Graded broken stone base plastic deformation prediction model and prediction method

A graded crushed stone and plastic deformation technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems affecting the application of graded crushed stone base, large rutting deformation, and large plastic deformation of graded crushed stone base and other issues, to achieve high reliability, convenience and accurate prediction, and easy calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Establishment of plastic deformation prediction model for graded crushed stone base;

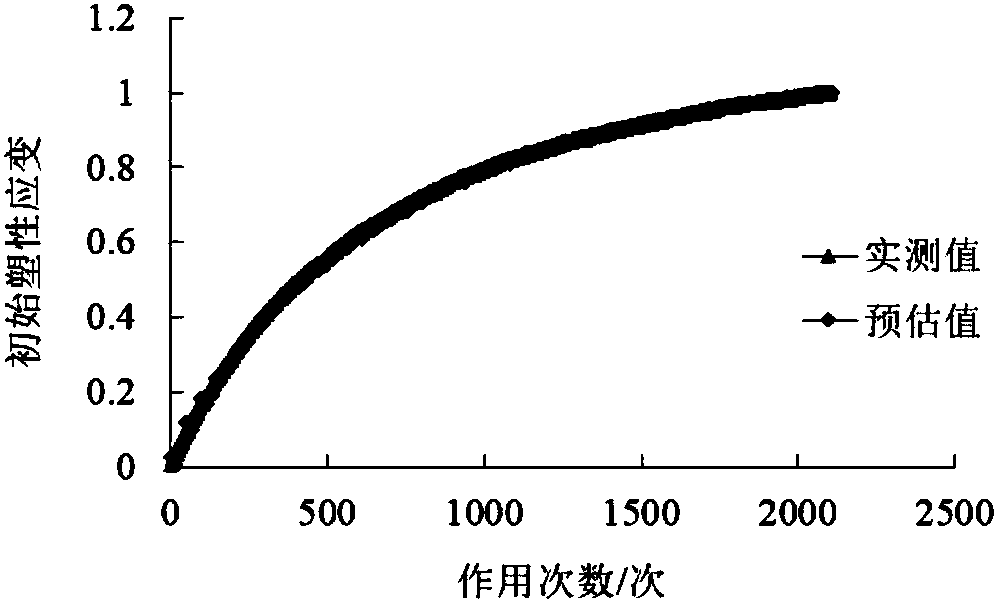

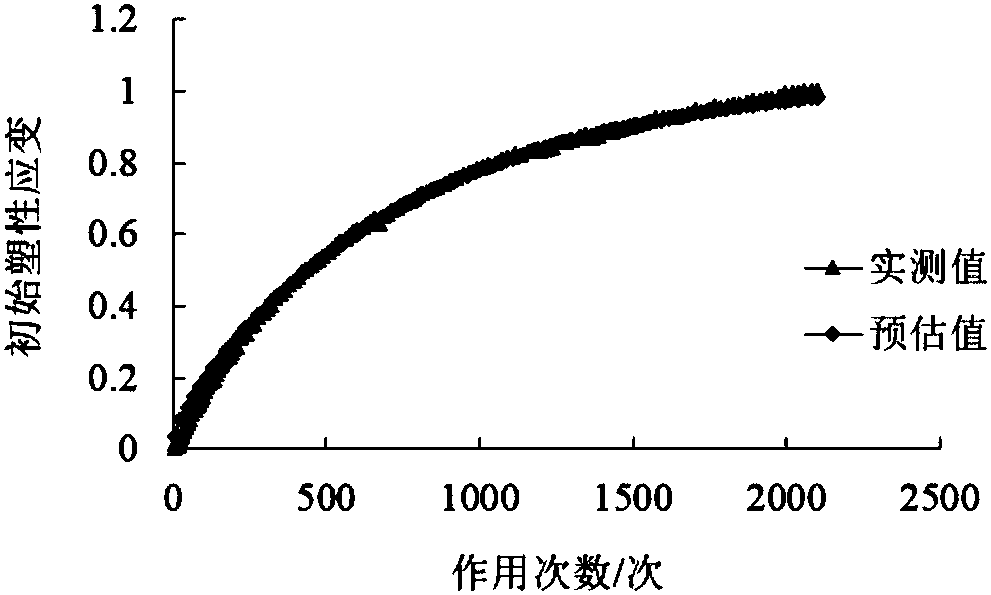

[0028] 1. Selection of plastic strain prediction model;

[0029] The plastic strain prediction model shown in formula (2) is selected:

[0030]

[0031] Where: ε p is the initial plastic strain;

[0032] d t,p is the plastic deformation amount of graded crushed stone at each moment in the plastic deformation test, mm;

[0033] d 60,p In the plastic deformation test, the plastic deformation of the graded crushed stone at the 60th minute, mm;

[0034] N is the equivalent axis acting on the graded crushed stone, times;

[0035] A, B, C, D, E are model coefficients;

[0036] h is the thickness of graded gravel, mm.

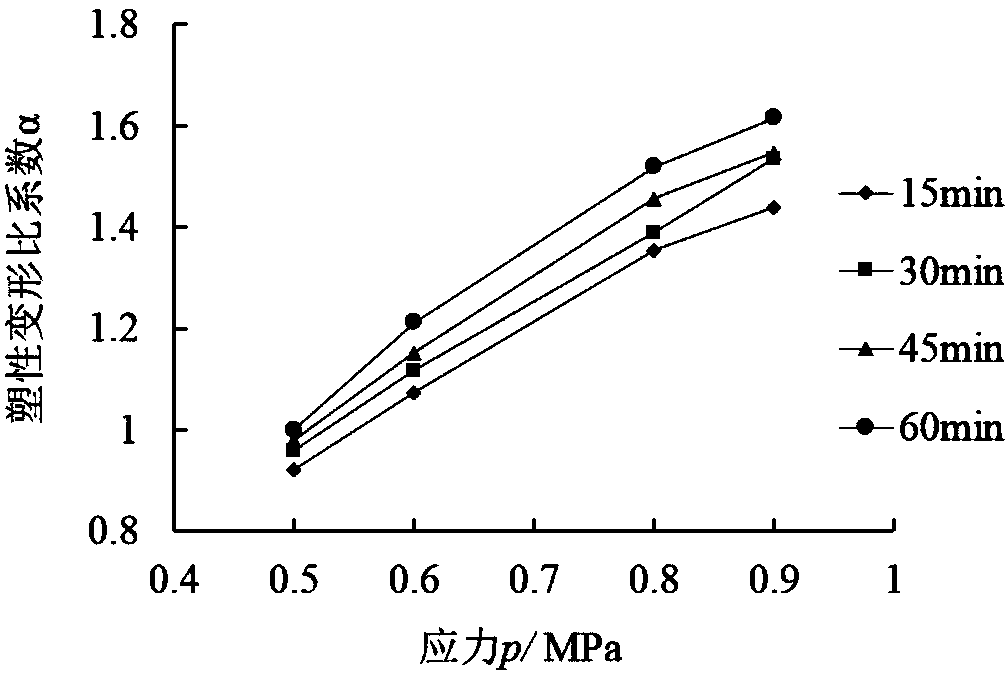

[0037] 2. Calibration of model coefficients A, B, C, D, E;

[0038] The calibration of model coefficients A, B, C, D, E is based on plastic deformation tests.

[0039] The gradation of selected crushed stone aggregates is shown in Table 1. The vibration compactio...

Embodiment 2

[0103] Application of plastic deformation prediction method for graded crushed stone base;

[0104] The asphalt pavement structure of a highway graded gravel base is shown in Table 11. Try to estimate the graded crushed stone base at 1.0×10 7 The amount of plastic deformation under the action of the equivalent axis. Among them, the gradation used in the graded crushed stone base in this example is the GM gradation in Table 1.

[0105] Table 11 Pavement Structure

[0106]

[0107] 1. Graded crushed stone base layer;

[0108] Since the thickness of the graded crushed stone base is 18cm, it is divided into two layers, the upper layer h 1 =10cm, lower layer h 2 = 8cm.

[0109] 2. The vertical compressive force p in each layer of the graded crushed stone base i calculate;

[0110] Calculate the vertical compressive stress p in the two layers of the graded crushed stone base when the standard shaft load acts on the surface of the asphalt pavement i , the results are show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com