Servo mark tracking line pressing rotary die cutting machine

A technology of circular pressing and die-cutting machine, applied in the field of servo and standard pressing line circular pressing circular die-cutting machine, which can solve the problems of inaccurate die-cutting positioning, inaccurate forming, inaccurate positioning, etc., and achieve accurate crimping position. , the effect of accurate location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

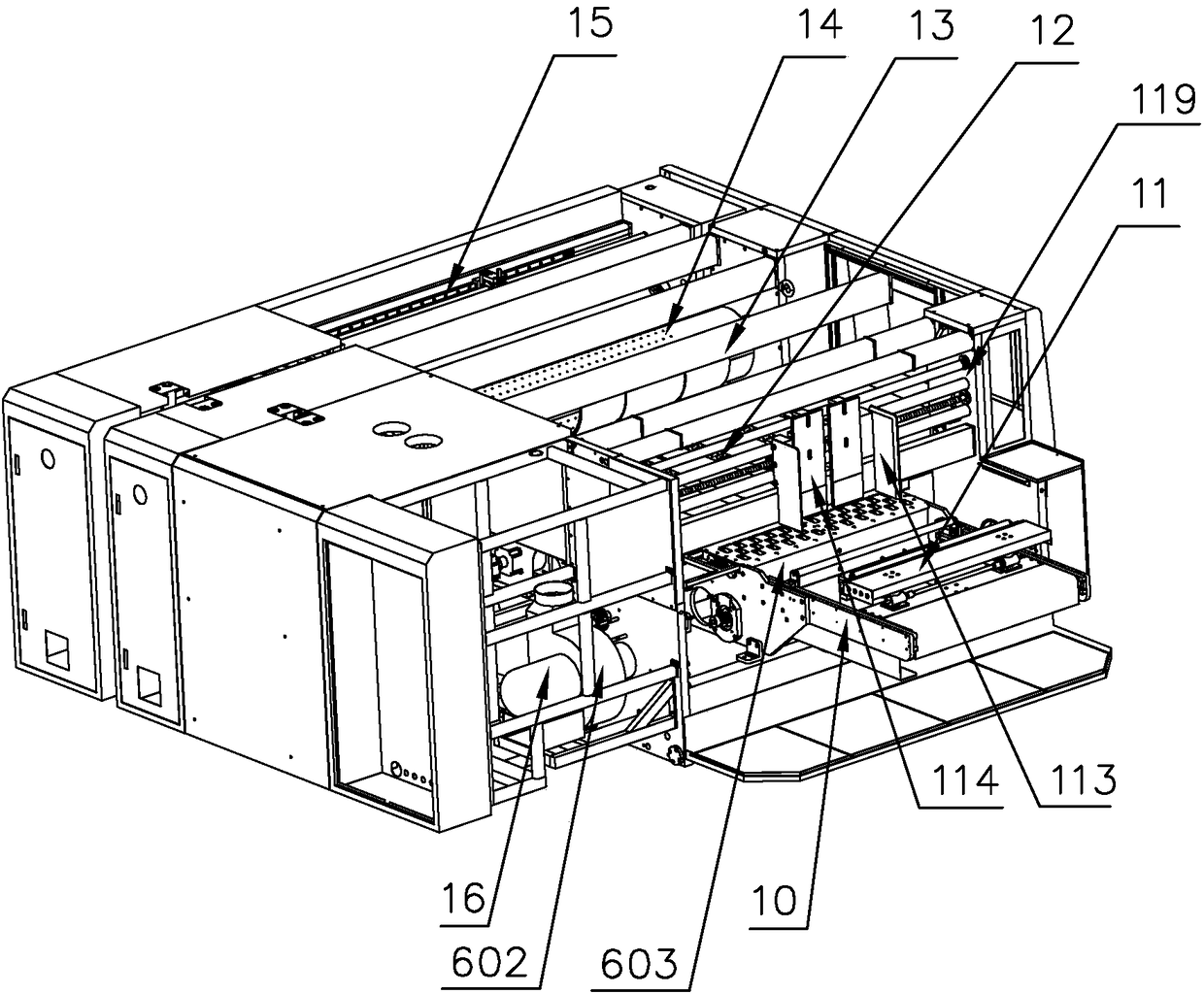

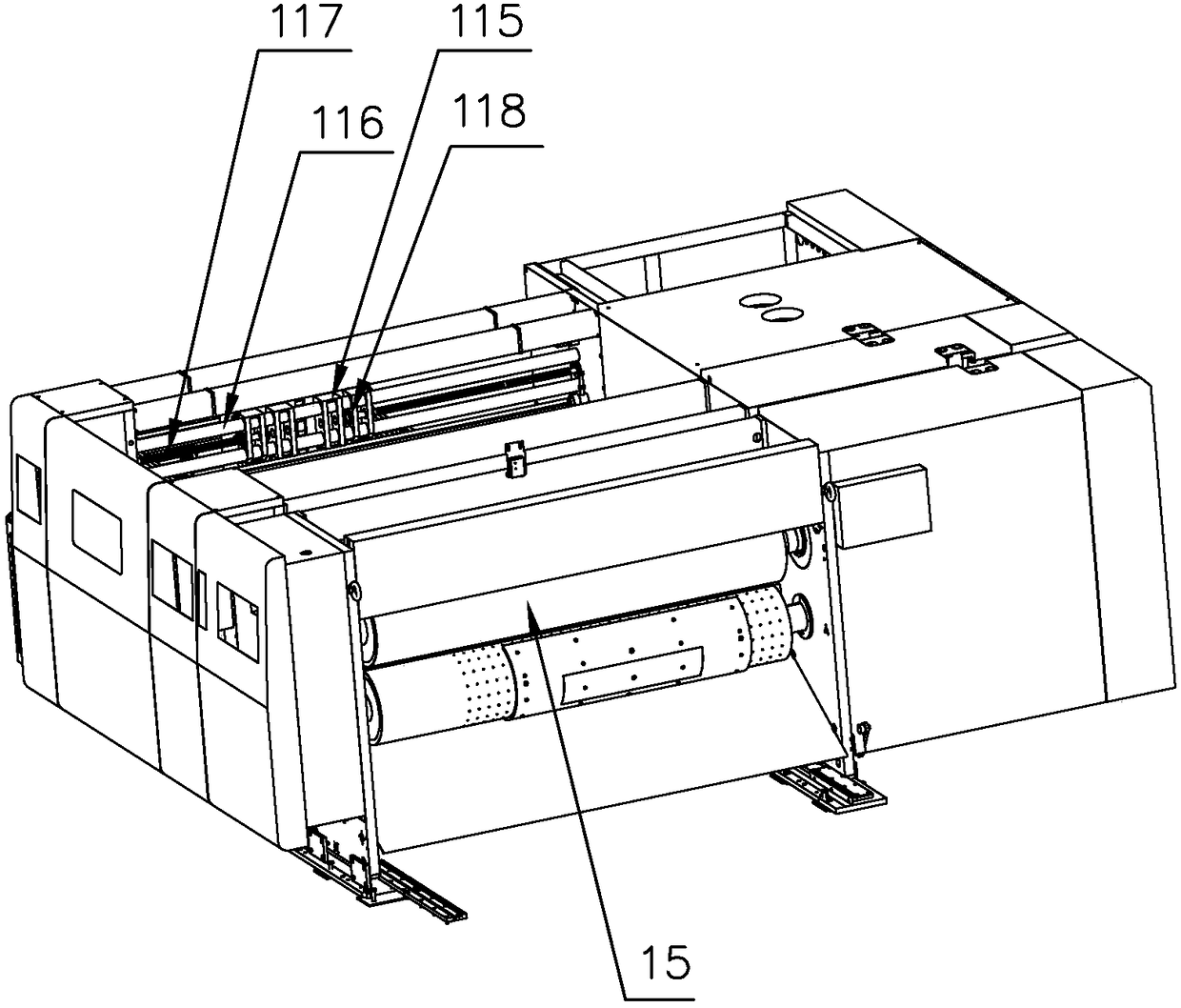

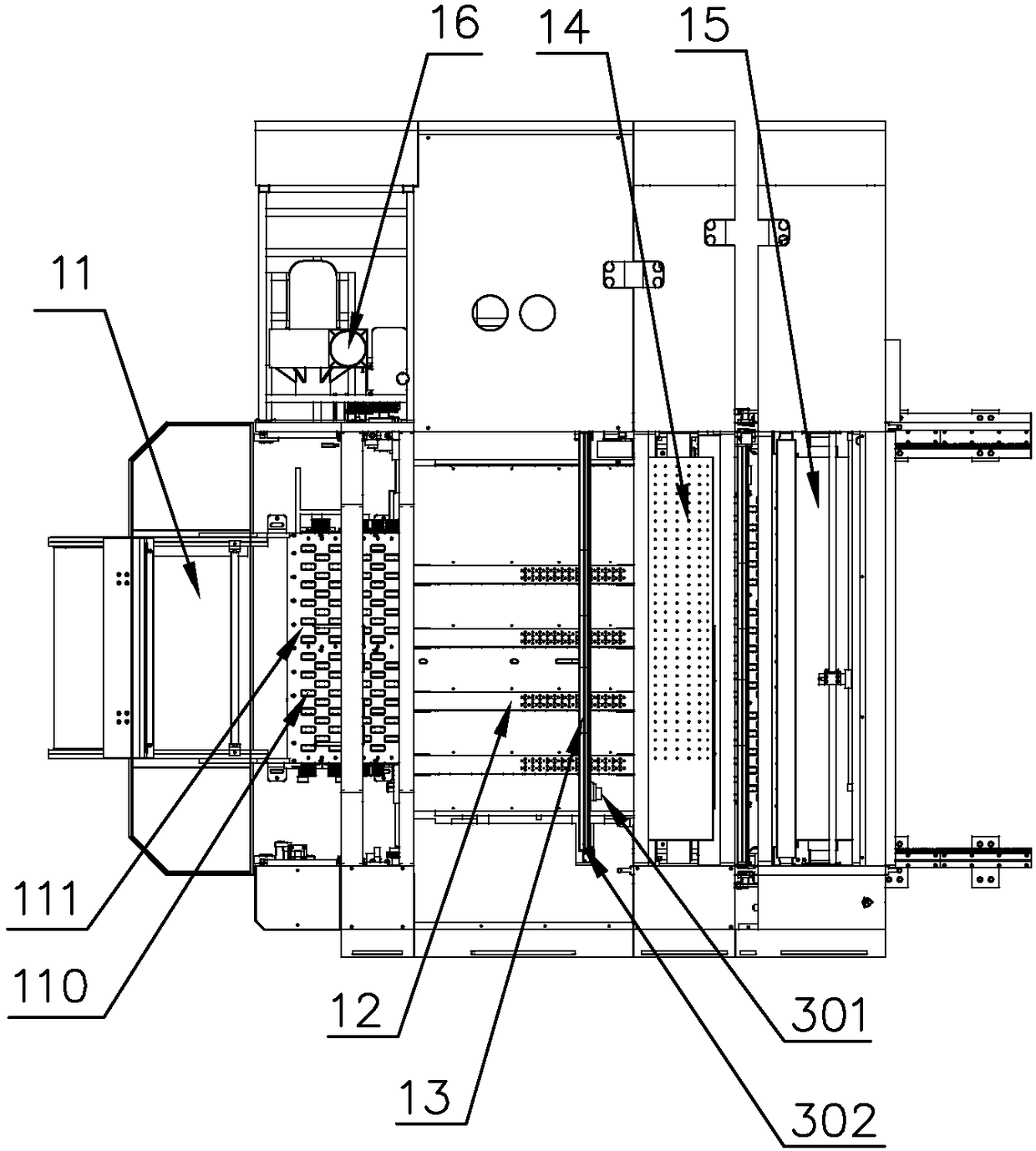

[0039] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-10 , to further specifically describe the technical solution of the present invention.

[0040] A servo follow-up crimping circular die-cutting machine, including a frame 10, a feeding part 11, a conveying mechanism 12 before creasing, a color mark tracking mechanism 13, a creasing mechanism 14, a die-cutting mechanism 15, and a negative pressure adsorption mechanism 16. Horizontal adjustment mechanism 17, the frame 10 is used to carry the feeding part 11, the conveying mechanism 12 before creasing, the color mark tracking mechanism 13, the creasing mechanism 14, the die-cutting mechanism 15, the negative pressure adsorption mechanism 16, and the lateral adjustment mechanism 17 , along the direction of the paper feeding plate, a feeding part 11, a conveying mechanism 12 before creasing, a creasing mechanism 14, and a die-cutting mechanism 15 are arrang...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap