Working table convenient for automobile oil sludge model production

A sludge model and workbench technology, which is applied to workbenches, processing models, manufacturing tools, etc., can solve problems such as increased cost, sludge is easy to fall on the ground, and poor use efficiency of sludge, so as to ensure plasticity, use efficiency, Effects that are easy to modify

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

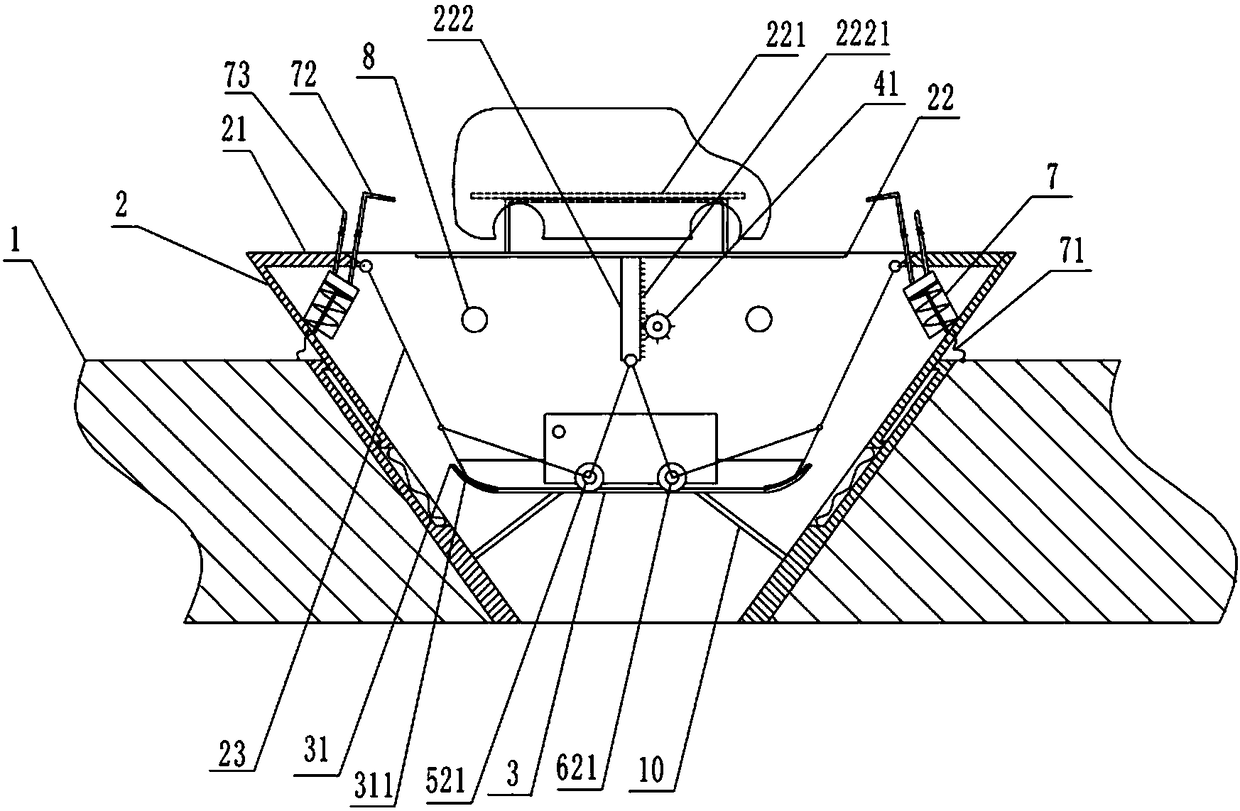

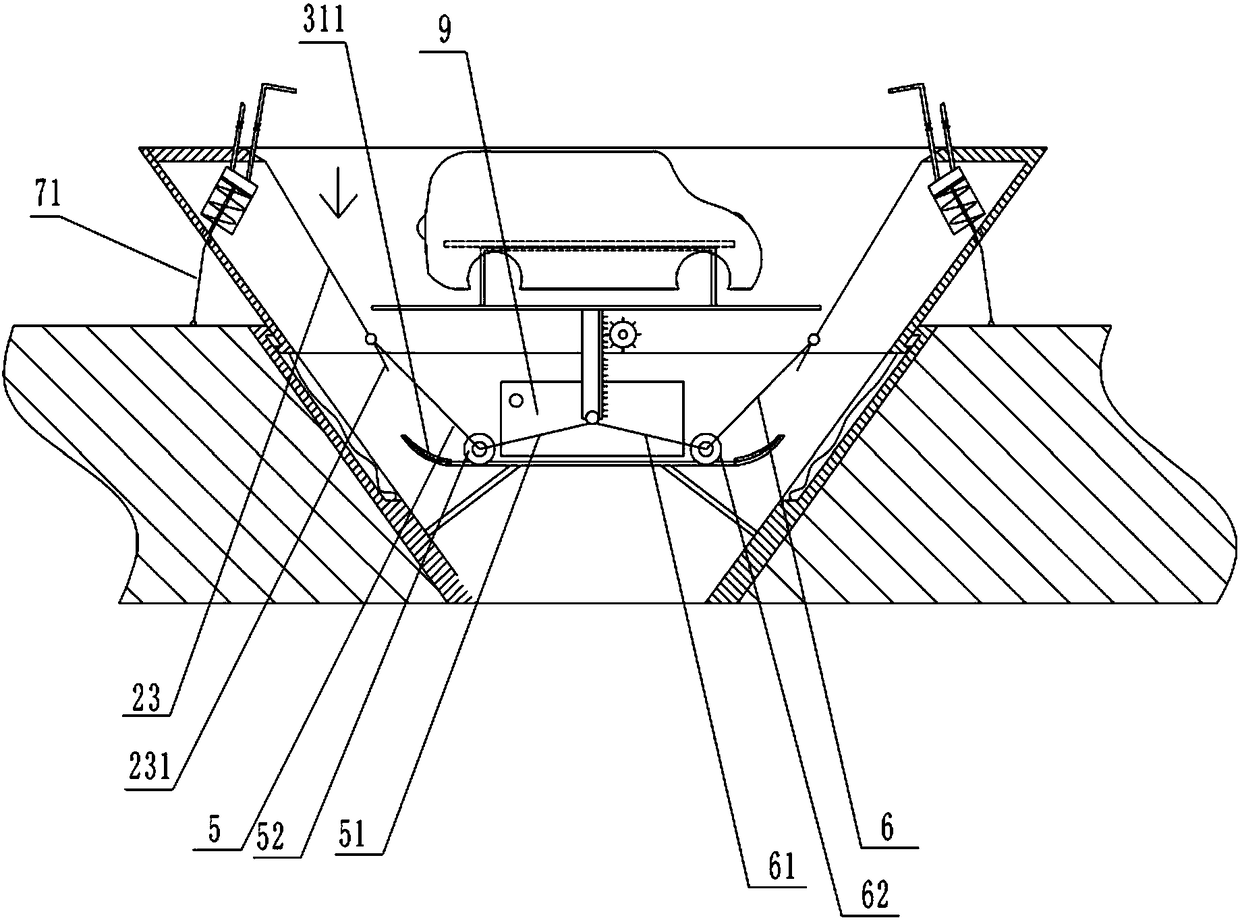

[0024] The reference signs in the drawings of the description include: workbench body 1, sliding cover 2, flat flange 21, support plate 22, support frame 221, support rod 222, rack 2221, support slant plate 23, second contact point 231 , heating plate 3, arc convex edge 31, first contact 311, gear 41, first swing rod 5, first push rod 51, first roller 52, first rotating shaft 521, second swing rod 6, second Push rod 61, second roller 62, second rotating shaft 621, suction cylinder 7, stay wire 71, suction pipe 72, air outlet pipe 73, hot air pipe 8, pick-and-place mouth 9, support platform 10.

[0025] Such as figure 1 with figure 2 Shown, in order to achieve the above object, basic scheme of the present invention is as follows:

[0026] A workbench for making automobile clay models, comprising a workbench body 1, a processing chamber is provided on the workbench body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com