Method for reducing fiber breaking rate in pulping process using waste paper for papermaking

A waste paper papermaking and fiber breaking technology, which is applied in papermaking, fiber raw materials, textiles and papermaking, etc., can solve the problems of large return flow in the wire part, low fiber utilization rate, and low production efficiency, achieving less damage, good quality, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

[0028] The method for reducing the fiber breakage rate in the refining process of using waste paper to make paper is to pump the material to be refined into a refiner for refining treatment, including the following steps:

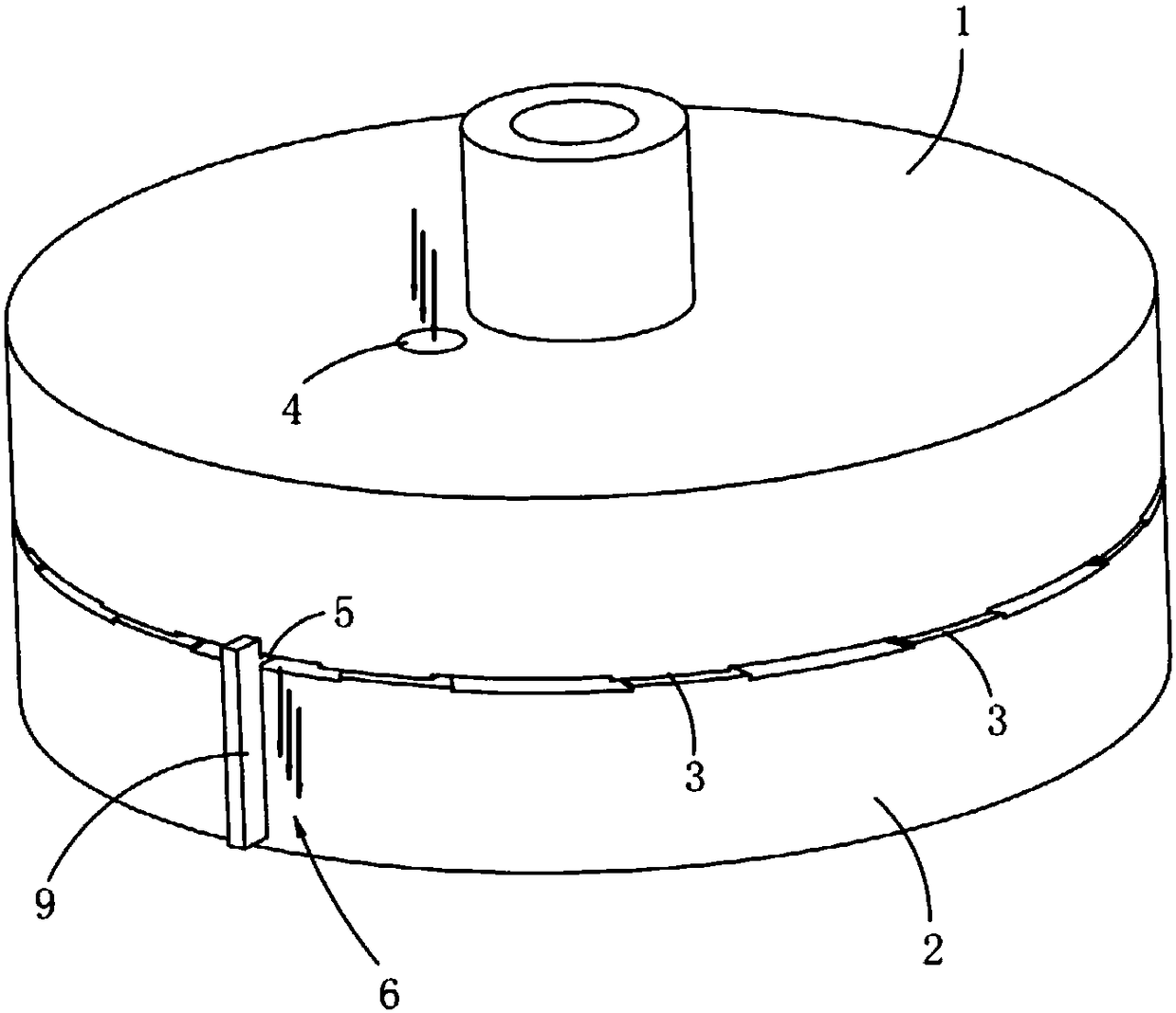

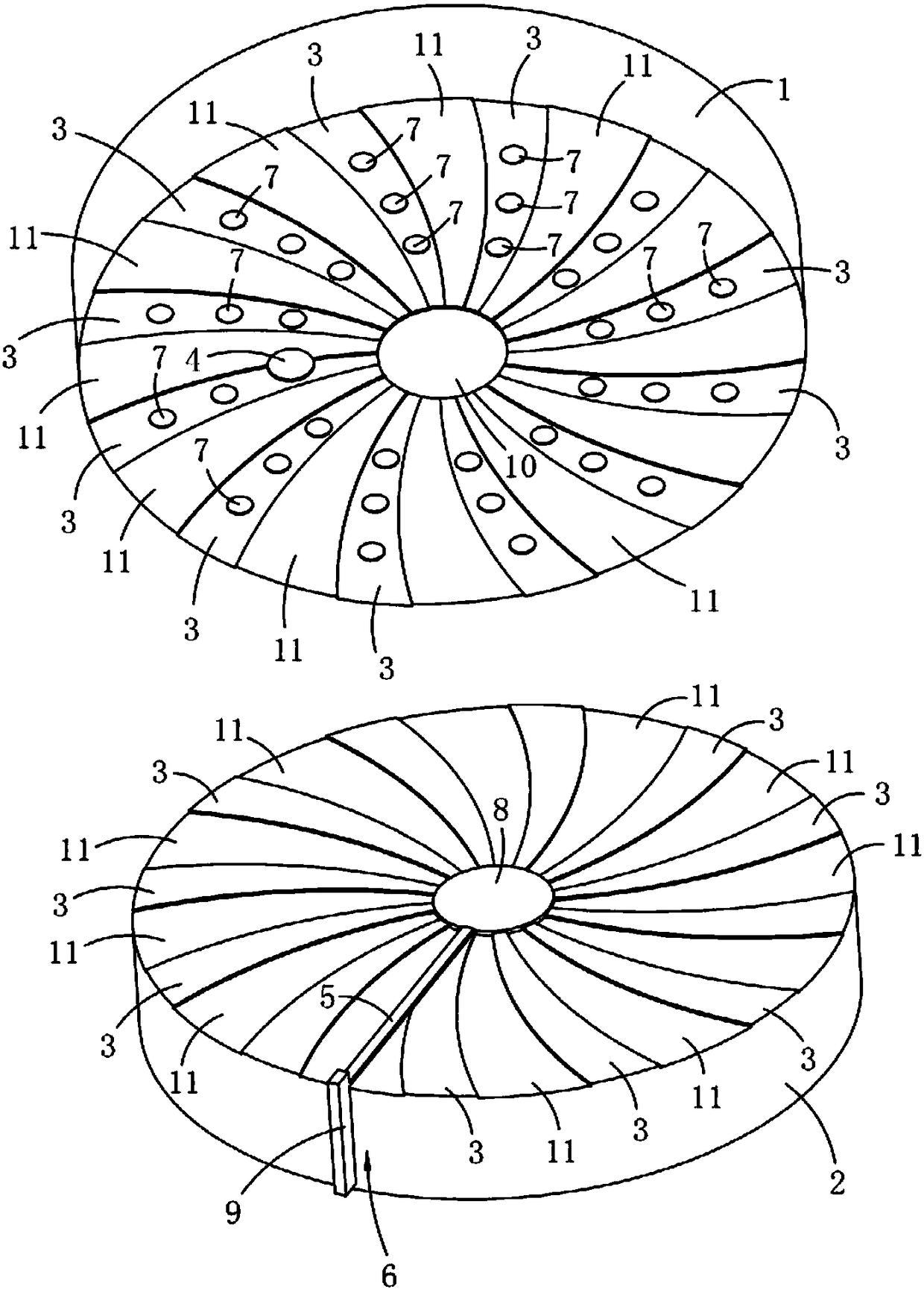

[0029] Refining by rotating the lower grinding disc 2 installed in the refiner, refining by matching the upper grinding disc 1 fixed in the refiner with the lower grinding disc 2, the opposite surface of the upper grinding disc 1 and the lower grinding disc 2 is set as the refining surface A refining area is formed between the upper and lower refining surfaces of the upper grinding disc 1 and the lower grinding disc 2, the upper grinding disc 1 with a diameter of 1.0-1.8 meters is selected, the lower grinding disc 2 with a diameter of 1.0-1.8 meters is selected, and the upper Grinding disc 1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com