Intelligent formulating method for sewing process parameters of turned edge of lower hem of woven fabric

A technology for process parameters and woven fabrics is applied in the field of intelligent formulation of process parameters for hem hemming sewing of woven fabrics. and cost, the effect of high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

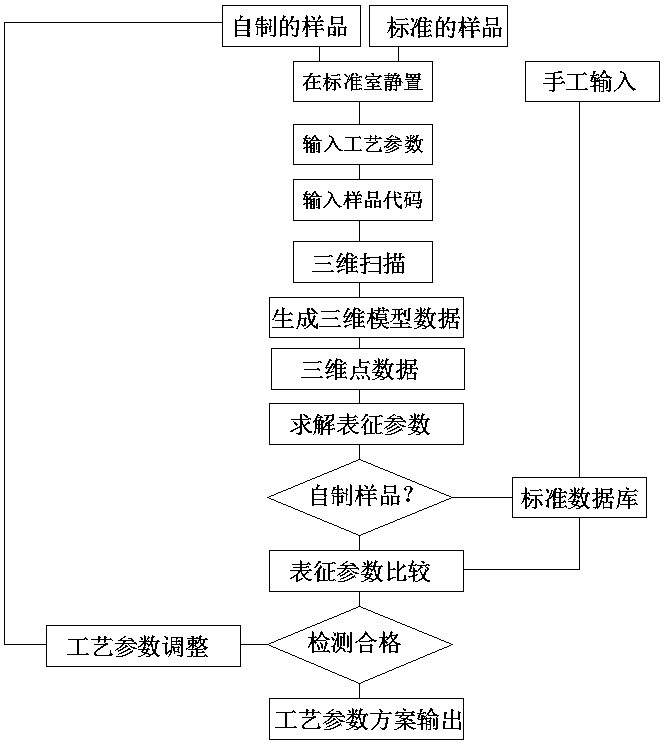

[0092] The method is to detect the flatness of hem appearance sewing for a standard sample or a self-made sample, the detection data of the standard sample is stored in the standard database and called, and the detection data of the self-made sample and the parameters of the corresponding object in the standard database Carry out analysis and comparison, and then analyze and process to give the sewing process parameters of the specified product;

[0093] The method comprises the steps of:

[0094] Step 1: Sample Selection

[0095] Select a standard sample that is a product that has been evaluated by an authoritative institution, or,

[0096] Select a piece of fabric with a specified size, and the sewing worker completes the specified self-rolling sewing on the specified sewing machine according to the specified process requirements to form a self-made sample;

[0097] Step 2: The sample is left in a standard room for 24 hours; in this embodiment, the temperature in the stand...

Embodiment 2

[0128] Basically the same as Example 1, the difference is: the calculation method of the actual curved surface area SA of the sample is SA=S 1 +S 2 +…+S k; The calculation method of the projected area SB of the sample is SB=S 1 cosθ 1+S 2 cosθ 2 +…+S k cosθ k .

Embodiment 3,4

[0130] They are basically the same as Embodiments 1 and 2, except that the Handyscan 3D series hand-held self-positioning 3D laser scanner and its software developed by Creaform Company are used in the 3D scanning process.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap