Method for reducing shutdown knock of lowering charge level of blast furnace

A technology for lowering material surface and blast furnace, applied in blast furnace, blast furnace details, furnace, etc., can solve the problems of furnace wall refractory falling off, formation of explosive gas, damage to furnace cooling equipment, etc., to meet the needs of environmental protection and reduce knocking Risk, the effect of prolonging payback time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

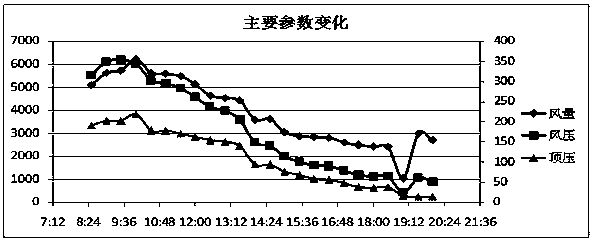

[0031] Example 1: Take Handan Iron and Steel 3200m 3 Taking the shutdown of the blast furnace on the falling material surface on February 27, 2017 as an example, the specific process of the method for reducing the knocking at the falling material surface of the blast furnace is as follows.

[0032] (1) Before the start of the lowering surface, check the three-stage static pressure nitrogen purge pipeline of the furnace body, open the nitrogen valve, and purge the nitrogen flow rate from the normal flow rate of 250m 3 / h increased to 500m 3 / h.

[0033] (2) After the lowering surface starts, increase the nitrogen flow rate of the top airtight box from 1500m 3 / h increased to 3000m 3 / h.

[0034] (3) After pumping water from the top of the furnace starts, the nitrogen flow rate of the valve box on the top of the furnace is changed from the normal flow rate of 600m 3 / h increased to 1200m 3 / h.

[0035] (4) From the lowering surface to the middle of the furnace body, open ...

Embodiment 2

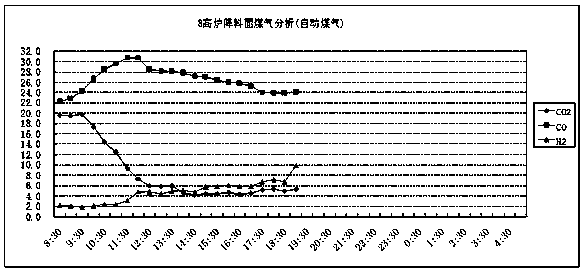

[0040] Embodiment 2: Take Handan Iron and Steel 2000m 3 Taking the shutdown of the blast furnace on the falling material surface on November 6, 2017 as an example, the specific process of the method for reducing the knocking at the falling material surface of the blast furnace is as follows.

[0041] (1) Before the start of the lowering surface, check the three-stage static pressure nitrogen purge pipeline of the furnace body, open the nitrogen valve, and the flow rate of nitrogen purge is changed from the normal flow rate of 200m 3 / h increased to 400m 3 / h.

[0042] (2) After the lowering surface starts, increase the nitrogen flow rate of the airtight box on the top of the furnace, from 1300m 3 / h gradually increased to 3250m 3 / h.

[0043] (3) After pumping water from the top of the furnace starts, the nitrogen flow rate of the valve box on the top of the furnace is changed from the normal flow rate of 500m 3 / h increased to 900m 3 / h.

[0044] (4) From the lowering ...

Embodiment 3

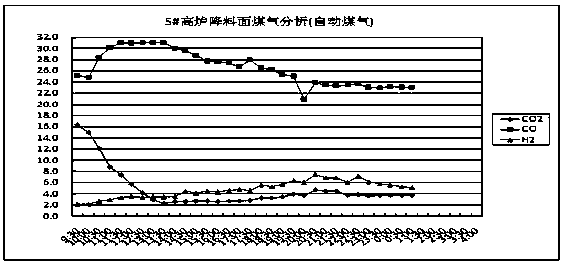

[0049] Embodiment 3: Take Handan Iron and Steel 3200m 3 Taking the shutdown of the blast furnace at the lowering surface as an example, the specific process of the method for reducing knocking at the lowering surface of the blast furnace is as follows.

[0050] (1) Before the start of the lowering surface, check the three-stage static pressure nitrogen purge pipeline of the furnace body, open the nitrogen valve, and the flow rate of nitrogen purge is changed from the normal flow rate of 200m 3 / h increased to 400m 3 / h.

[0051] (2) After the lowering surface starts, increase the nitrogen flow rate of the airtight box on the top of the furnace, from 1400m 3 / h increased to 3080m 3 / h.

[0052] (3) After pumping water from the top of the furnace, the nitrogen flow rate of the valve box on the top of the furnace is changed from the normal flow rate of 800m 3 / h increased to 1200m 3 / h.

[0053] (4) From the lowering surface to the middle of the furnace body, open a materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com