Track frame mounting turnover device

A technology of turning device and crawler frame, applied in workpiece clamping device, metal processing, metal processing equipment and other directions, can solve the problems of unsatisfactory production efficiency and labor intensity, and achieve convenient turning and installation process, flexible and convenient use, The effect of improving quality reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

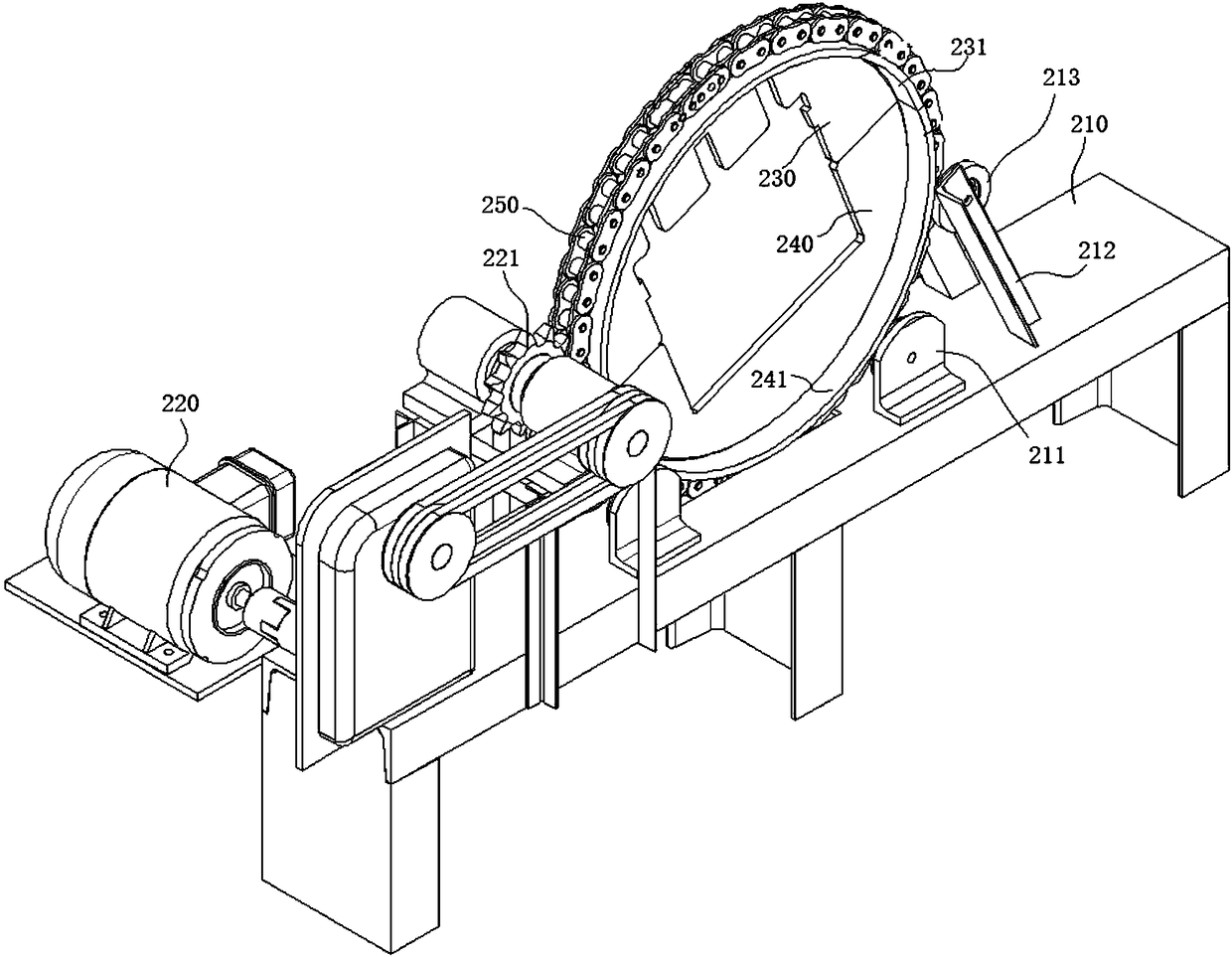

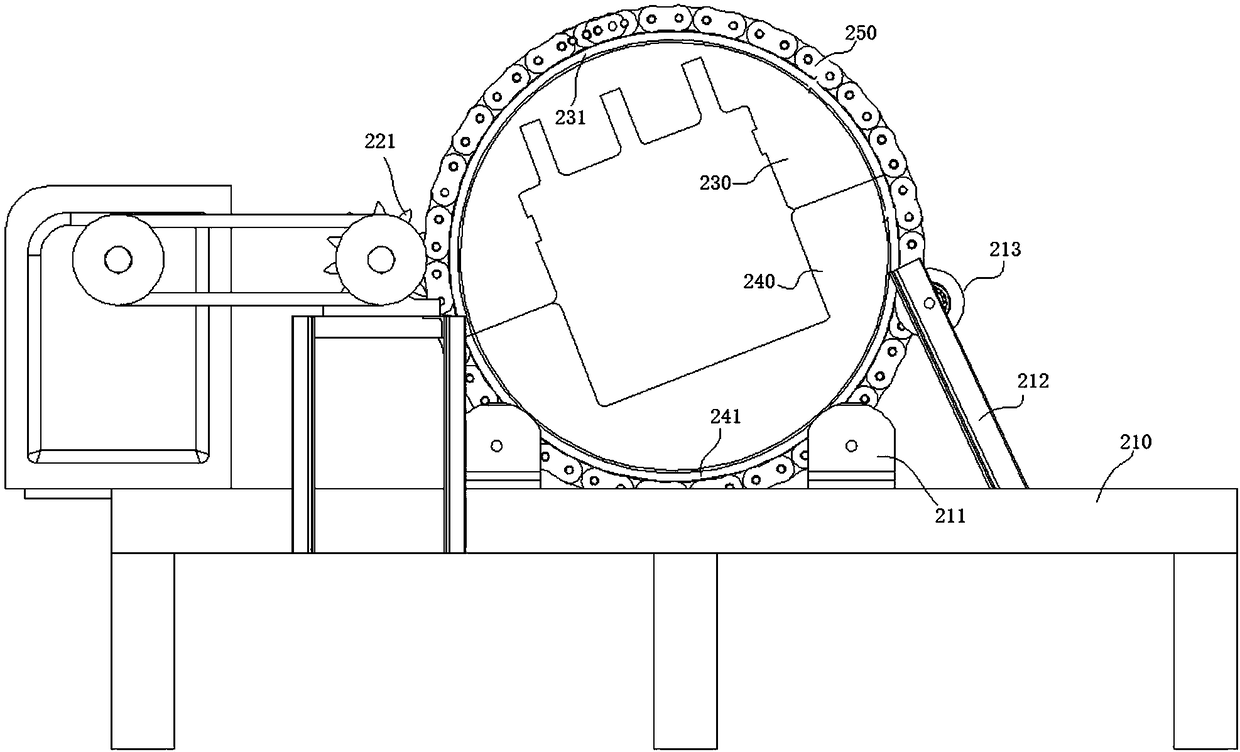

[0048] Such as Figure 1-Figure 10 As shown, a crawler frame installation and overturning device of this embodiment includes active bearing units 200 and driven bearing units 300 arranged at both ends of the crawler frame 100; wherein the active bearing unit 200 includes a power unit 220, a main upper card wheel 230 and The main lower card wheel 240, the main upper card wheel 230 and the main lower card wheel 240 cooperate up and down to form a circular wheel-shaped structure. The main lower card wheel 240 is supported by the main support assembly and can rotate flexibly on the main support assembly. Both the upper card wheel 230 and the main lower card wheel 240 are provided with engagement grooves matching the ends of the track frame 100, and the circumferential side walls of the main upper card wheel 230 and the main lower card wheel 240 are provided with transmission chains. 250 , the transmission chain 250 meshes with the transmission gear 221 on the power unit 220 . The...

Embodiment 2

[0056] A crawler frame installation turning device of this embodiment has the same basic structure as that of Embodiment 1. Furthermore, in this embodiment, a main upper ring wall 231 is arranged around the circumferential side wall of the main upper card wheel 230, and the main upper ring The wall 231 surrounds the outer circumference of the main upper card wheel 230 and extends to both sides. The circumferential side wall of the main upper card wheel 230 is located in the middle of the main upper ring wall 231. The circumferential side wall of the main lower card wheel 240 is surrounded by The main lower ring wall 241, similarly, the main lower ring wall 241 surrounds the outer periphery of the main lower card wheel 240 and extends to both sides, the circumferential side wall of the main lower card wheel 240 is located in the middle of the main lower ring wall 241, and the transmission chain 250 are respectively arranged on the main upper ring wall 231 and the main lower ring...

Embodiment 3

[0059] A kind of crawler frame installation turnover device of this embodiment, the basic structure is the same as embodiment 2, further, such as image 3 with Figure 4 As shown, the main support assembly in this embodiment includes two sets of main bottom brackets symmetrically arranged on both sides of the bottom of the main lower card wheel 240, and each group of main bottom brackets includes main bottom supports distributed on the front and rear sides of the main lower card wheel 240 211, the inner sides of the main bottom supports 211 on both sides are respectively provided with main bottom support wheels, and the fastening screws pass through the main bottom supports 211 and the main bottom support wheels on both sides in turn and are fastened by nuts, the main bottom supports on both sides The wheels are correspondingly located on both sides of the transmission chain 250 , and are in contact with the circumferential side walls of the main lower card wheel 240 , that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com