Rotating machinery bearing fault diagnosis method

A technology for fault diagnosis and rotating machinery, which is used in mechanical bearing testing, mechanical component testing, machine/structural component testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Below in conjunction with accompanying drawing of description, the present invention will be further described.

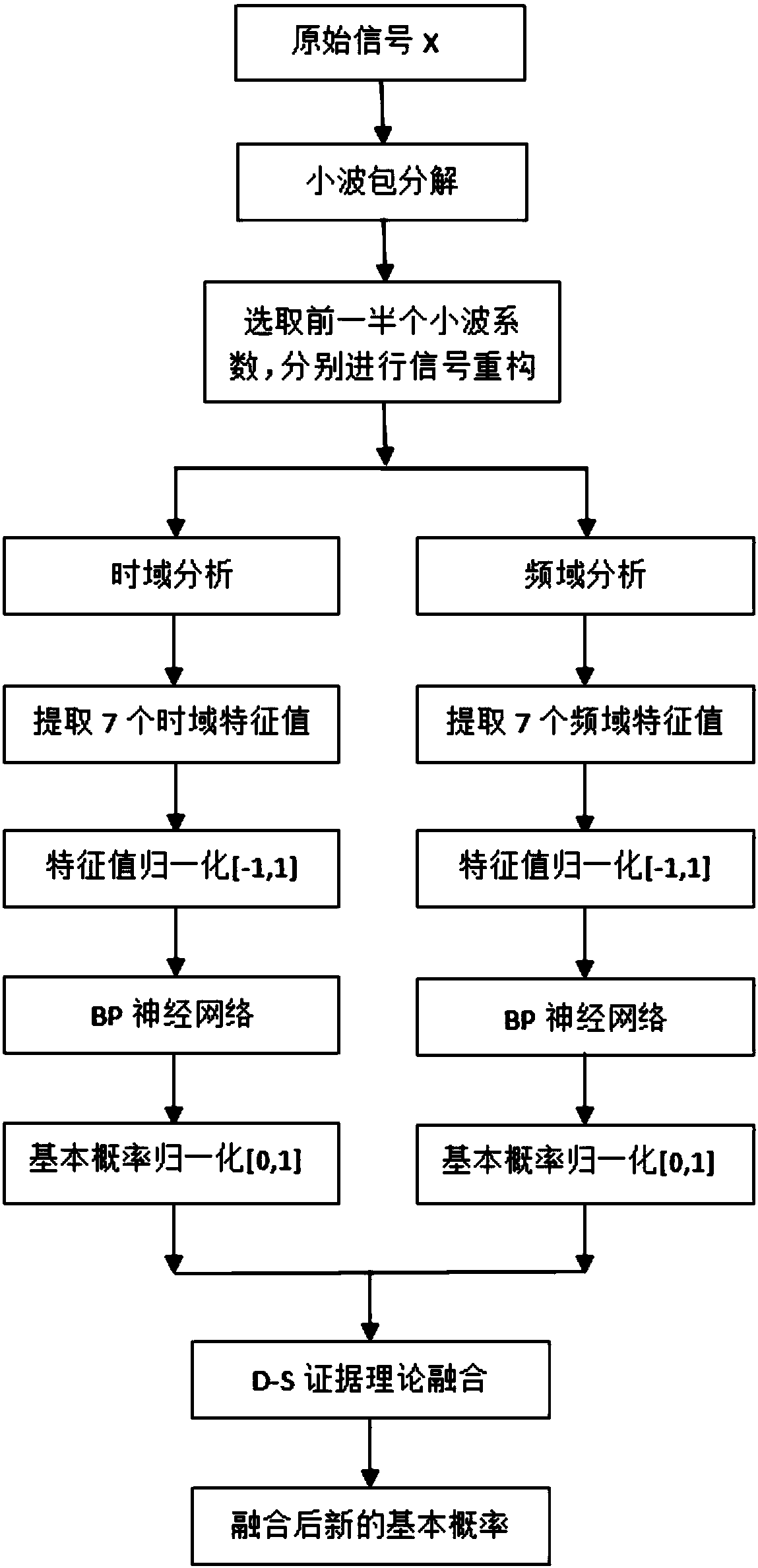

[0075] The invention provides a method for fault diagnosis of rotating machinery bearings, such as figure 1 shown, including the following steps:

[0076] 1) Obtain the vibration signal of the mechanical bearing through the vibration sensor installed on the gearbox of the rotating equipment X i , and the vibration signal X i The collection is summarized as the original signal X=[X 1 ,X 2 ,...,X i ], where 1≤i≤N, N is the number of data points.

[0077] The vibration sensor is preferably installed on the gearbox case close to the oil inlet of the gearbox. The original signal includes the vibration signal of the normal state of the bearing, the vibration signal of the wear of the inner ring of the bearing, the vibration signal of the wear of the outer ring of the bearing and the vibration signal of the bearing ball. Vibration sign of wear and tear.

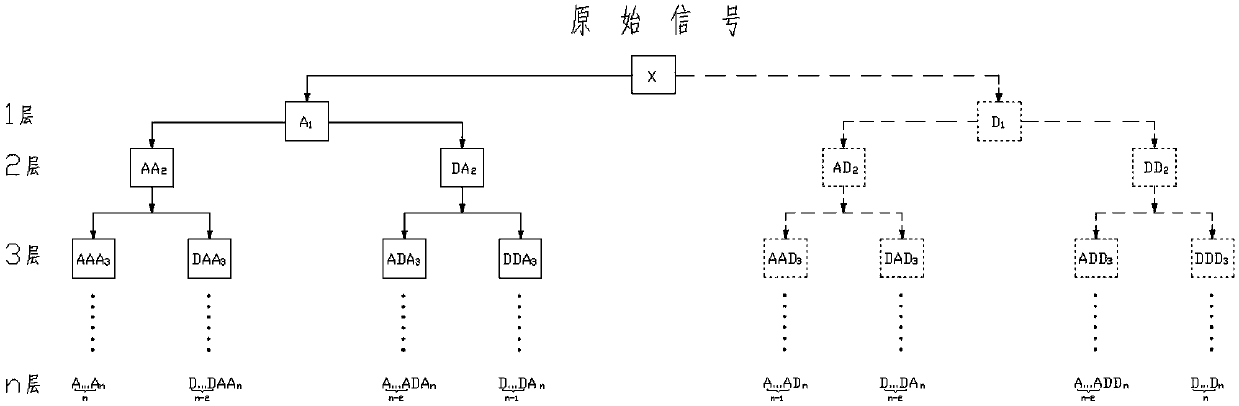

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com