Fusing mechanism of full automatic fuse machine

A hot-melt machine and fully automatic technology, applied in the field of sewing equipment, can solve the problems of low degree of automation, low overall pass rate, and inability to efficiently complete the assembly of the entire mechanism of the skylight, so as to achieve easy replacement, easy control, and avoid wire drawing or coking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

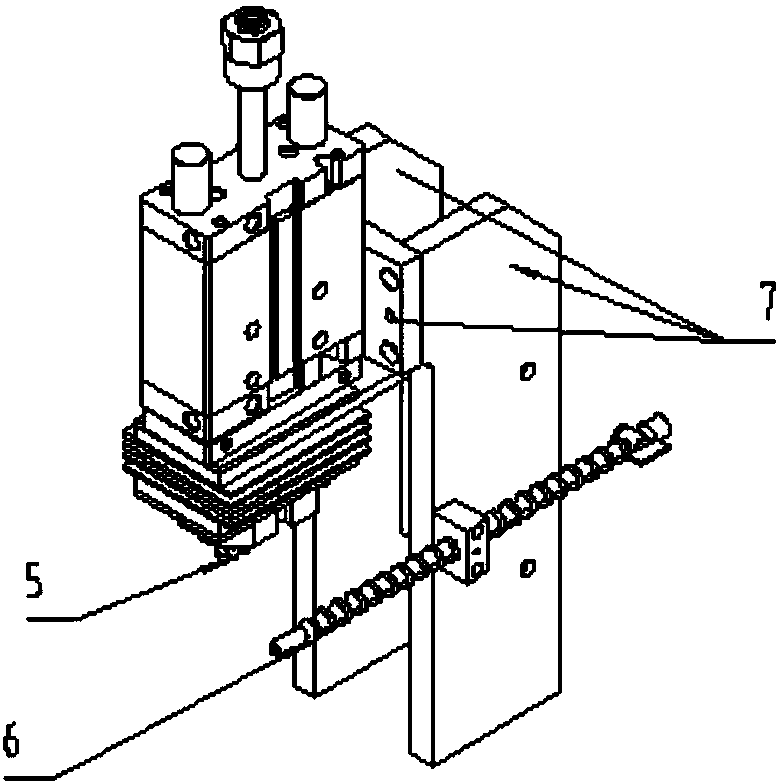

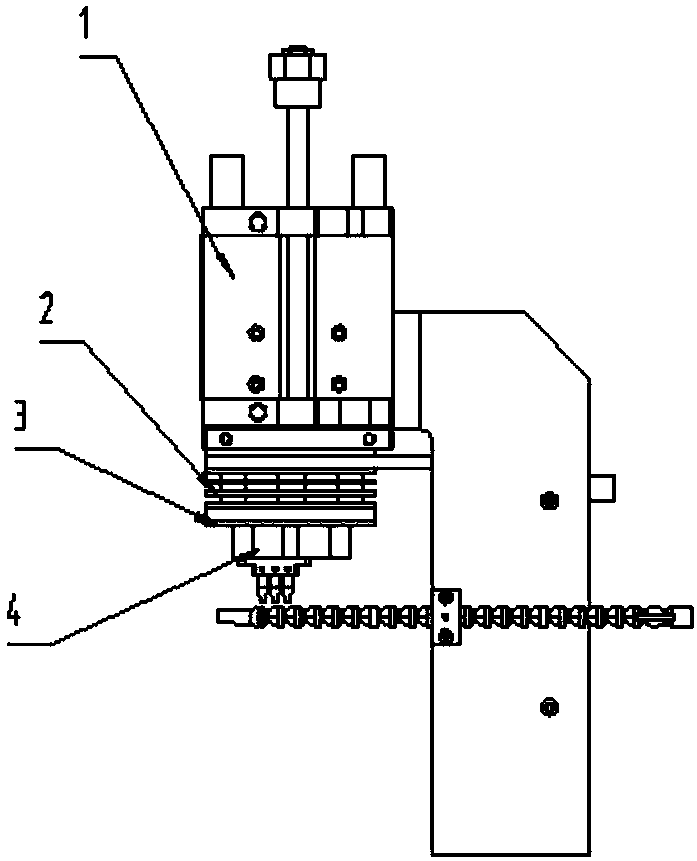

[0012] The present invention is further described below in conjunction with the accompanying drawings: a fully automatic hot-melt machine hot-melt mechanism assembly includes: hot-melt cylinder 1, heat dissipation mechanism 2, heat shield 3, hot-melt head mounting plate 4, hot-melt head 5, blowing pipe 6. The hot-melt mechanism installation plate 7, the hot-melt cylinder 1 is fixedly connected with the hot-melt mechanism installation plate 7, the heat dissipation mechanism 2 is located at the bottom of the hot-melt cylinder 1, and the hot-melt head installation plate 7 is fixed on the lower heat insulation board 3, The hot-melt head 5 is installed on the hot-melt head mounting plate 4, and the hot-melt head mounting plate 7 has two holes, one hole is used for installing a heating rod, and the other hole is used for installing a sensor for sensing temperature.

[0013] The use process of the hot-melt mechanism of a fully automatic hot-melt machine is: when the hot-melt workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com