Alarm method and electronic device for abnormal working condition of coal cutter, and medium

A shearer and working condition technology, applied in mining equipment, slitting machinery, earthwork drilling and other directions, can solve the problem of attenuating the service life of the drum, reducing the cutting efficiency of the shearer, and unable to accurately perceive the abnormal working conditions of the shearer And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

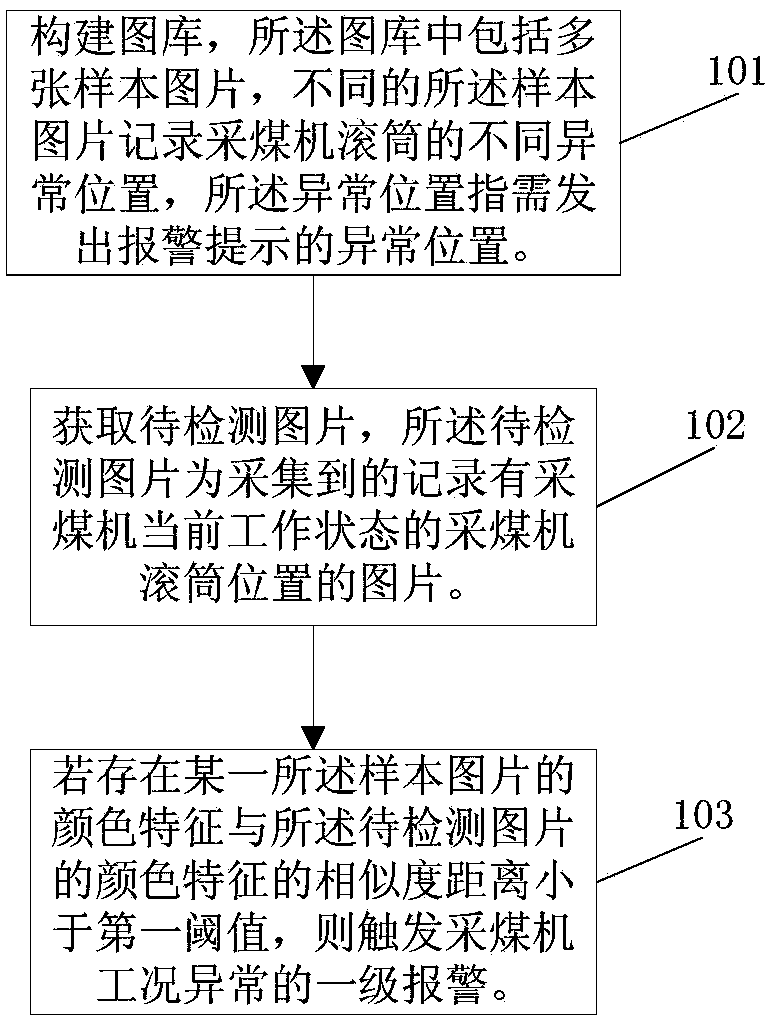

[0042] This embodiment provides an alarm method for abnormal working conditions of a shearer. In this method, the abnormal position of the shearer drum is used to identify the abnormal working condition of the shearer. First, the sample picture showing the abnormal position of the shearer drum is saved. In the gallery, the similarity distance between the picture to be detected and the sample picture taken in real time at the coal mining site is calculated based on the color features, and an alarm for abnormal working conditions of the coal mining machine is triggered based on the similarity distance.

[0043] Such as figure 1 As shown, the steps of the alarm method for abnormal working conditions of the shearer provided in this embodiment are as follows:

[0044] 101. Build a gallery, the gallery includes multiple sample pictures, and different sample pictures record different abnormal positions of the shearer drum, and the abnormal positions refer to the abnormal positions th...

Embodiment 2

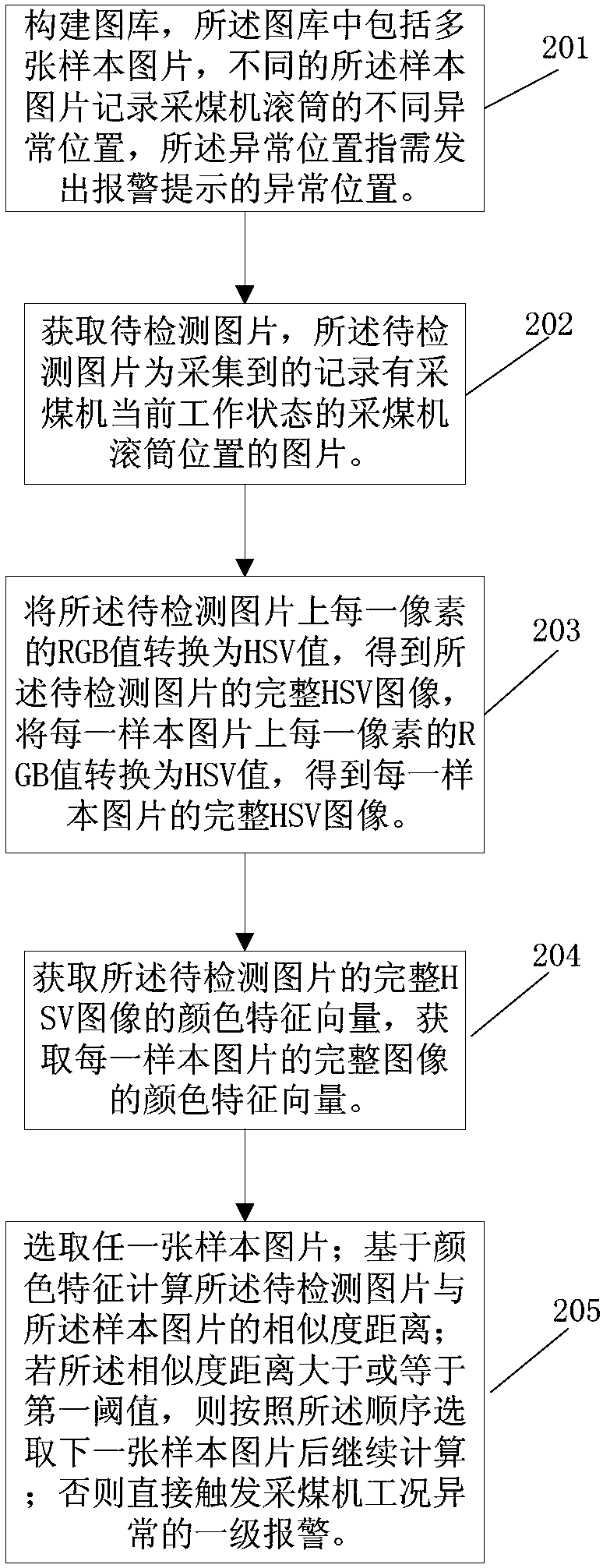

[0054] This embodiment provides an alarm method for abnormal working conditions of a coal shearer. The method calculates the similarity distance between the picture to be detected and a sample picture based on the color characteristics of the complete image. If the similarity between the picture to be detected and a certain sample picture is If the degree distance is less than the first threshold, the calculation is stopped, and an alarm of abnormal working condition of the shearer is triggered.

[0055] Such as figure 2 As shown, the steps of the alarm method for abnormal working conditions of the shearer provided in this embodiment are as follows:

[0056] 201. Build a gallery, the gallery includes a plurality of sample pictures, and different sample pictures record different abnormal positions of the shearer drum, and the abnormal positions refer to abnormal positions where alarm prompts need to be issued.

[0057] Please refer to the description of step 101 in the first ...

Embodiment 3

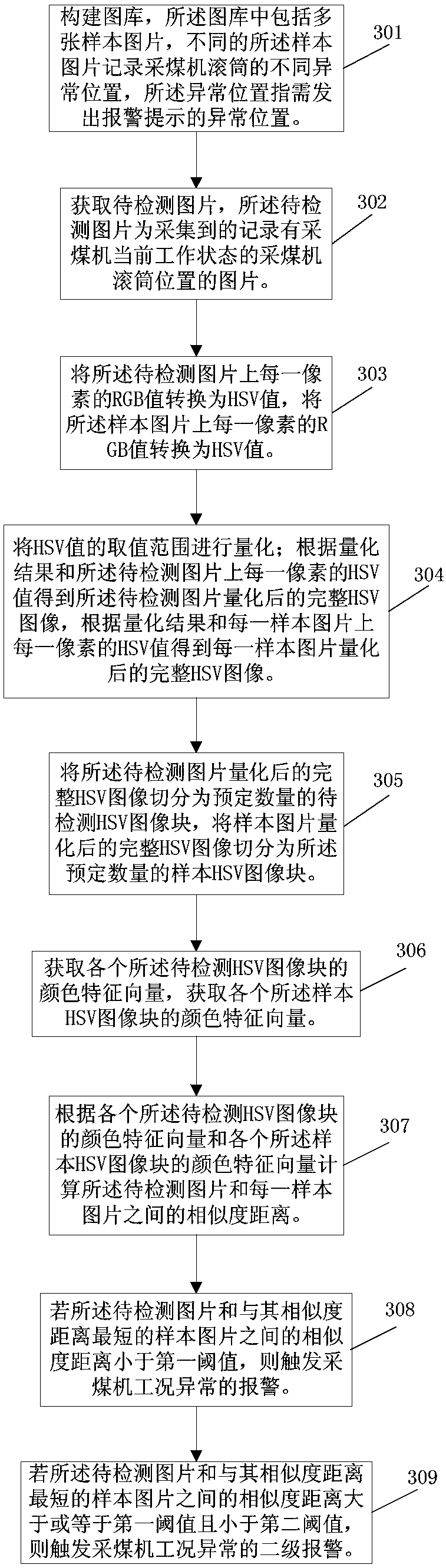

[0078] This embodiment provides an alarm method for abnormal working conditions of a coal shearer. The method calculates the similarity distance between the image to be detected and each sample image based on the color characteristics of the image block. If the image to be detected and the image with the shortest similarity distance If the similarity distance between the sample pictures is less than the first threshold, it will trigger a first-level alarm for abnormal working conditions of the coal shearer; if the similarity distance between the picture to be detected and the sample picture with the shortest similarity distance is greater than or equal to the first Threshold and less than the second threshold, a secondary alarm for abnormal working conditions of the coal shearer will be triggered.

[0079] Such as image 3 As shown, the steps of the alarm method for abnormal working conditions of the shearer provided in this embodiment are as follows:

[0080] 301. Build a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com