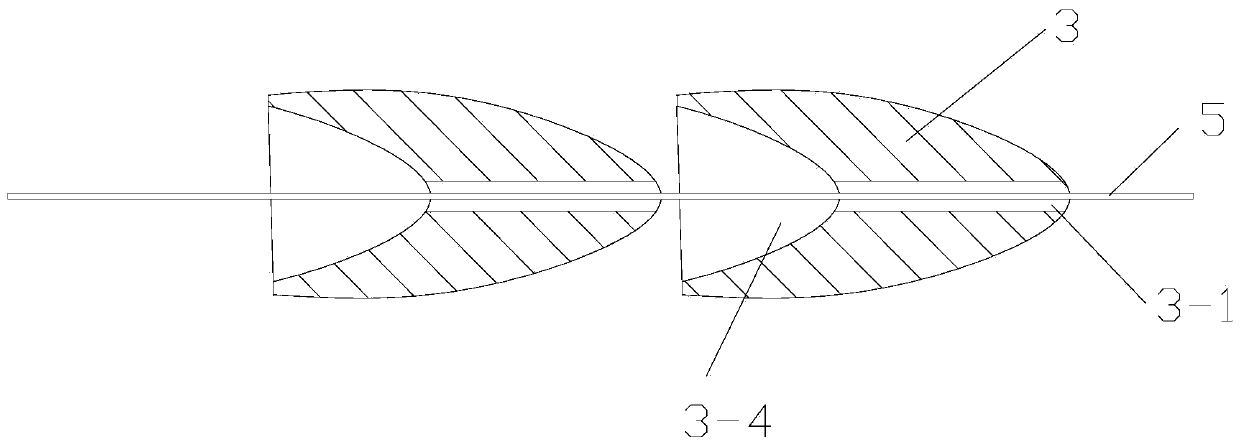

[0059] Step 2: Compression: Compress each hemostatic block unit chain into an agglomerate 3, and make each agglomerate 3 have a channel 3-1 through itself through the mold during compression;

[0060] Step 3: Connection of agglomerates: using a hollow flexible connecting tube 5 to sequentially pass through the channel 3-1 of each agglomerate 3 to connect a plurality of agglomerates 3 into a string.

[0...

Embodiment 3

[0064] Such as figure 1 , 4 As shown, a method of manufacturing a rapid hemostasis device according to the present invention includes the following steps in sequence:

[0065] Step 1: Fabrication of the hemostatic block unit chain: Cut the prepared hemostatic block into multiple hemostatic block units 2, connect the hemostatic block units 2 in series with a connecting line 1, and make the hemostatic block unit 2 on the connecting line 1 Distributed at upper intervals to form a hemostatic block unit chain; repeat this process to prepare multiple hemostatic block unit chains;

[0066] Step 2: Compression: Compress each hemostatic block unit chain into an agglomerate 3, and make each agglomerate 3 have a channel 3-1 through itself through the mold during compression;

[0067] Step 3: Connection of agglomerates: using a hollow flexible connecting tube 5 to sequentially pass through the channel 3-1 of each agglomerate 3 to connect a plurality of agglomerates 3 into a string.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com