Combination building method for brick masonry comprising sliding layer

A technology of brick masonry and sliding layer, which is applied in the direction of building components, walls, buildings, etc., can solve problems such as lack, external wall cracking, wall leakage, etc., to offset accumulated deformation, prevent masonry cracking, and eliminate masonry cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

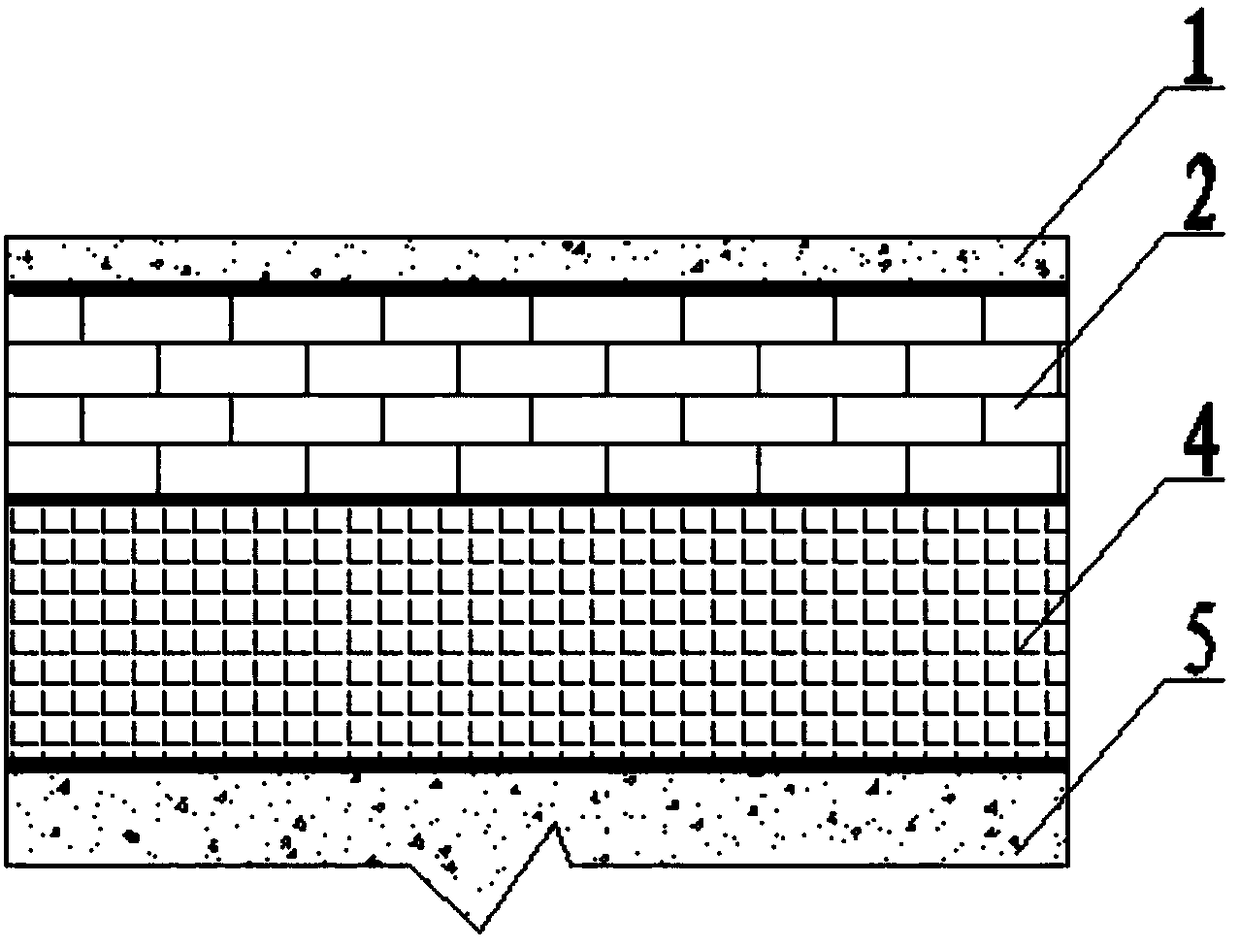

[0029] A method for building brickwork comprising a sliding layer, comprising the steps of:

[0030] (1) First build concrete 5, and the flatness of the upper surface of the concrete must meet the requirements;

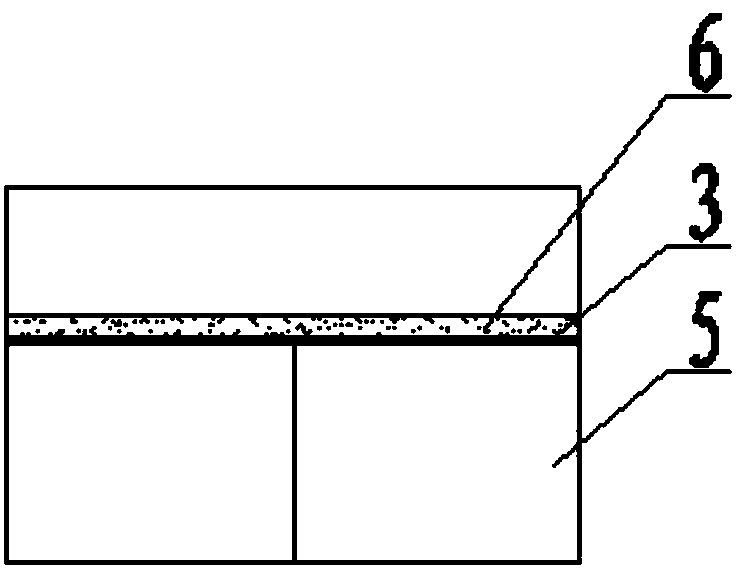

[0031] (2) Lay special linoleum 3, mortar 6 and masonry 4 on the upper surface of the concrete in sequence, and continue laying masonry. After the lower masonry is laid, lay special linoleum and mortar again and change masonry 2 (structure or material) to continue laying,

[0032] (3) Lay mortar on the special linoleum. When the upper part of the special linoleum is cast-in-situ concrete 1, no more mortar should be laid;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com