Steering and suspension system

A technology of suspension system and steering gear, which is applied in the direction of suspension, elastic suspension, steering mechanism, etc. It can solve the problems of unreliable reliability, practical use, high technical difficulty, etc., and achieve improved dynamic characteristics and good ride feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

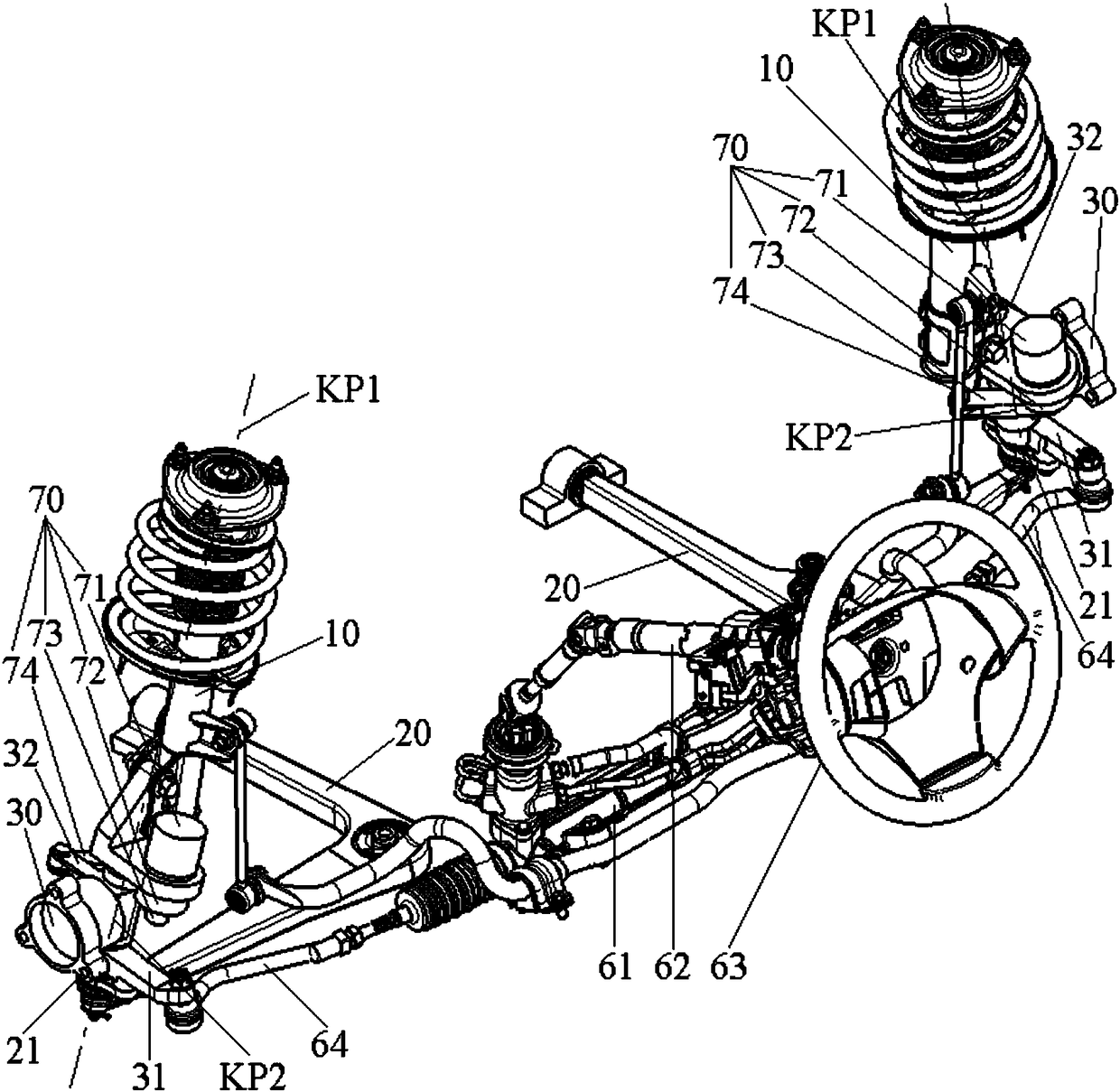

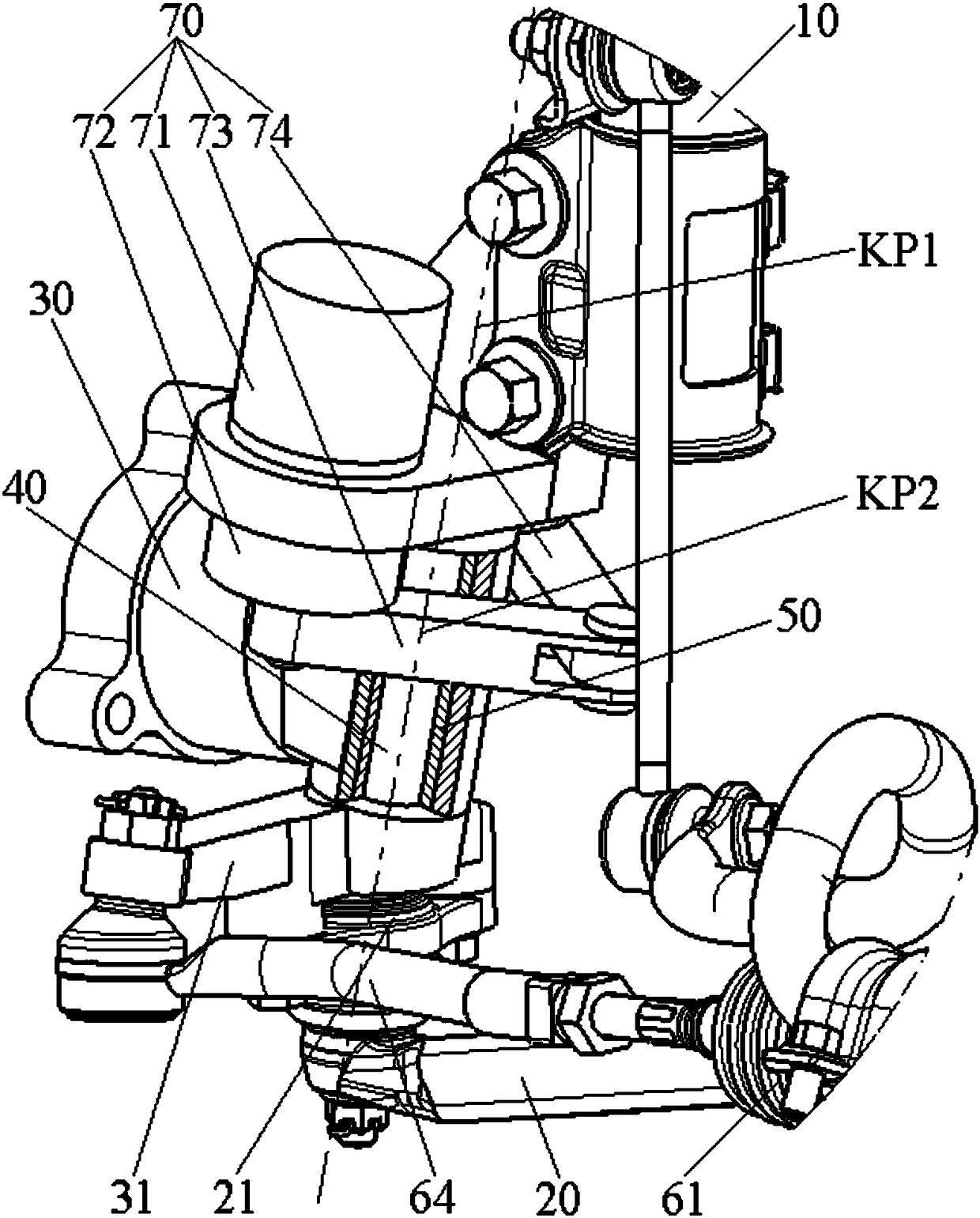

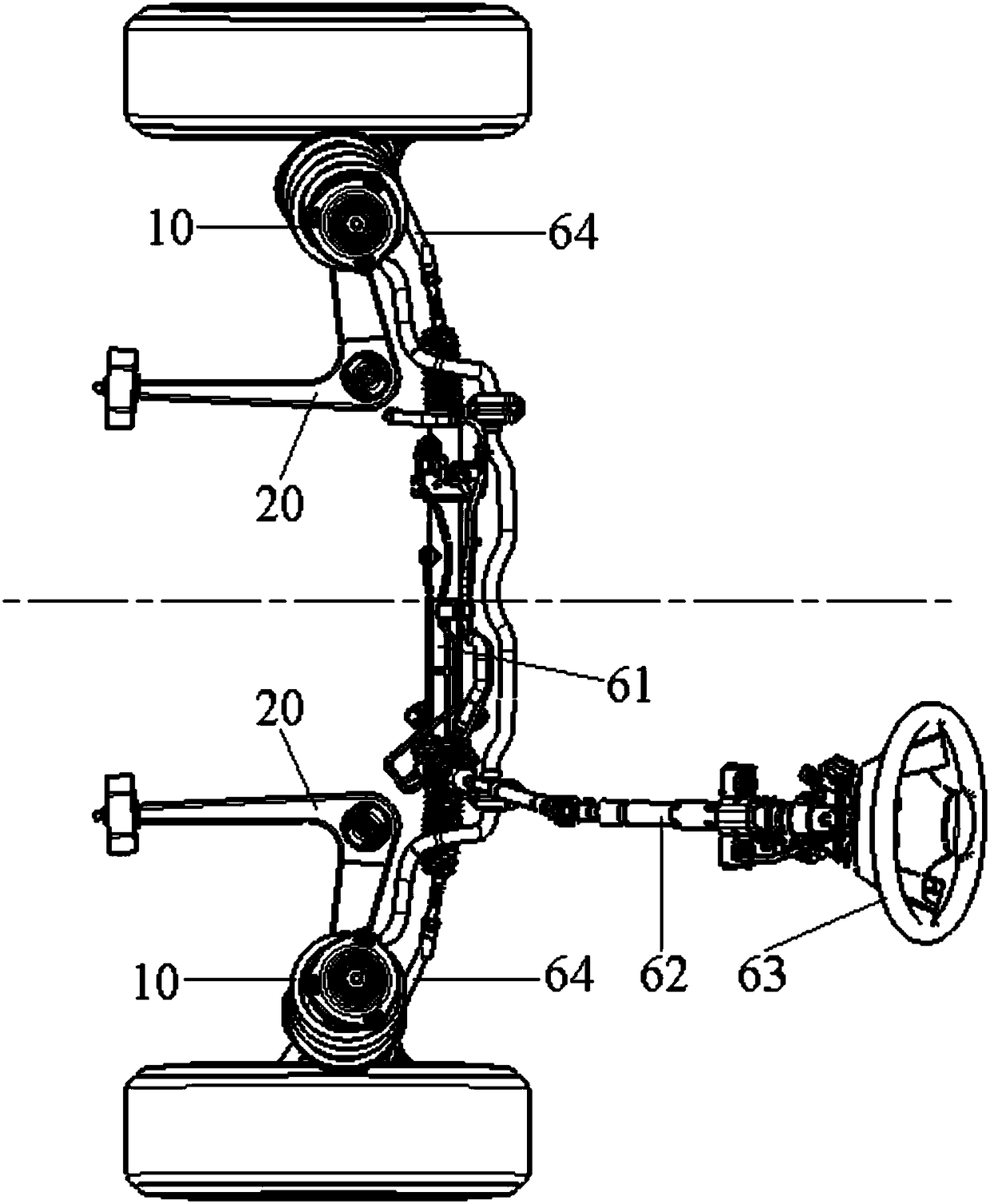

[0078] see Figure 1~6 As shown, in the first specific embodiment of the present invention, the steering and suspension system of the present invention includes: a spring strut 10, a pin shaft 40, a lower guide ball joint 21, a swing arm 20, a wheel bracket 30, a first Steering knuckle arm 31, steering tie rod 64, steering gear 61, wheel steering gear 70; wherein,

[0079] The lower end of the spring strut 10 is fixedly connected with the upper end of the pin shaft 40, and the lower end of the pin shaft 40 is connected with the swing arm 20 through the lower guide ball joint 21; The line forms the first kingpin axis KP1; the pin axis of the pin shaft 40 is the second kingpin axis KP2, and the second kingpin axis KP2 coincides with the first kingpin axis KP1;

[0080] One end of the first steering knuckle arm 31 is fixedly connected to the pin shaft 40 or the spring strut 10, and the other end of the first steering knuckle arm 31 is connected with the steering gear 61 through ...

Embodiment 2

[0099] refer to Figure 7 and Figure 8 , in the second specific embodiment of the present invention, the steering and suspension system of the present invention includes: a spring strut 10, an upper guide element 51, a lower guide ball joint 21, a swing arm 20, a wheel bracket 30, a first steering Knuckle arm 31, steering tie rod 64, steering gear 61 and wheel steering gear 70; wherein,

[0100] The lower end of the spring strut 10 is connected with the upper end of the wheel bracket 30 through the upper guide element 51, the lower end of the wheel bracket 30 is connected with the swing arm 20 through the lower guide ball joint 21, the upper fulcrum of the spring strut 10 is connected with the lower guide ball The line connecting the center of the hinge 21 forms the first kingpin axis KP1; the upper guide element 51 and the lower guide ball hinge 21 form the second kingpin axis KP2;

[0101] One end of the first steering knuckle arm 31 is fixedly connected to the spring str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com