Shakeproof pipe support frame

A support frame and anti-vibration technology, applied in the direction of pipe supports, pipe elements, pipes/pipe joints/pipe fittings, etc., can solve the problems of inability to adjust according to needs, small adaptability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

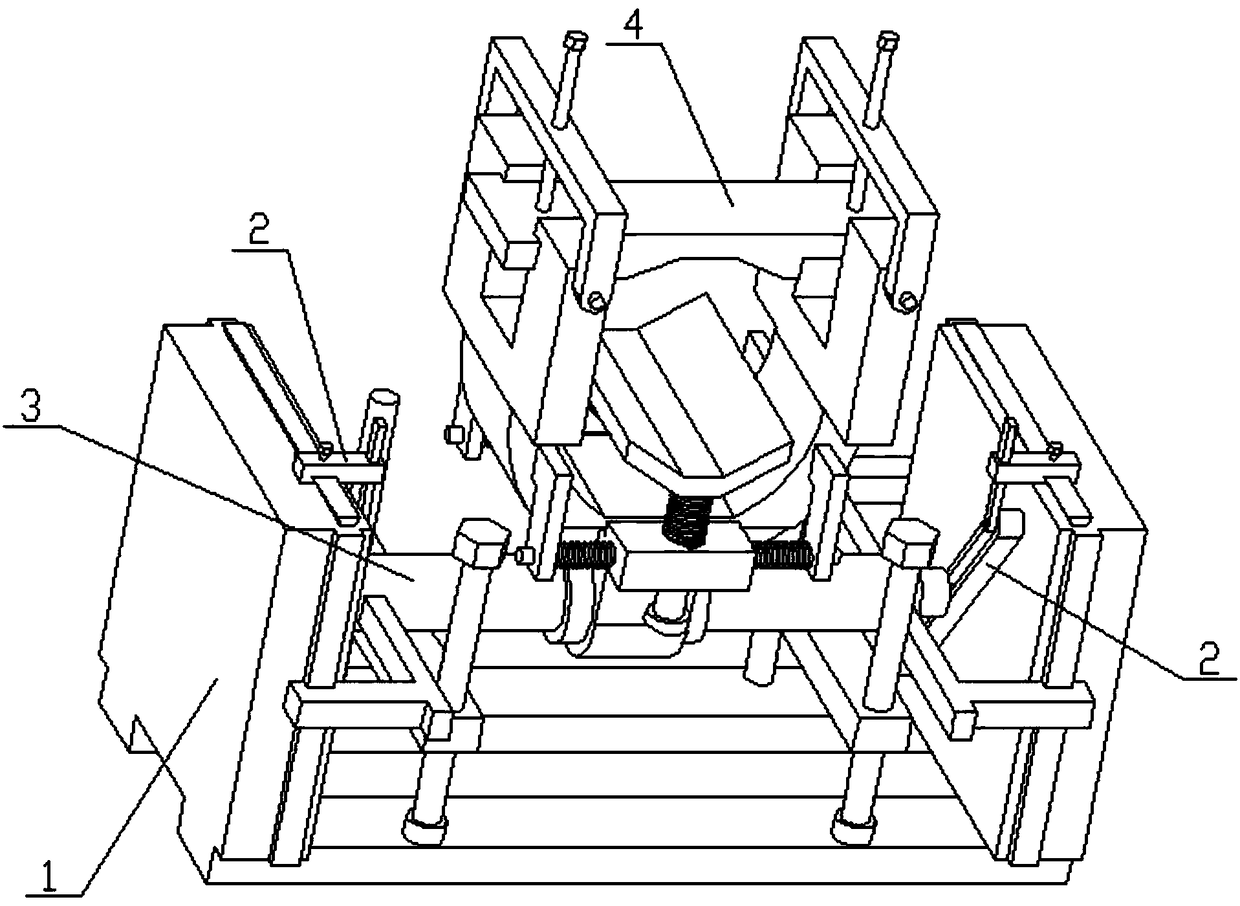

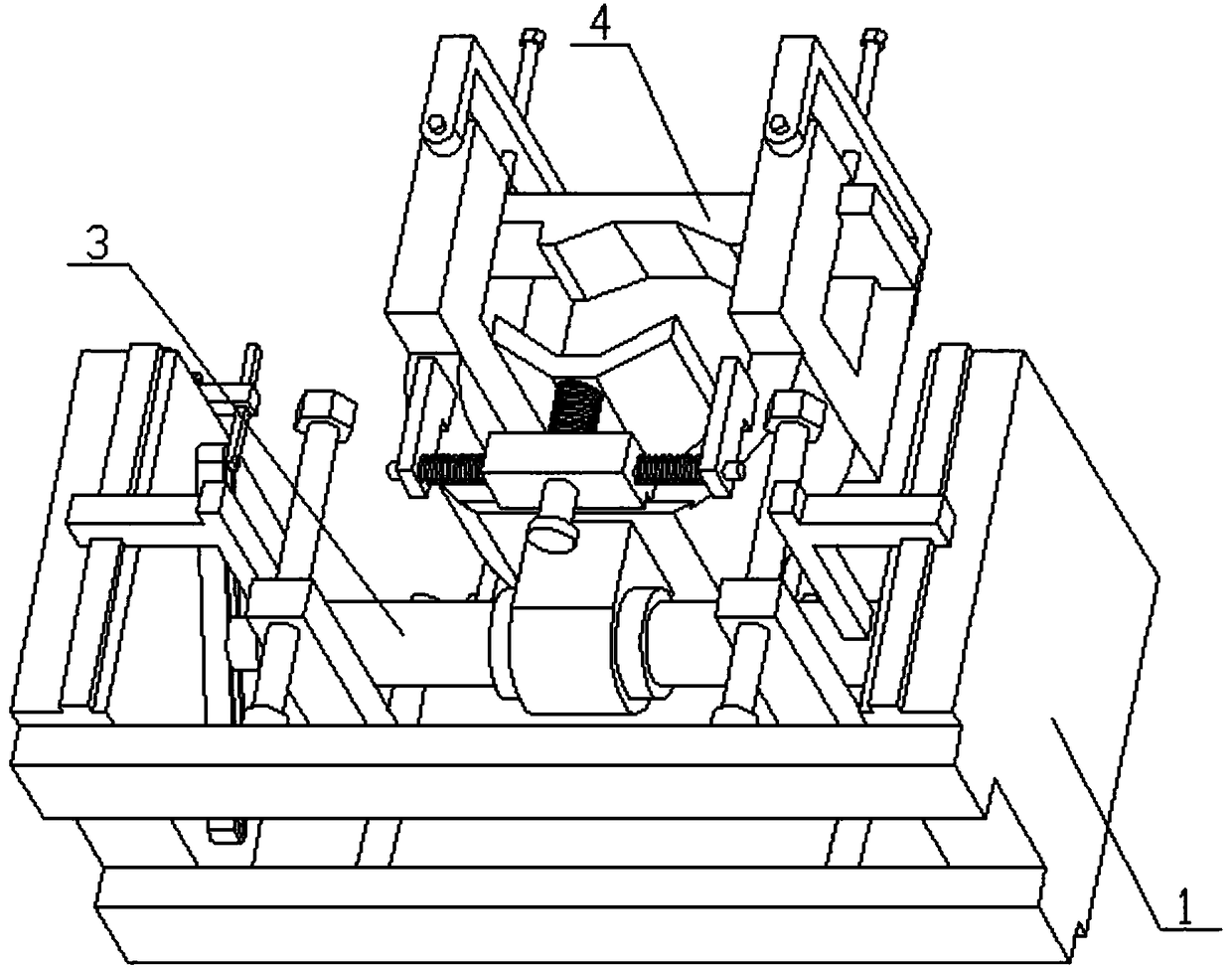

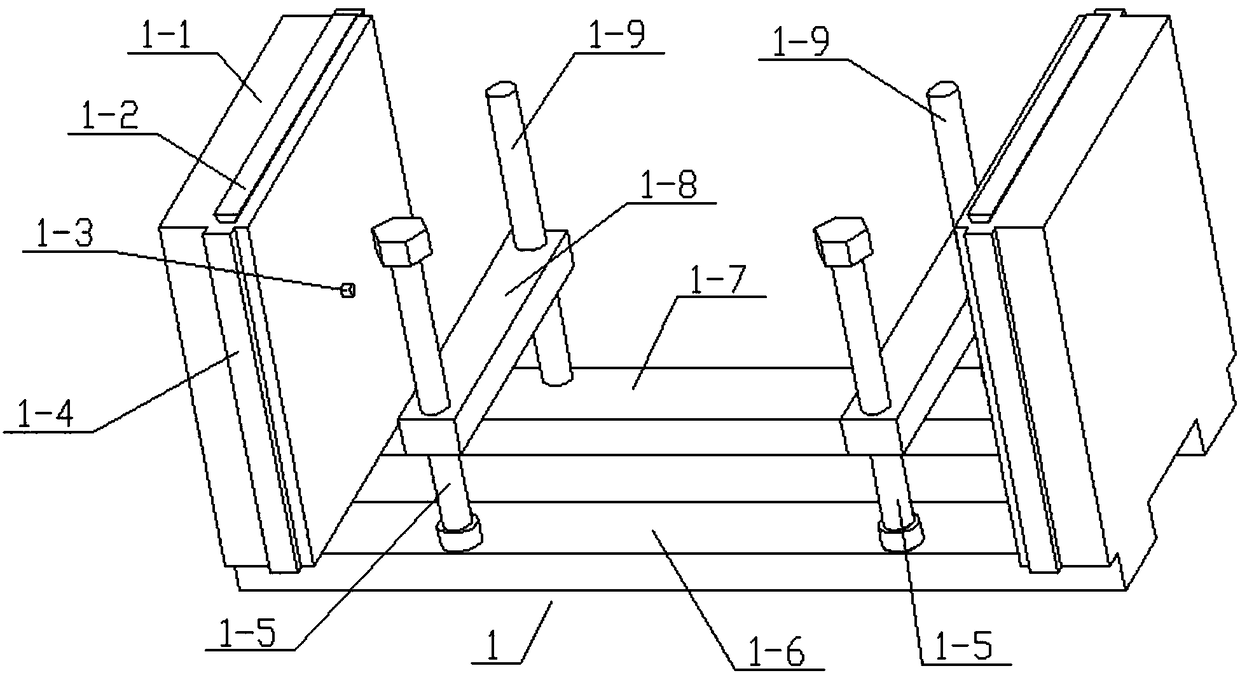

[0029] Combine below Figure 1-14 Describe this embodiment. The present invention relates to the field of pipeline laying engineering, more specifically, an anti-vibration pipeline support frame, including a frame assembly 1, a groove bar assembly 2, a horizontal frame assembly 3 and a pipe frame 4, and the device supports the height of the pipeline. The left and right positions can be adjusted, and the device can adapt to the laying of inclined pipes at a certain angle to the ground, and the device has a shockproof effect.

[0030] The pipe frame 4 includes a U-shaped frame 4-1, a pipe lower support plate assembly 4-2, a pipe vertical baffle 4-3, an upper platen chute 4-4, a door rod 4-5, and a long screw 4- 6, upper pressing plate 4-7, spring baffle plate 4-8, rotating convex seat 4-9 and trapezoidal transverse groove 4-10, the lower end of U-shaped frame 4-1 is fixedly connected with rotating convex seat 4-9, U-shaped frame The front end and rear end of the lower end of 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com