GIS insulator surface charge accumulation inhibition method based on linear gradient treatment

A surface charge and insulator technology, applied in the field of modified polymer materials and their preparation, can solve the problems of increasing the occurrence of surface flashover, local field strength distortion along the surface of basin insulators, frequent insulator failures, etc., and improve the operation stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Mix the epoxy resin base and curing agent according to the mass ratio of 3:1, and use a mechanical stirrer to stir for 60 minutes to make it evenly mixed; then use an air pump and a vacuum box to degas the epoxy resin mixture for 40 minutes, , the vacuum degree is -0.1MPa; then pour it into a mold coated with a release agent, solidify, cool, and demould, that is.

[0041] 2) Epoxy resin materials are processed by gradient temperature curing method. The curing process is divided into two steps. First, the mold and base material are heated to 70°C for 4 hours, and then heated to 130°C for 4 hours. After complete curing, cool down , Demoulding promptly obtains the epoxy resin insulation sample.

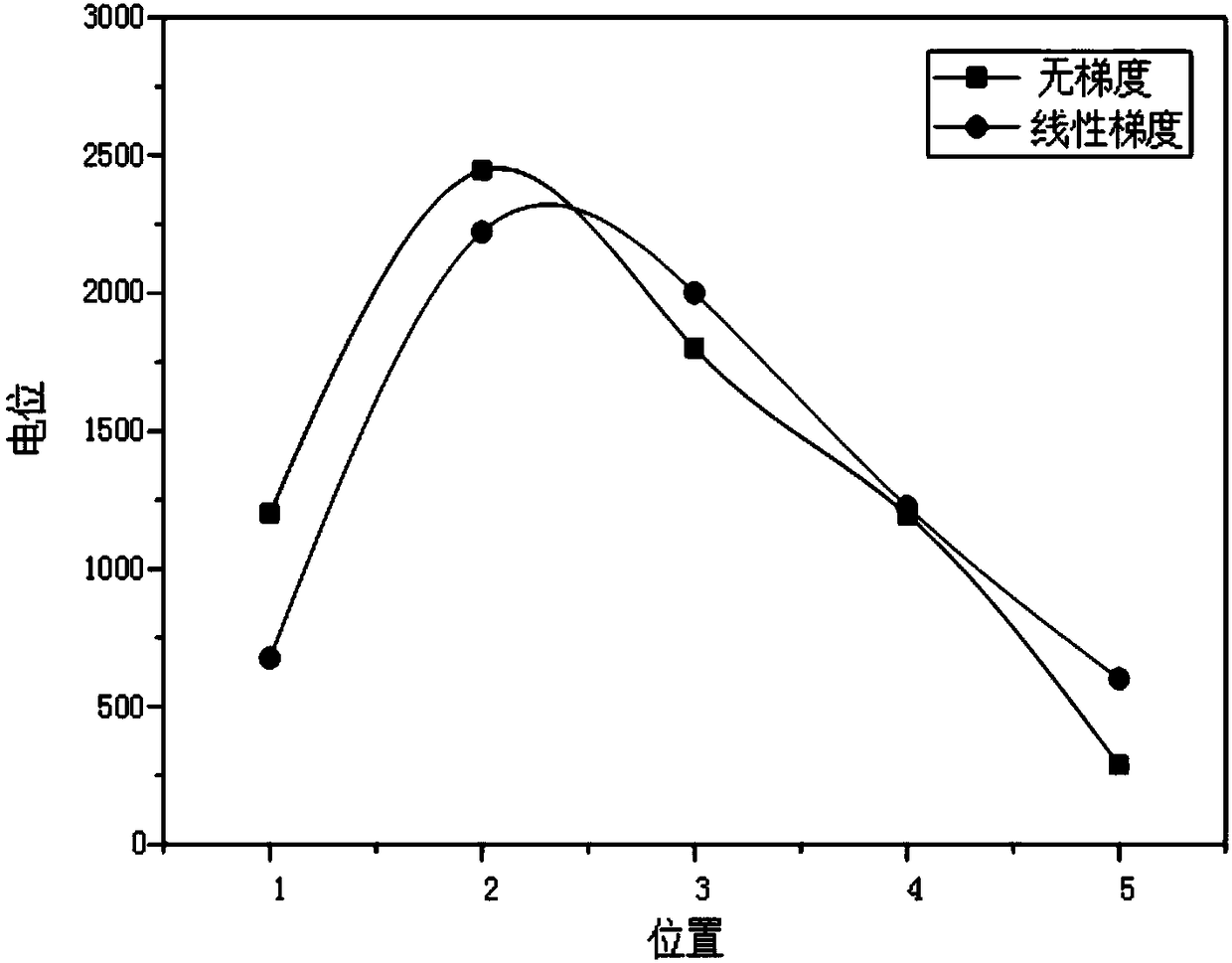

[0042] 3) Gradient design is carried out on the epoxy resin insulation sample according to the strip pattern, that is, its surface is divided into five closely connected rectangles from left to right, and the relative permittivity of the rectangles is reduced in turn: the epoxy...

Embodiment 2

[0046] 1) Mix the epoxy resin base and curing agent according to the mass ratio of 3:1, and use a mechanical stirrer to stir for 90 minutes to make it evenly mixed; then use an air pump and a vacuum box to degas the epoxy resin mixture for 60 minutes, , the vacuum degree is -0.1MPa, and then it is poured into a mold coated with a release agent, solidified, cooled, and demoulded, and the product is obtained.

[0047] 2) Epoxy resin is processed by gradient temperature curing method. The curing process is divided into two steps. First, heat the mold and base material to 70°C for 4 hours, and then heat to 130°C for 4 hours. After complete curing, cool, The epoxy resin insulation sample can be obtained after demoulding.

[0048] 3) The epoxy resin insulation sample is designed according to the gradient of the ring pattern, that is, its surface is divided into five closely connected rings from the inside to the outside, and the relative permittivity of the rings is reduced in turn:...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap