Optical tweezers control method based on hollow light dimension adjustment and optical tweezers control device based on hollow light dimension adjustment

A technology of size adjustment and manipulation device, applied in the field of nonlinear optics, can solve the problems of high price, damage to the physical machine, inability to achieve precise control, etc., and achieve the effect of simple structure, easy operation, and avoidance of light damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] According to the above-mentioned technical scheme, the present invention discloses a method for manipulating optical tweezers based on hollow optical size adjustment, which includes the following steps:

[0034] Step 1, obtaining a modulated laser beam 1 and focusing it in a nonlinear medium 6;

[0035] Step 2, obtaining another beam of modulated laser beam 2 and incident it in the nonlinear medium 6 in step 1, and then entering the optical tweezers system after passing through the first polarization beam splitting cube 5;

[0036] Specifically, the modulated laser beam 2 is incident on the nonlinear medium 6 described in step 1, so that it propagates anti-collinearly with the modulated laser beam 1 described in step 1, and the modulated laser beam 2 travels from the nonlinear medium 6 enters the optical tweezers system through the first polarization beam splitting cube 5 after exiting.

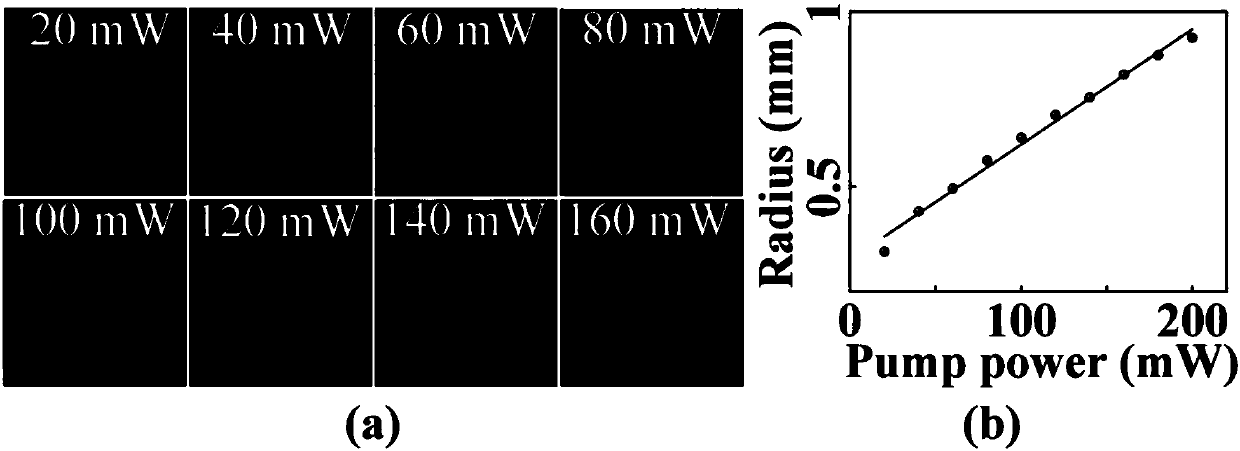

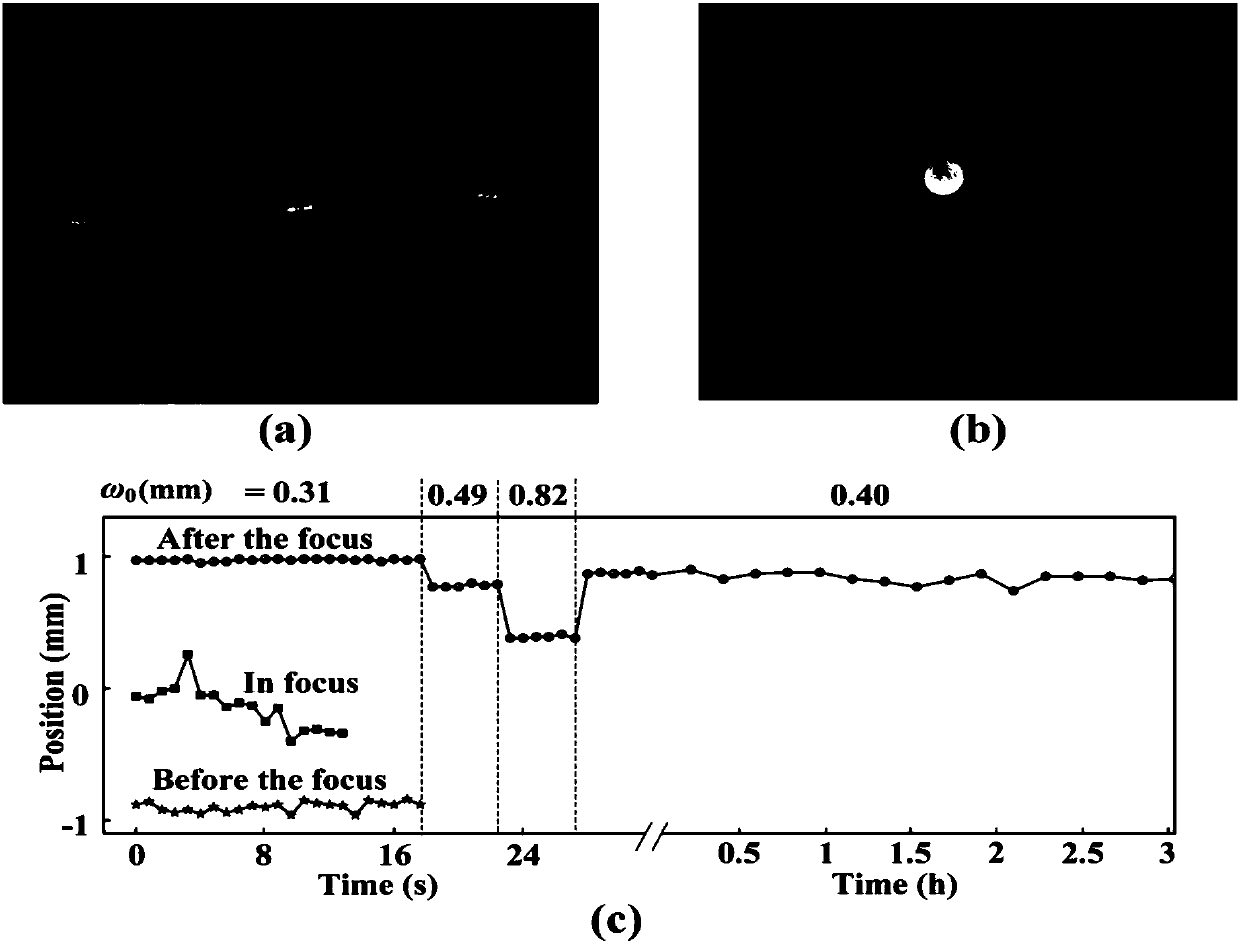

[0037] Step 3, adjusting the light intensity of the modulated laser beam 1 and th...

Embodiment 2

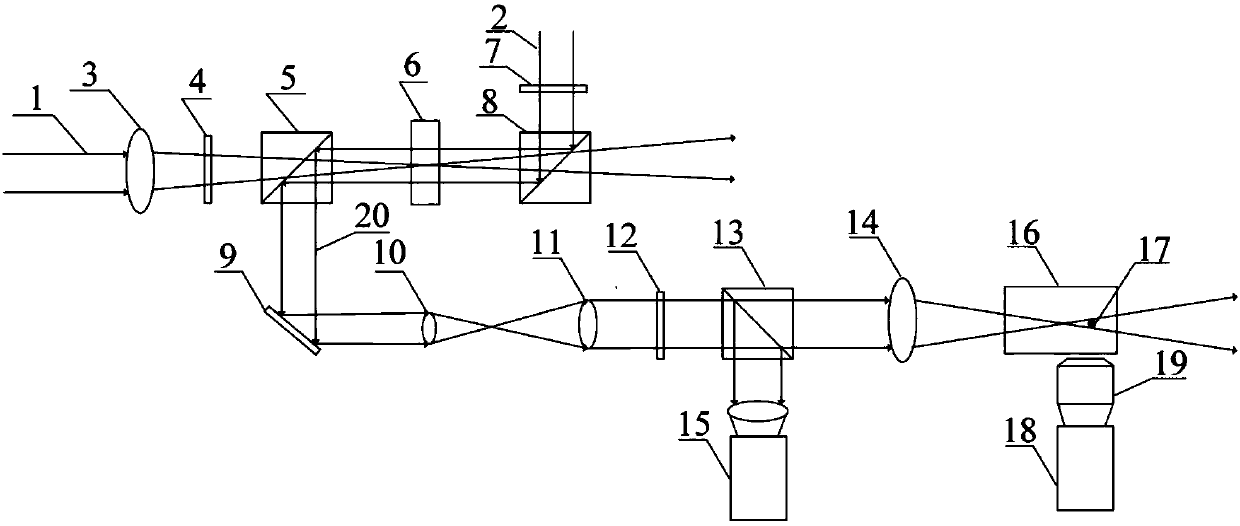

[0049] like figure 1 As shown, the present embodiment provides an optical tweezers manipulation device based on hollow light size adjustment, including a focusing lens 3, a first half-wave plate 4, a second half-wave plate 7, a first polarization splitting cube 5, a second polarization The beam-splitting cube 8, the nonlinear medium 6 and the optical tweezers system, the focusing lens 3, the first half-wave plate 4, the first polarization beam-splitting cube 5, the nonlinear medium 6 and the second polarization beam-splitting cube 8 are sequentially arranged on the horizontal plane of the same optical path propagation , the second half-wave plate 2 is located directly above the second polarization beam-splitting cube 8 , and the optical tweezers system is located below the first polarization beam-splitting cube 5 .

[0050] The optical tweezers system in the present embodiment comprises a high reflection mirror 9, a second focusing lens 10, a third focusing lens 11, a third ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com