An industrial waste treatment equipment

A technology for processing equipment and industrial waste, which is applied in the field of pollution control, can solve the problems of low utilization rate, difficult separation and complex structure of industrial waste, and achieve the effect of easy screening and utilization and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

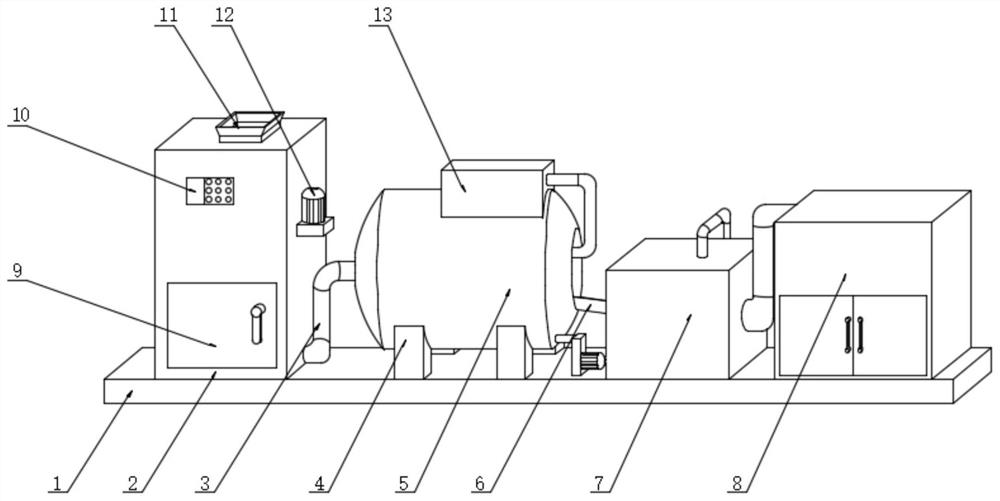

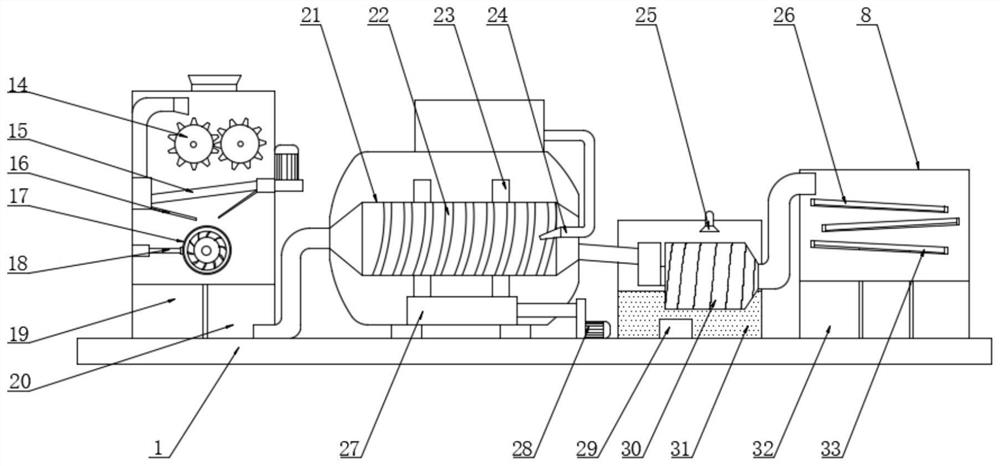

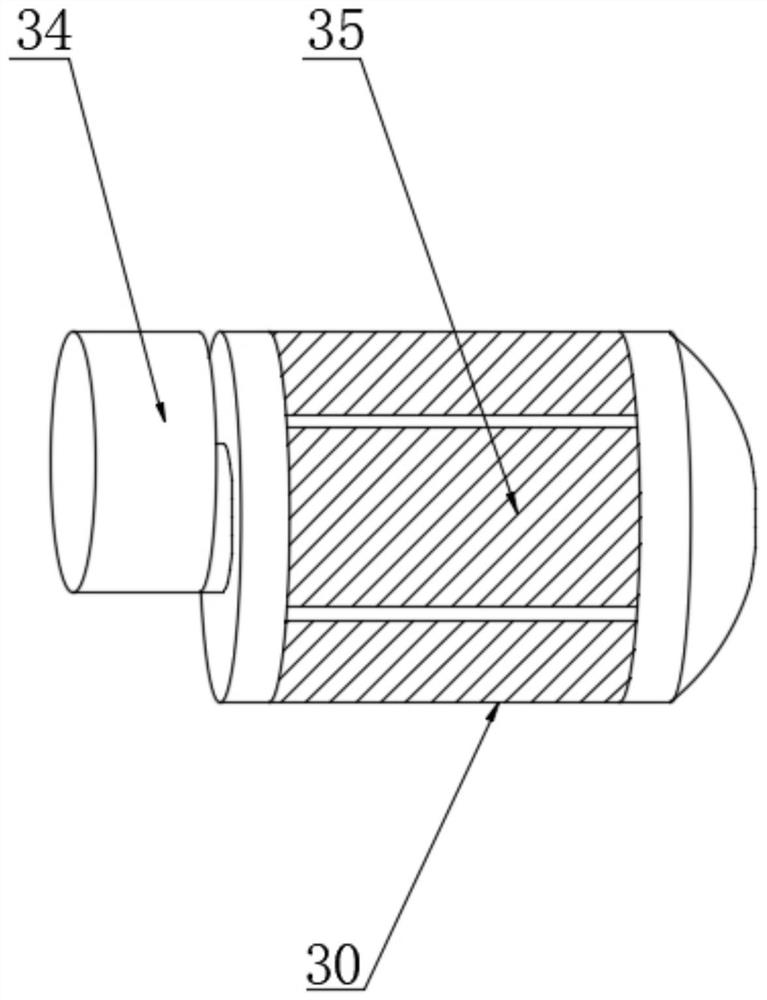

[0030] Example: such as Figure 1-5As shown, the present invention provides a technical solution, an industrial waste slag treatment equipment, including a base 1, a crushing box 2, an auger conveying pipe 3, a support seat 4, a roasting cylinder 5, a conveying pipe 6, a washing box 7, a drying Storage box 8, box door 9, control button 10, feed pipe 11, first motor 12, gas storage tank 13, crushing roller 14, vibrating sieve plate 15, material blocking plate 16, magnetic separation cylinder 17, scraper 18, Iron-containing waste slag storage bin 19, waste bin 20, roasting drum 21, spiral blade 22, transmission rack 23, fire pipe 24, nozzle 25, vibration drying plate 26, transmission box 27, second motor 28, water pump 29 , washing drum 30, cleaning solution 31, grading storage bin 32, grading screening plate 33, feeding pipe 34, washing net 35, electromagnetic plate 36, smooth cylinder sleeve 37 and screen cloth 38, the top side of base 1 is installed with Crushing box 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com