Crushing equipment for processing straw for agricultural planting

A technology for pulverizing equipment and straw, which is applied to the field of pulverizing equipment for processing straw for agricultural planting, can solve the problems of a lot of labor intensity, poor pulverization effect, and poor safety, and achieve the effects of smooth straw pulverization, convenient agricultural planting, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

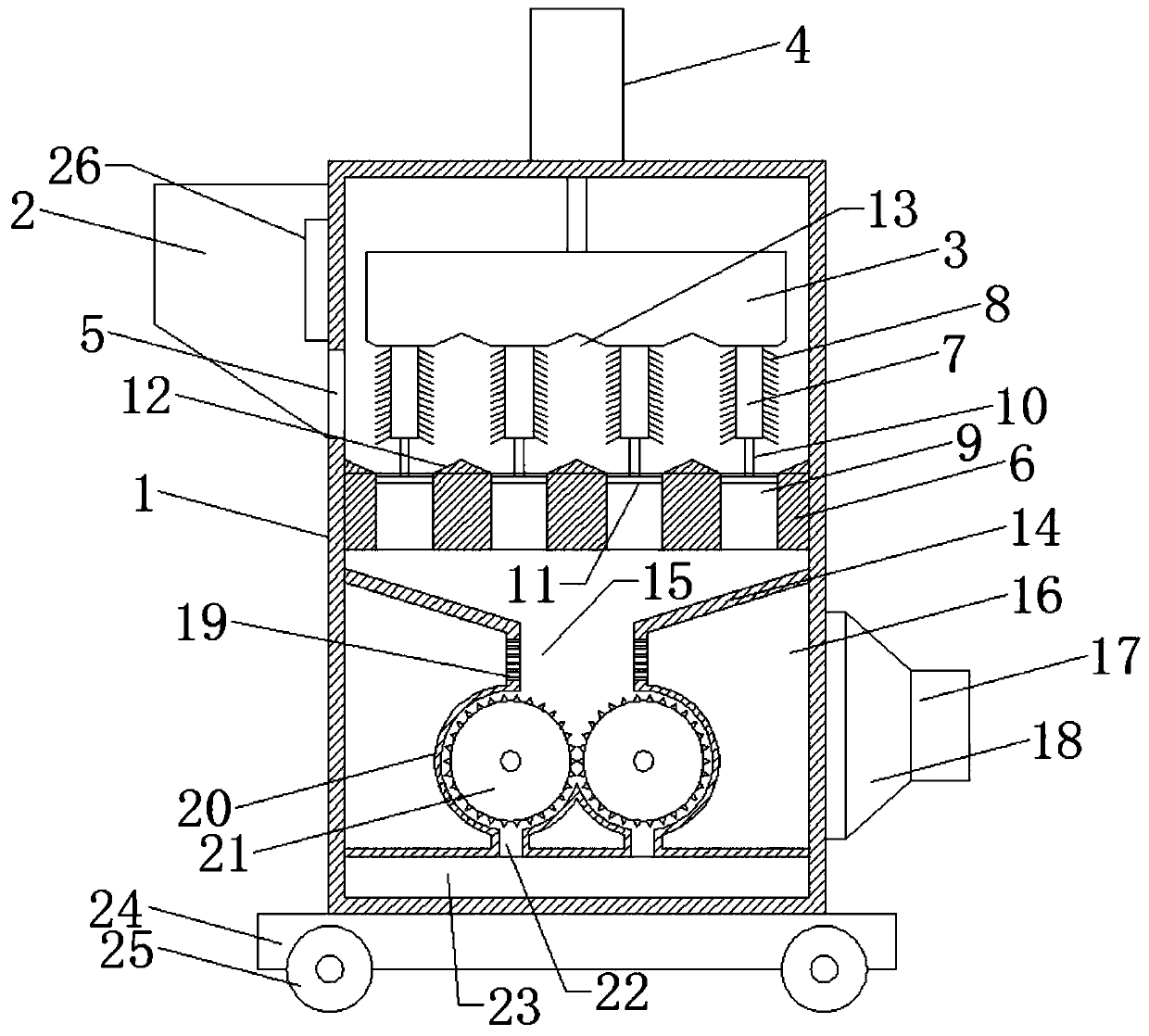

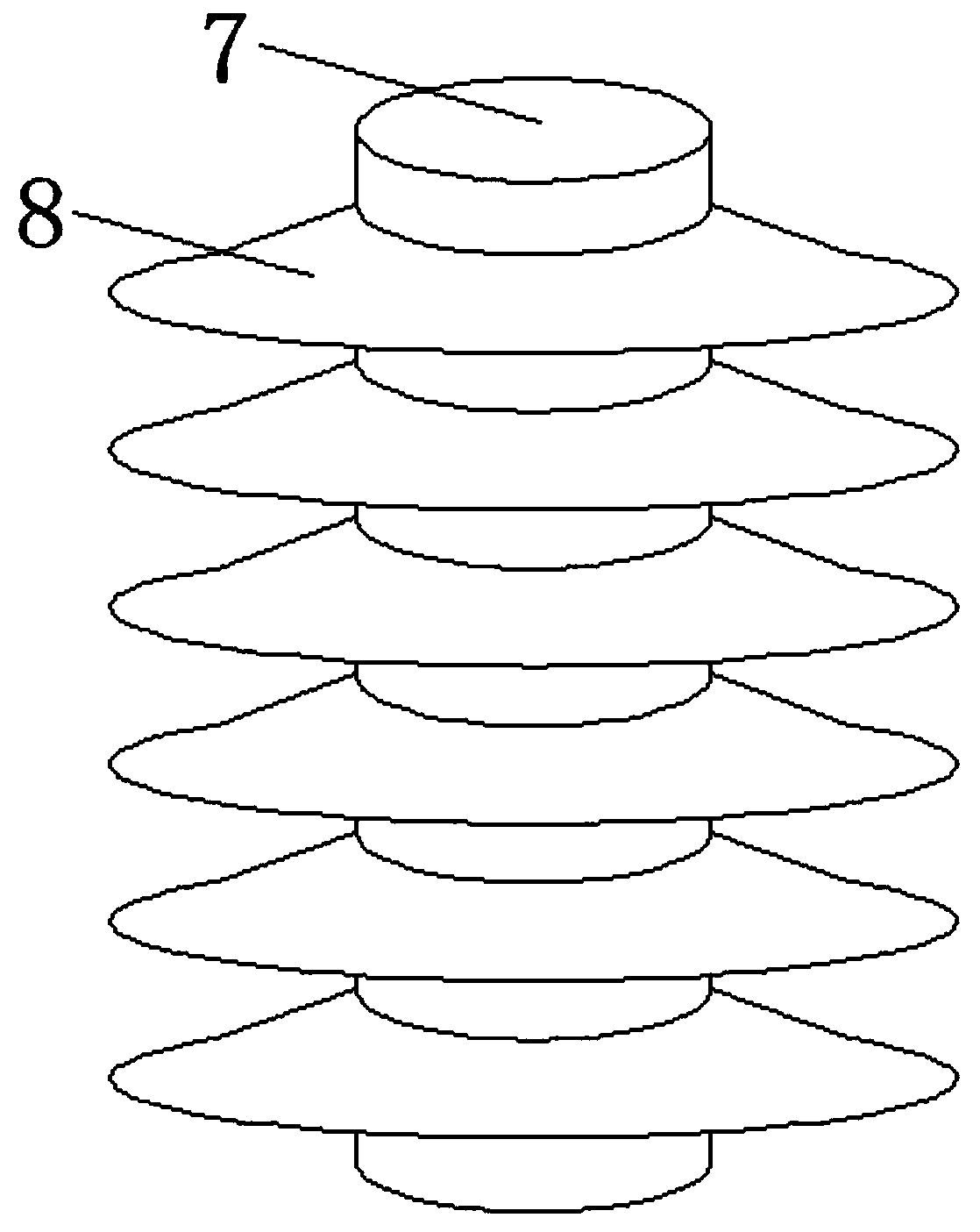

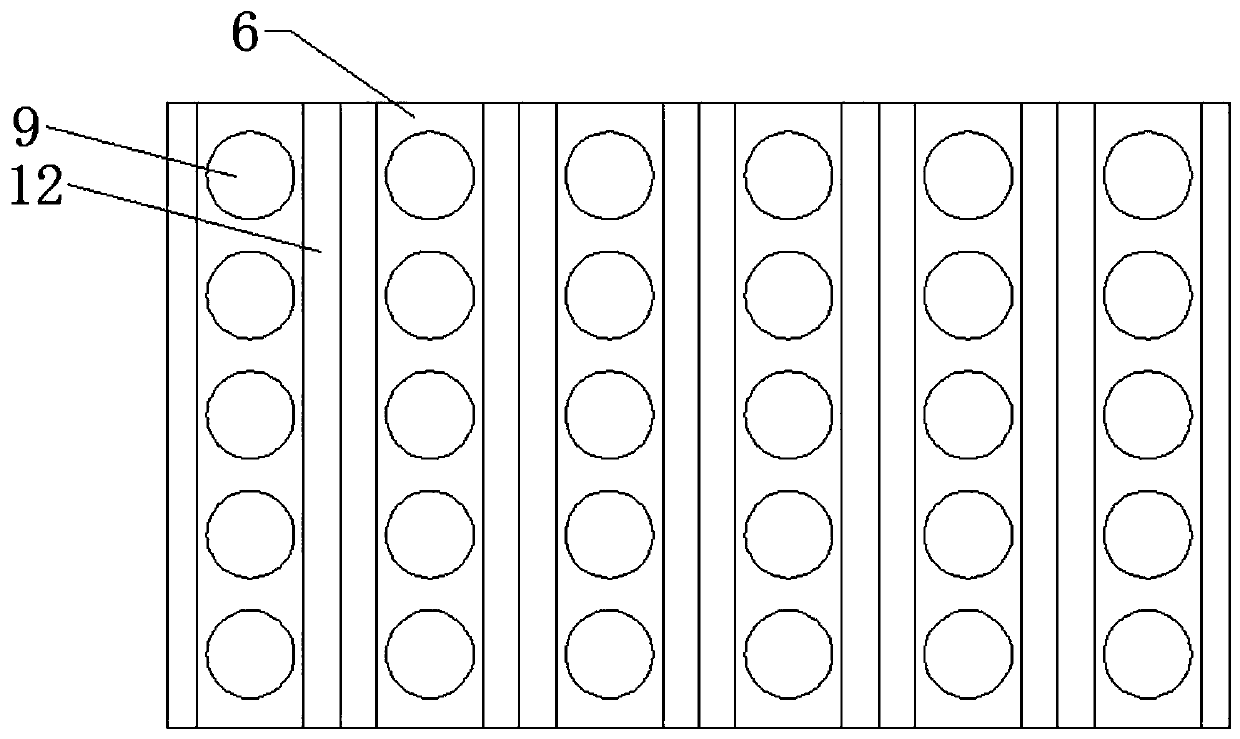

[0018] Please refer to the figure, in the embodiment of the present invention, a kind of crushing equipment for processing straws for agricultural planting includes a housing 1, a feeding hopper 2, a driving device 4, a base 24 and a roller 25; the housing 1 is fixed on the base 24 Above, the rollers 25 are installed on the four corners of the base 24 respectively, so that the equipment can be moved conveniently; A horizontal extruding block 3 is fixed on the output end, and the extruding block 3 is driven to move up and down by the driving device 4. An extruding plate 6 fixed on the inner wall of the housing 1 is arranged under the extruding block 3. The extruding block 3 Move downwards and press on the extrusion plate 6, squeeze and crush the straw falling into it; on the side wall of the housing 1 corresponding above the extrusion plate 6, there is a feed port 5, and the feed port 5 is connected to the The feeding hopper 2 fixed on the outer wall of the housing 1 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com