Thrust measurement system for micro thrustor in simulated vacuum environment

A technology of micro-thrust and measurement system, which is applied to force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems of large interference, inconvenient operation and complex system structure of micro-thrust measurement, so as to reduce the number of experiments. Error, good sealing, accurate and objective measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

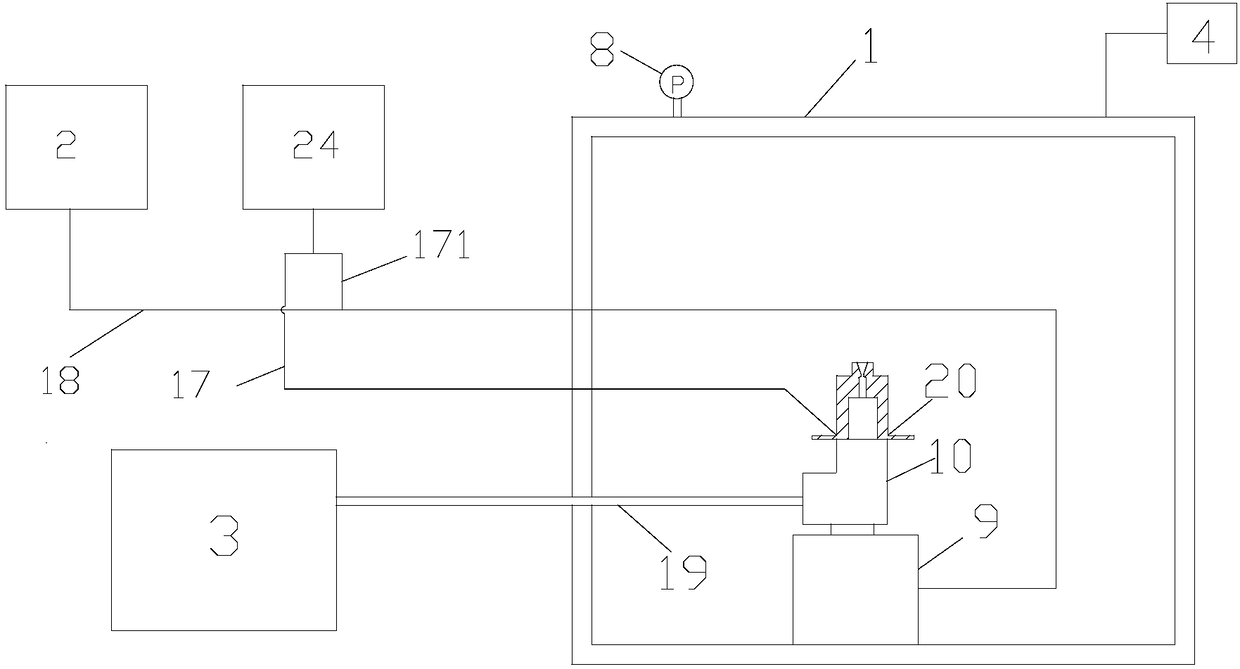

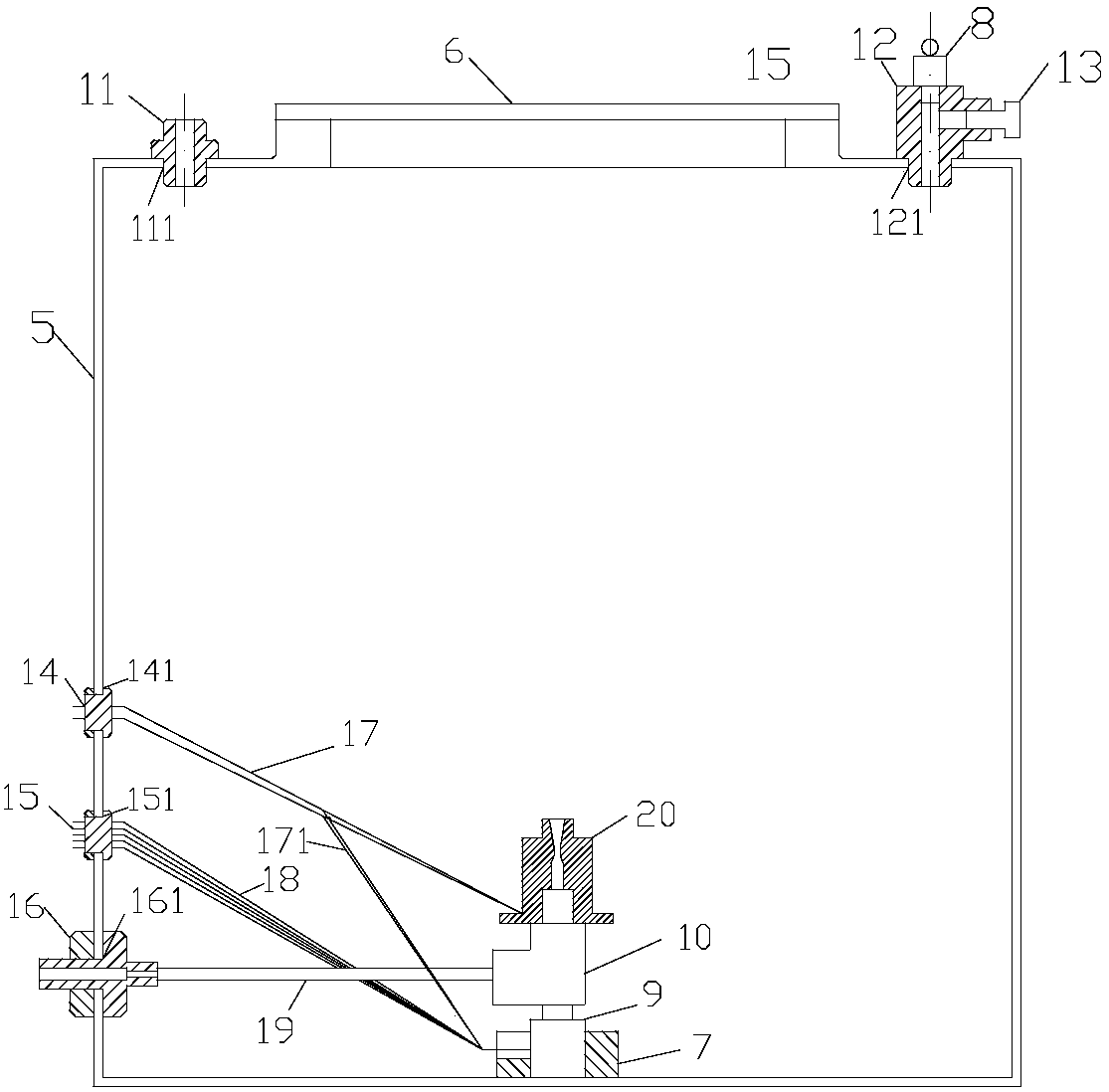

[0018] Below, in conjunction with Figure 1~4 , Further explain the specific implementation of the present invention.

[0019] The invention is a micro-thruster thrust measurement system under simulated vacuum environment, including vacuum thrust measurement device 1, data processor 2, high-pressure gas cylinder 3, vacuum pump 4, vacuum pressure sensor 8, thrust sensor 9, and right-angle adapter 10 , Vacuum pump connector 11, pressure relief valve connector 12, pressure relief valve 13, power cord connector 14, signal line connector 15, hose connector 16, micro thruster power cord 17, sensor power cord 171, signal line 18, hose 19 , Micro thruster 20, power supply 24;

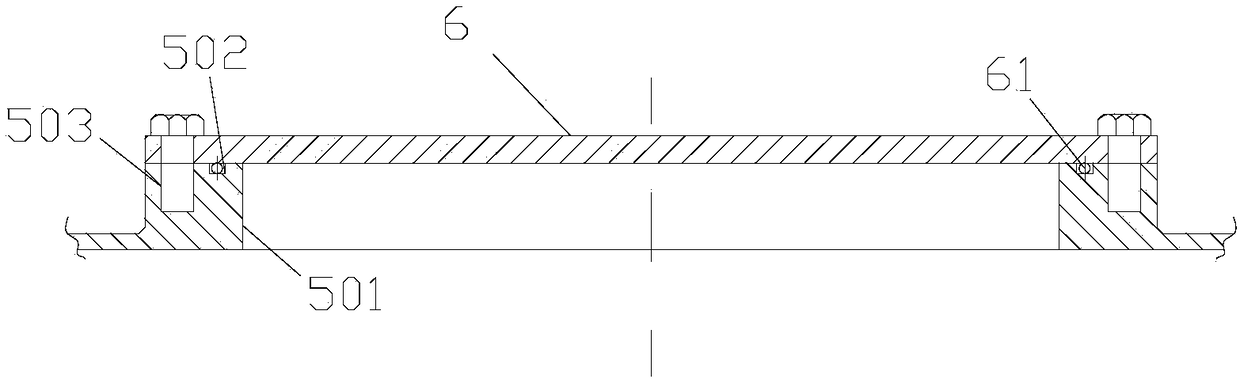

[0020] Wherein, the vacuum thrust measuring device includes a vacuum chamber 5, a sealing cover 6, a base 7 fixed to the bottom of the chamber, and through holes 111, 121, 141, 151, and 161 are respectively reserved on the outer wall of the vacuum chamber. The hole 111 is used to install the vacuum pump connector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com