Portable moving platform of laser equipment and application thereof

A mobile platform and laser equipment technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of slow moving speed of the transmission mechanism, affecting the moving speed of the transmission mechanism, and inability to adapt to various operating requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

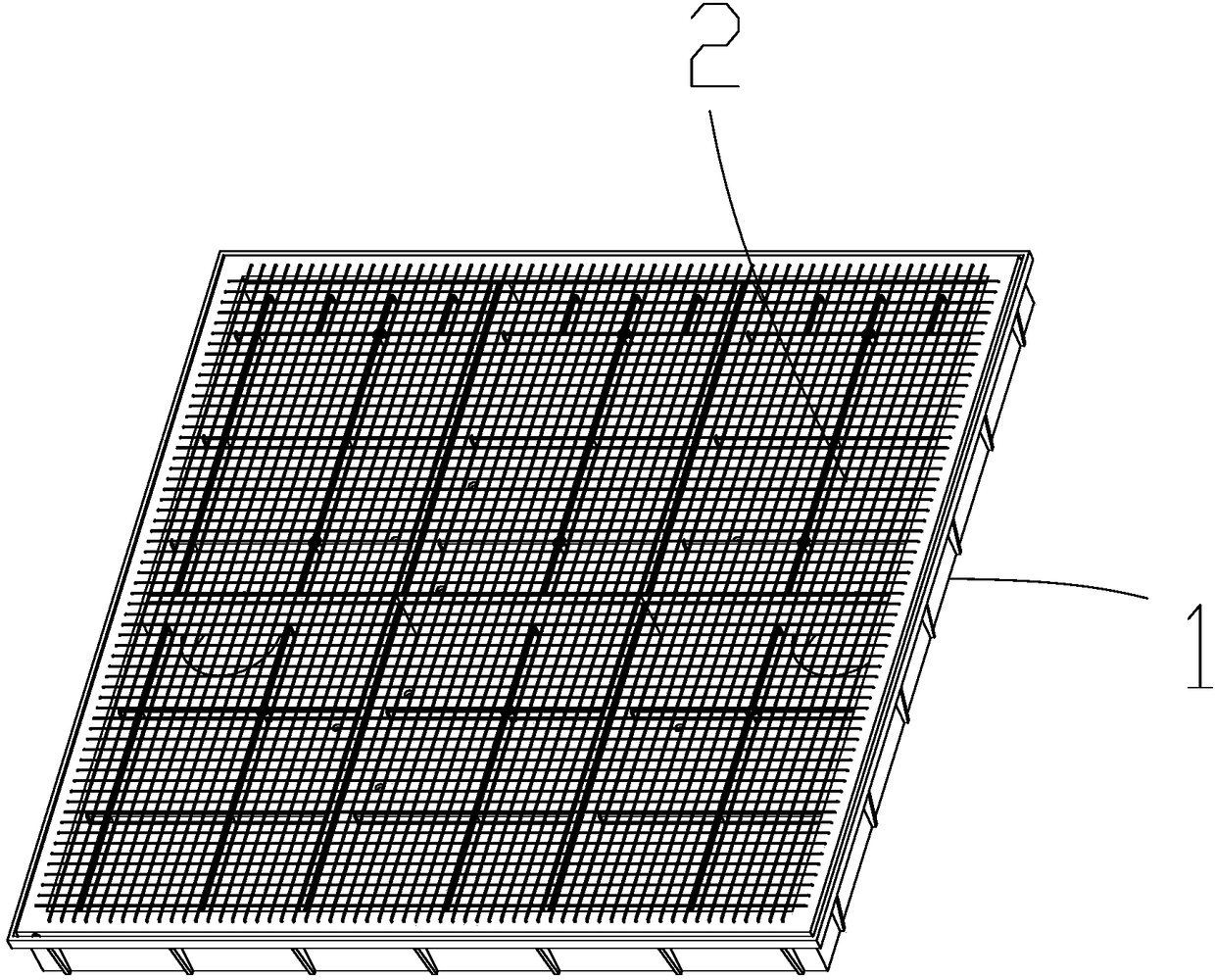

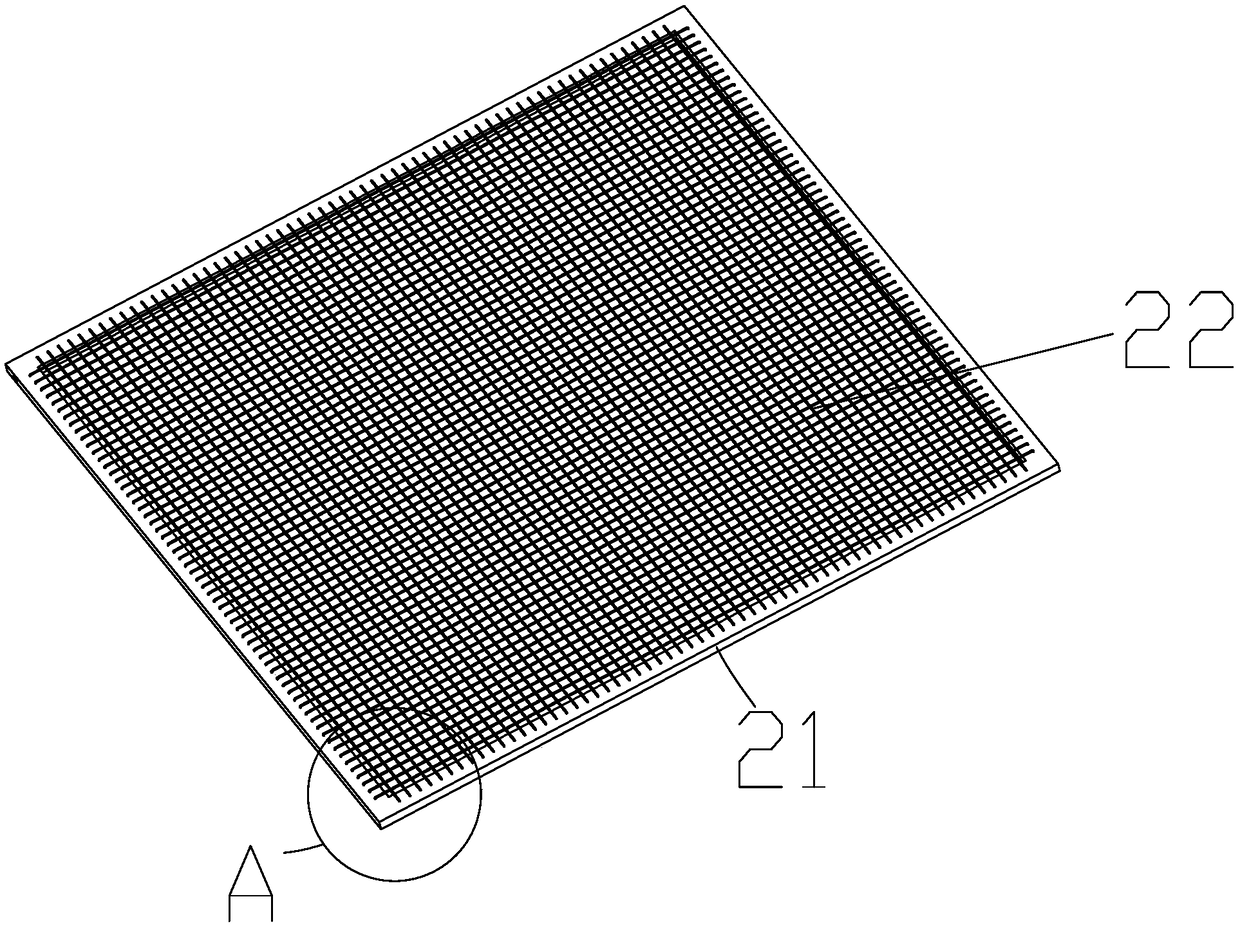

[0037] Such as Figures 1 to 8 As shown, this embodiment provides a portable mobile platform for flat marking materials, including a plastic chassis 1, and the plastic chassis 1 is provided with a placement tray 2 covering the upper surface of the plastic chassis 1, and the placement tray 2 It includes a wire frame 21 and a carrying wire 22, the wire frame 21 is fixedly arranged on the plastic chassis 1, and a plurality of the carrying wires 2 are equidistantly arranged on one side of the wire frame 21 in the form of a mesh On the surface, one end of the plastic chassis 1 is open, and the opening is connected to the placement tray 2 , and the peripheral edge of the opening extends upwards to form a surrounding groove 11 wrapping the outer edge of the wire frame 21 .

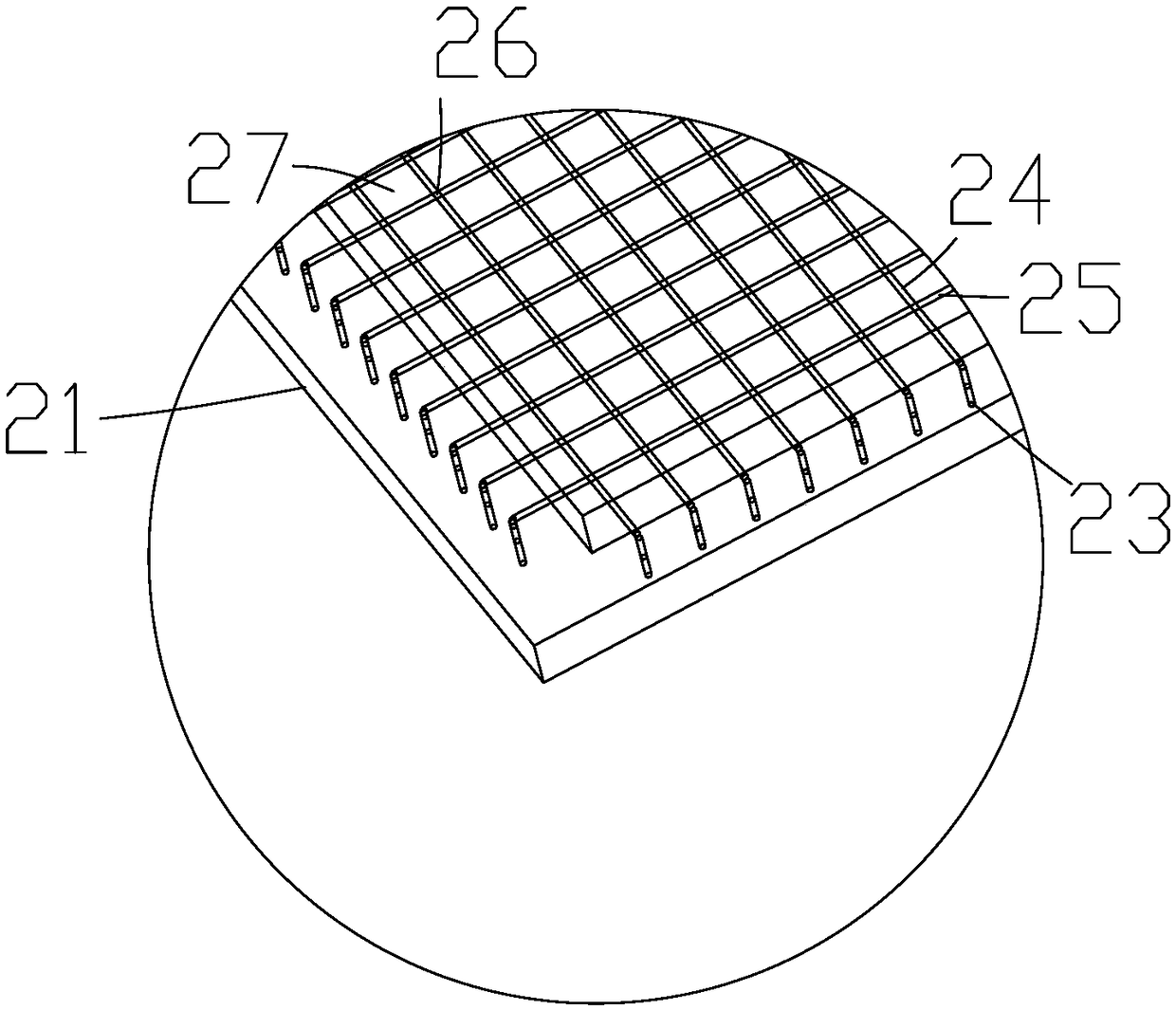

[0038] The wire frame 21 is a regular quadrilateral, and the wire frame 21 is provided with a wire hole 23 corresponding to the position of the carrying wire 22. above the wireframe 21.

[0039] Both ends of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com