Large-aperture valve flow rate test system pipeline bracket device

A valve flow and pipeline support technology, applied in the direction of pipeline supports, hoses, pipes, etc., can solve the problems of difficult adjustment of support height, large frictional resistance, and difficulty in ensuring pipeline stability, so as to improve installation stability and improve The effect of lifting balance and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

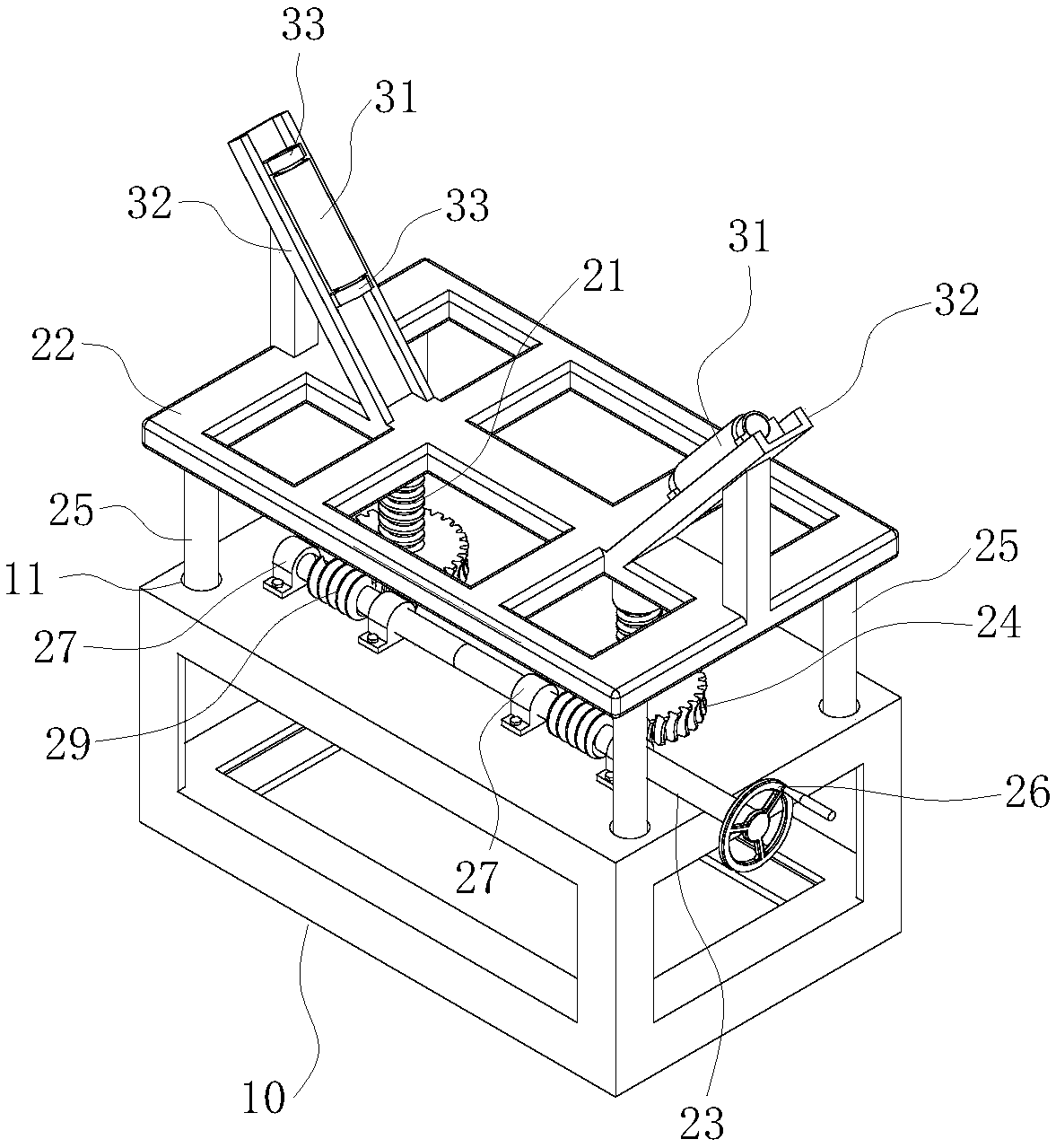

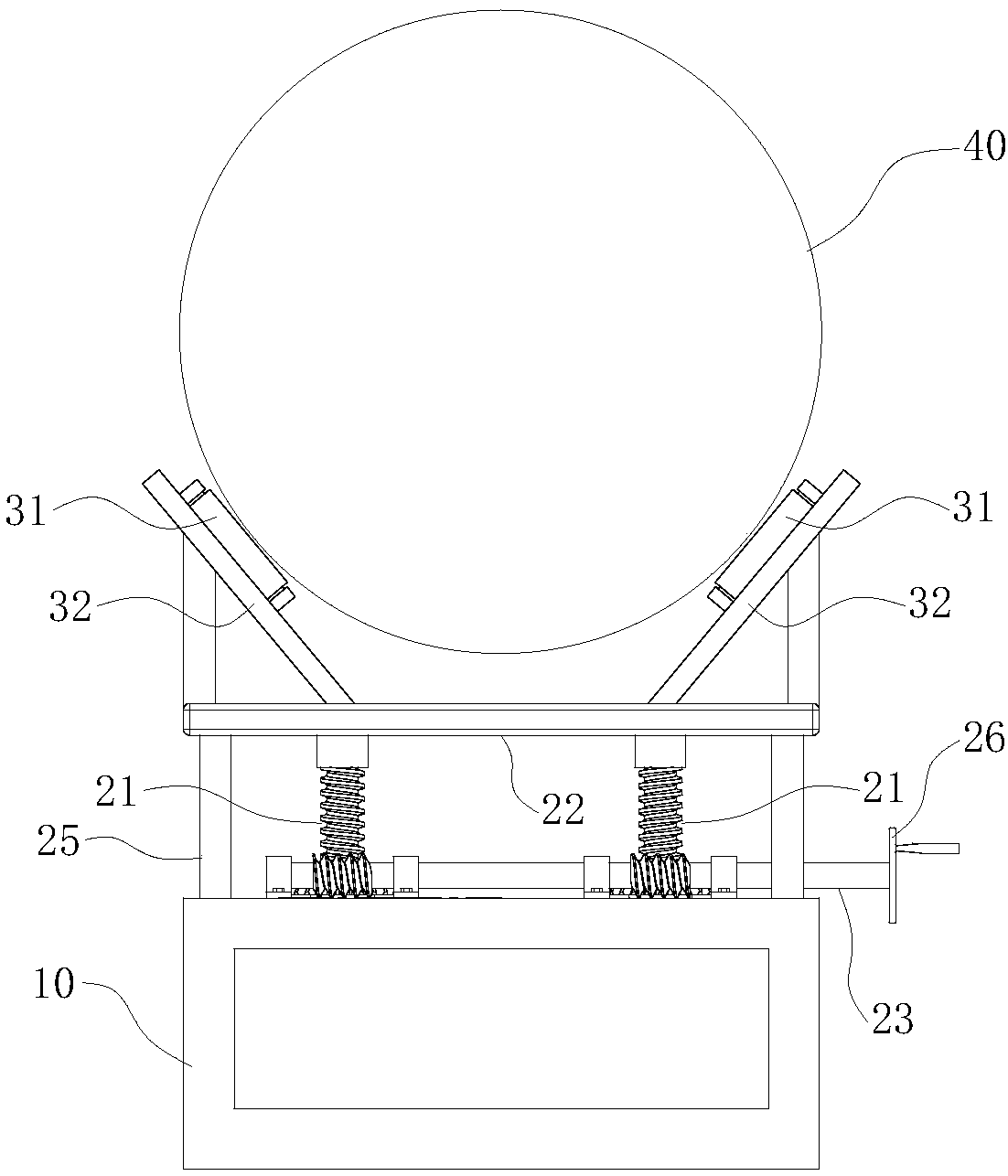

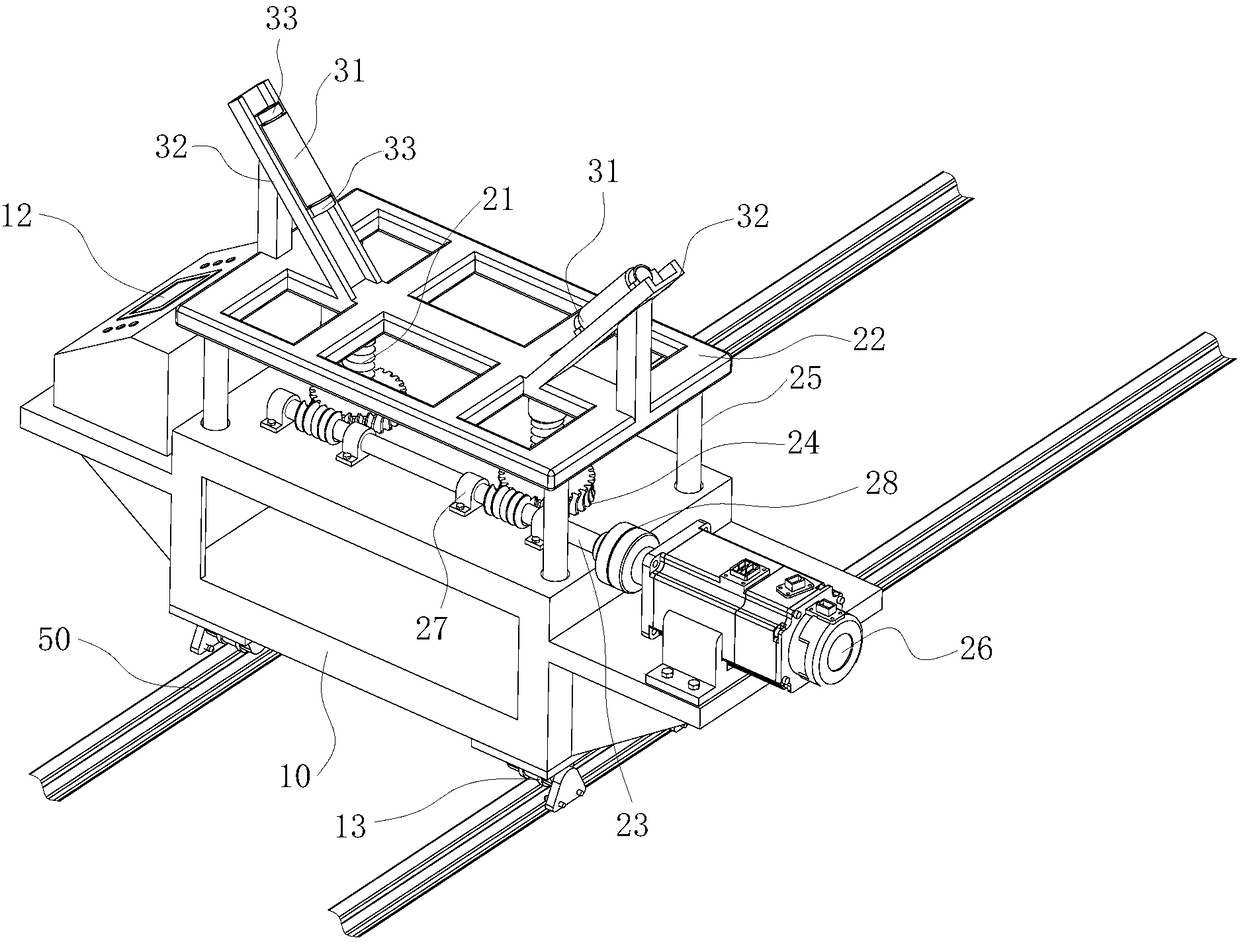

[0029] Now illustrate structural features of the present invention in conjunction with accompanying drawing:

[0030] Such as figure 1 , 2 , 3: the present invention includes a guide rail 50, a base 10 installed on the guide rail 50 and movable along the guide rail 50, and a pipeline lifting mechanism and a pipeline support mechanism located above the base 10;

[0031] The pipeline lifting mechanism includes a lifting stud 21, a worm gear pair and a bracket body 22 installed on the upper end of the lifting stud 21. The worm 23 is horizontally installed on the base 10 through a supporting bearing 27. The worm gear 24 is sleeved on the lifting stud 21 and threadedly matched with the lifting stud 21, and the secondary action of the worm gear drives the lifting stud 21 to move up and down.

[0032] The pipeline support mechanism includes a plurality of cylindrical rollers 31 installed above the bracket body 22 and used to support the pipeline 40 , the cylindrical rollers 31 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com