Heated electrolytic sewage treatment pool and sewage treatment method

A sewage treatment method and sewage treatment tank technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problems of low degree of automation, waste of energy, and easy occurrence of large amounts of sedimentation, etc. Problems, to achieve the effect of breaking glue and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

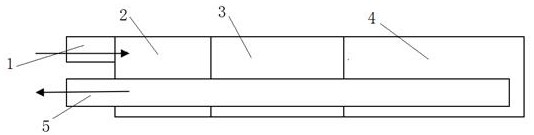

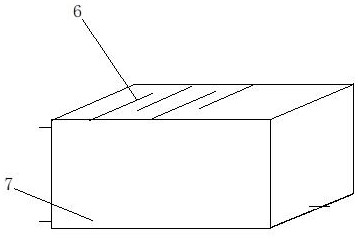

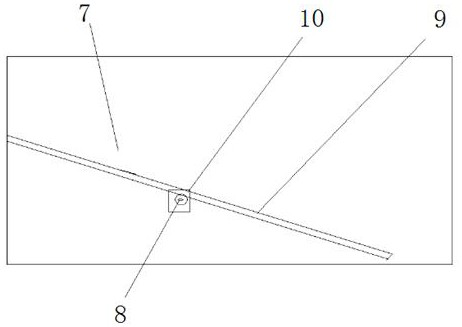

[0026] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0027] Option One:

[0028] The heated electrolytic sewage treatment pool is characterized in that it includes a pool body and an exhaust gas discharge structure leading to the inside of the pool body, and the exhaust gas discharge structure can heat and / or chemically break the sewage in the pool body, The heating gel breaking refers to the use of exhaust gas heating and / or engine heat dissipation to break the sewage gel in the pool body. The chemical gel breaking refers to the combination of the chemical components in the exhaust gas and the substances in the sewage to break the gel. The electrolytic structure in which electrolysis is performed. The substantive technical effect and the realization process of the technical solution here are as follows: use the tail gas discharge structure to heat and / or c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com